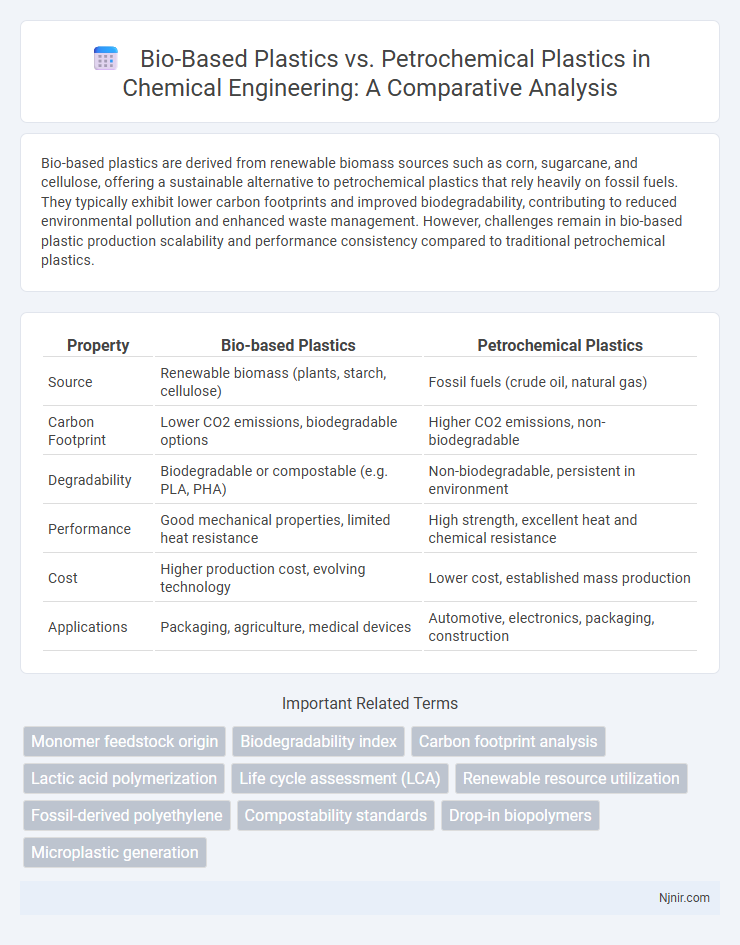

Bio-based plastics are derived from renewable biomass sources such as corn, sugarcane, and cellulose, offering a sustainable alternative to petrochemical plastics that rely heavily on fossil fuels. They typically exhibit lower carbon footprints and improved biodegradability, contributing to reduced environmental pollution and enhanced waste management. However, challenges remain in bio-based plastic production scalability and performance consistency compared to traditional petrochemical plastics.

Table of Comparison

| Property | Bio-based Plastics | Petrochemical Plastics |

|---|---|---|

| Source | Renewable biomass (plants, starch, cellulose) | Fossil fuels (crude oil, natural gas) |

| Carbon Footprint | Lower CO2 emissions, biodegradable options | Higher CO2 emissions, non-biodegradable |

| Degradability | Biodegradable or compostable (e.g. PLA, PHA) | Non-biodegradable, persistent in environment |

| Performance | Good mechanical properties, limited heat resistance | High strength, excellent heat and chemical resistance |

| Cost | Higher production cost, evolving technology | Lower cost, established mass production |

| Applications | Packaging, agriculture, medical devices | Automotive, electronics, packaging, construction |

Introduction to Bio-based and Petrochemical Plastics

Bio-based plastics are derived from renewable biological sources such as corn starch, sugarcane, and cellulose, offering a sustainable alternative to traditional petrochemical plastics made from fossil fuels like crude oil and natural gas. These plastics can be biodegradable or non-biodegradable, depending on their chemical structure and production process. Petrochemical plastics, including polyethylene, polypropylene, and polystyrene, dominate the market due to their durability and versatility but raise environmental concerns due to their persistence and carbon footprint.

Raw Materials and Resource Origin

Bio-based plastics are derived from renewable biomass sources such as corn starch, sugarcane, and cellulose, reducing dependence on finite fossil fuels and minimizing carbon footprint. Petrochemical plastics originate from non-renewable petroleum and natural gas, contributing to resource depletion and environmental pollution. The use of renewable raw materials in bio-based plastics supports sustainable production and circular economy principles.

Manufacturing Processes and Energy Consumption

Bio-based plastics are produced through the fermentation and polymerization of renewable biomass such as corn, sugarcane, or cellulose, requiring less fossil fuel input compared to petrochemical plastics, which originate from crude oil refining via cracking and polymerization. Manufacturing bio-based plastics generally consumes lower energy due to processes like enzymatic conversion and green chemistry techniques, while petrochemical plastics often demand higher energy-intensive thermal and catalytic processes. Energy consumption for bio-based plastics varies with feedstock type and process efficiency, but life cycle assessments typically show reduced greenhouse gas emissions relative to conventional petrochemical plastic production.

Mechanical and Physical Properties Comparison

Bio-based plastics such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA) often exhibit lower tensile strength and impact resistance compared to traditional petrochemical plastics like polyethylene (PE) and polypropylene (PP), limiting their use in high-stress applications. However, bio-based plastics generally provide comparable thermal stability and offer superior UV resistance and biodegradability, enhancing their environmental performance without sacrificing mechanical integrity in certain uses. Differences in crystallinity and molecular structure between bio-based and petrochemical polymers influence properties such as flexibility, stiffness, and moisture absorption, critical factors in packaging and automotive industries.

Environmental Impact Assessment

Bio-based plastics typically demonstrate lower greenhouse gas emissions and reduced fossil fuel dependency compared to petrochemical plastics, contributing to a smaller carbon footprint throughout their lifecycle. However, their environmental impact assessment must consider land use changes, water consumption, and potential competition with food crops. Petrochemical plastics often pose significant challenges related to pollution, non-biodegradability, and microplastic accumulation in ecosystems, emphasizing the need for comprehensive impact evaluations.

Biodegradability and End-of-Life Options

Bio-based plastics, often derived from renewable resources such as corn starch or sugarcane, typically offer improved biodegradability compared to conventional petrochemical plastics which are primarily made from fossil fuels like crude oil and natural gas. Many bio-based plastics, such as polylactic acid (PLA), can break down under industrial composting conditions, reducing landfill waste and environmental pollution. In contrast, petrochemical plastics generally require long-term recycling or remain in landfills for centuries, posing significant challenges for end-of-life management and contributing to plastic pollution.

Economic Considerations and Scalability

Bio-based plastics often face higher production costs compared to petrochemical plastics due to reliance on agricultural feedstocks and less mature manufacturing processes, impacting overall economic viability. Petrochemical plastics benefit from well-established, large-scale production infrastructure and lower raw material costs, making them more scalable for mass production. However, recent advances in bio-based polymer technology and increasing economies of scale are gradually narrowing the cost gap, enhancing the commercial potential of bio-based alternatives.

Applications in Industry and Consumer Products

Bio-based plastics are increasingly utilized in packaging, agriculture, and consumer goods due to their biodegradability and reduced carbon footprint, offering sustainable alternatives for single-use items and food containers. Petrochemical plastics dominate automotive, aerospace, and electronics industries because of their superior durability, heat resistance, and cost-effectiveness in mass production. The shift towards bio-based plastics in consumer products addresses environmental concerns, while petrochemical plastics continue to meet high-performance requirements in industrial applications.

Regulatory Landscape and Certification Standards

Bio-based plastics face evolving regulatory frameworks that emphasize environmental impact, such as the European Union's Circular Economy Action Plan promoting sustainable materials and restricting single-use plastics. Certification standards like the ASTM D6400 for compostability and the TUV AUSTRIA OK biobased label ensure compliance with biodegradability and renewable content criteria. Petrochemical plastics remain governed by established regulations focused on product safety and emissions, while ongoing policy shifts encourage substitution with bio-based alternatives to reduce carbon footprint.

Future Trends and Innovations in Plastics Engineering

Future trends in plastics engineering emphasize the development of bio-based plastics derived from renewable resources like plant starch, cellulose, and algae, offering enhanced biodegradability and reduced carbon footprints compared to traditional petrochemical plastics. Innovations include advanced polymer blends and bio-composites that improve mechanical properties and thermal stability while maintaining eco-friendly characteristics. Research in enzymatic recycling and chemical upcycling further supports circular economy goals by enabling efficient degradation and reuse of both bio-based and petrochemical plastic materials.

Monomer feedstock origin

Bio-based plastics are derived from renewable biomass monomers such as corn or sugarcane, while petrochemical plastics originate from non-renewable fossil fuel-based monomers like ethylene and propylene.

Biodegradability index

Bio-based plastics typically exhibit a higher biodegradability index than petrochemical plastics, enabling faster decomposition and reduced environmental impact.

Carbon footprint analysis

Bio-based plastics typically exhibit a 30-70% lower carbon footprint compared to petrochemical plastics due to renewable feedstocks and reduced greenhouse gas emissions during production.

Lactic acid polymerization

Lactic acid polymerization produces bio-based polylactic acid (PLA), offering a biodegradable and renewable alternative to petrochemical plastics with comparable mechanical properties and lower environmental impact.

Life cycle assessment (LCA)

Bio-based plastics often demonstrate lower carbon footprints and reduced fossil fuel consumption in life cycle assessments compared to petrochemical plastics, but factors such as land use, water consumption, and end-of-life disposal critically influence their overall environmental impact.

Renewable resource utilization

Bio-based plastics utilize renewable resources such as corn, sugarcane, and cellulose, significantly reducing reliance on finite petrochemical sources derived from crude oil and natural gas.

Fossil-derived polyethylene

Fossil-derived polyethylene, primarily sourced from petrochemical processes, significantly contributes to environmental pollution and carbon emissions compared to sustainable, biodegradable bio-based plastics.

Compostability standards

Bio-based plastics certified under ASTM D6400 and EN 13432 standards demonstrate higher compostability compared to conventional petrochemical plastics, which typically lack approved compostability certifications.

Drop-in biopolymers

Drop-in biopolymers derived from renewable biomass seamlessly replace petrochemical plastics in existing manufacturing processes while reducing carbon footprint and enhancing sustainability.

Microplastic generation

Bio-based plastics generate significantly fewer microplastics compared to petrochemical plastics due to their biodegradable properties and natural polymer composition.

Bio-based plastics vs Petrochemical plastics Infographic

njnir.com

njnir.com