Hybrid separation combines multiple techniques such as distillation and membrane filtration to enhance efficiency and selectivity, outperforming single-mode separation methods that rely on one primary process. This approach reduces energy consumption and operational costs by optimizing separation stages tailored to specific compound properties. Hybrid systems are particularly advantageous in handling complex mixtures and achieving higher purity levels compared to traditional single-mode separations.

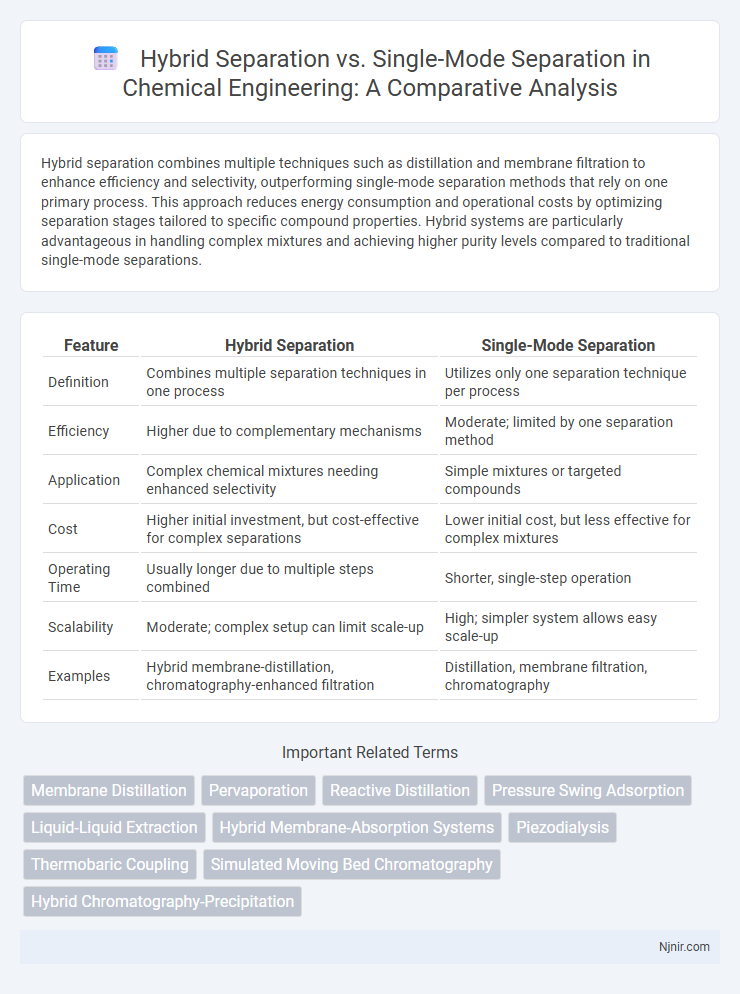

Table of Comparison

| Feature | Hybrid Separation | Single-Mode Separation |

|---|---|---|

| Definition | Combines multiple separation techniques in one process | Utilizes only one separation technique per process |

| Efficiency | Higher due to complementary mechanisms | Moderate; limited by one separation method |

| Application | Complex chemical mixtures needing enhanced selectivity | Simple mixtures or targeted compounds |

| Cost | Higher initial investment, but cost-effective for complex separations | Lower initial cost, but less effective for complex mixtures |

| Operating Time | Usually longer due to multiple steps combined | Shorter, single-step operation |

| Scalability | Moderate; complex setup can limit scale-up | High; simpler system allows easy scale-up |

| Examples | Hybrid membrane-distillation, chromatography-enhanced filtration | Distillation, membrane filtration, chromatography |

Introduction to Separation Techniques in Chemical Engineering

Hybrid separation combines multiple separation methods, such as membrane filtration with distillation, enhancing efficiency and selectivity in complex mixtures. Single-mode separation relies on one technique--like chromatography or extraction--suitable for simpler, less diverse components. Chemical engineers select hybrid methods to optimize energy consumption and achieve higher purity levels in industrial processes.

Defining Hybrid and Single-Mode Separation Processes

Hybrid separation processes combine multiple separation techniques, such as membrane filtration paired with adsorption or distillation, to enhance efficiency and selectivity in complex mixtures. Single-mode separation relies on one distinct method, like only membrane filtration or solely distillation, targeting specific properties such as molecular size or volatility. The hybrid approach often achieves higher purity and energy savings by leveraging complementary mechanisms, whereas single-mode processes provide simplicity and lower operational costs.

Principles of Single-Mode Separation Methods

Single-mode separation methods rely on a single physical principle such as size exclusion, charge, or affinity to isolate target molecules, ensuring high specificity and reproducibility in analytical and preparative processes. Techniques like gel filtration, ion exchange chromatography, and affinity chromatography exemplify single-mode separation by exploiting molecular size, ionic interactions, or specific binding affinities, respectively. These methods offer advantages in controlled separation conditions and predictability, but may lack the versatility of hybrid separation systems that combine multiple principles for enhanced selectivity and resolution.

Fundamentals of Hybrid Separation Technologies

Hybrid separation technologies combine multiple separation mechanisms, such as membrane filtration and adsorption, to enhance selectivity and efficiency beyond single-mode separation methods. These systems leverage synergistic effects between physical and chemical processes, enabling the effective separation of complex mixtures and contaminants. The fundamental principle involves optimizing each separation mode's strengths to achieve superior purity, throughput, and energy savings compared to traditional single-mode approaches.

Comparative Performance: Efficiency and Selectivity

Hybrid separation systems combine multiple separation techniques, optimizing efficiency by leveraging complementary mechanisms, resulting in higher throughput and enhanced selectivity compared to single-mode separation methods. Single-mode separation often exhibits limitations in resolving complex mixtures due to reliance on a singular separation principle, which can reduce efficiency and selectivity under challenging conditions. Studies demonstrate hybrid approaches achieve superior separation performance by minimizing cross-contamination and maximizing target compound isolation in diverse industrial and analytical applications.

Energy Consumption and Sustainability Considerations

Hybrid separation technologies combine multiple separation processes, significantly reducing energy consumption by optimizing the use of each method, whereas single-mode separation often relies on a single, energy-intensive process. Studies show hybrid systems cut energy use by up to 40%, contributing to lower greenhouse gas emissions and improved sustainability metrics. This energy efficiency positions hybrid separation as a more environmentally sustainable option in industrial applications, aligning better with global energy reduction targets.

Application Areas: Industrial and Laboratory Scenarios

Hybrid separation techniques combine the advantages of multiple separation mechanisms, making them ideal for complex industrial applications such as petrochemical processing and pharmaceutical production, where high selectivity and throughput are critical. Single-mode separation methods, including distillation, filtration, or chromatography, are often preferred in laboratory scenarios due to their simplicity, ease of control, and suitability for analyzing specific components in research and quality control. Industrial settings benefit from hybrid approaches for enhanced efficiency and scalability, whereas laboratories prioritize single-mode techniques for precision and reproducibility in sample analysis.

Challenges and Limitations of Hybrid Systems

Hybrid separation systems face challenges such as complex integration of diverse separation techniques, leading to increased operational costs and maintenance requirements. Scaling hybrid systems can be limited by energy consumption and the need for precise control of multiple parameters to maintain separation efficiency. Additionally, hybrid technology often requires specialized expertise and advanced materials, which can hinder widespread adoption and increase implementation barriers.

Economic Analysis: Cost-Benefit Perspectives

Hybrid separation systems often deliver superior economic efficiency compared to single-mode separation by optimizing operational costs and enhancing throughput capacity. Incorporating multiple separation technologies allows for greater flexibility in handling diverse feedstocks, reducing energy consumption and maintenance expenses. Investment in hybrid systems can yield higher return on investment (ROI) due to improved separation performance and lower overall lifecycle costs.

Future Trends and Innovations in Separation Technologies

Hybrid separation techniques combine the advantages of multiple separation methods, enhancing efficiency and selectivity in chemical and industrial processes compared to traditional single-mode separation, which relies on one primary mechanism such as membrane filtration or distillation. Emerging innovations in hybrid systems involve integrating advanced materials like graphene-based membranes and AI-driven process optimization to achieve higher throughput, lower energy consumption, and greater adaptability to complex mixtures. Future trends emphasize sustainability and scalability, with ongoing research focused on modular, hybrid platforms that can dynamically switch or combine separation modes to meet evolving industrial demands.

Membrane Distillation

Hybrid separation systems combining membrane distillation with single-mode separation techniques enhance contaminant removal efficiency and energy savings compared to standalone membrane distillation processes.

Pervaporation

Hybrid separation integrating pervaporation with single-mode separation enhances selectivity and flux efficiency for organic solvent recovery compared to standalone single-mode pervaporation membranes.

Reactive Distillation

Reactive distillation combines reaction and separation in a single unit, enhancing efficiency compared to single-mode separation by continuously converting reactants and separating products, while hybrid separation integrates multiple separation techniques to optimize purification and energy use.

Pressure Swing Adsorption

Pressure Swing Adsorption (PSA) in hybrid separation systems enhances gas purity and recovery by combining multiple adsorption steps, outperforming traditional single-mode PSA through improved selectivity and lower energy consumption.

Liquid-Liquid Extraction

Hybrid separation combines liquid-liquid extraction with complementary techniques to enhance separation efficiency and selectivity compared to single-mode liquid-liquid extraction methods.

Hybrid Membrane-Absorption Systems

Hybrid membrane-absorption systems combine selective membrane separation with chemical absorption, enhancing CO2 capture efficiency and reducing energy consumption compared to single-mode separation methods.

Piezodialysis

Piezodialysis in hybrid separation systems enhances molecular selectivity and permeability beyond single-mode separation by integrating piezoelectric-driven filtration with conventional membrane techniques.

Thermobaric Coupling

Hybrid separation enhances efficiency over single-mode separation by leveraging thermobaric coupling to optimize pressure and temperature interactions during phase transitions.

Simulated Moving Bed Chromatography

Simulated Moving Bed Chromatography enhances Hybrid Separation efficiency by combining continuous single-mode separation with multicomponent adsorption for superior purity and yield.

Hybrid Chromatography-Precipitation

Hybrid chromatography-precipitation combines chromatographic separation with precipitation techniques to enhance selectivity and purity compared to single-mode separation methods.

Hybrid Separation vs Single-Mode Separation Infographic

njnir.com

njnir.com