Traditional catalysis relies on inorganic catalysts that operate under harsh conditions, often requiring high temperatures and pressures to accelerate chemical reactions. Enzyme catalysis offers a biocatalytic approach, utilizing highly specific and efficient proteins that function under mild, environmentally friendly conditions with exceptional selectivity. This specificity and mild operational environment make enzyme catalysis particularly advantageous for sustainable chemical processes and complex molecule synthesis.

Table of Comparison

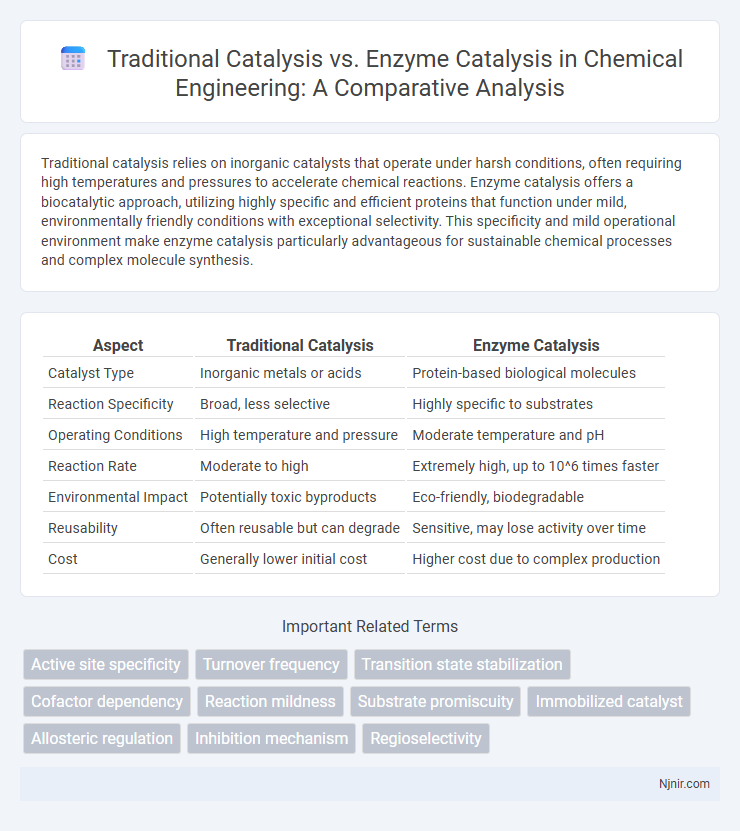

| Aspect | Traditional Catalysis | Enzyme Catalysis |

|---|---|---|

| Catalyst Type | Inorganic metals or acids | Protein-based biological molecules |

| Reaction Specificity | Broad, less selective | Highly specific to substrates |

| Operating Conditions | High temperature and pressure | Moderate temperature and pH |

| Reaction Rate | Moderate to high | Extremely high, up to 10^6 times faster |

| Environmental Impact | Potentially toxic byproducts | Eco-friendly, biodegradable |

| Reusability | Often reusable but can degrade | Sensitive, may lose activity over time |

| Cost | Generally lower initial cost | Higher cost due to complex production |

Introduction to Catalysis in Chemical Engineering

Traditional catalysis in chemical engineering relies on solid acids, metals, or metal oxides to accelerate reactions through surface interactions, offering robustness in high-temperature processes. Enzyme catalysis utilizes biological macromolecules like proteins to perform highly selective and efficient transformations under mild conditions, leveraging active sites tailored for specific substrates. Comparing these methods highlights differences in reaction specificity, operational environment, and catalyst regeneration, essential for designing sustainable and application-specific catalytic systems.

Fundamentals of Traditional Catalysis

Traditional catalysis relies on inorganic or organic catalysts to accelerate chemical reactions by lowering activation energy through surface interactions or active sites without being consumed in the process. It typically involves heterogeneous catalysts such as metals, metal oxides, or zeolites that provide specific adsorption sites for reactants, facilitating bond breaking and formation. Key principles include catalyst surface area, electronic structure, and reaction conditions, which influence catalyst activity, selectivity, and stability in industrial applications.

Overview of Enzyme Catalysis Mechanisms

Enzyme catalysis operates through highly specific active sites that stabilize transition states and lower activation energy, allowing biochemical reactions to proceed efficiently under mild physiological conditions. Mechanisms include acid-base catalysis, covalent catalysis, metal ion catalysis, and substrate orientation, each contributing to enhanced reaction rates and selectivity. Enzymes leverage dynamic conformational changes to facilitate substrate binding and product release, distinguishing enzyme catalysis from traditional catalysis methods that often rely on harsher conditions and less specificity.

Key Differences Between Traditional and Enzyme Catalysis

Traditional catalysis typically involves inorganic or metal catalysts that lower activation energy through surface interactions, often requiring high temperatures and pressures, whereas enzyme catalysis uses highly specific protein catalysts that operate efficiently under mild biological conditions. Enzymes enhance reaction rates by stabilizing transition states and binding substrates precisely in their active sites, leading to remarkable substrate specificity and reaction selectivity compared to the broader reactivity of traditional catalysts. Unlike traditional catalysts, enzymes can be regulated and inhibited through feedback mechanisms, allowing dynamic control within biological systems.

Catalyst Efficiency and Selectivity: A Comparative Analysis

Traditional catalysis often relies on metal-based catalysts that provide moderate efficiency and selectivity in chemical reactions, frequently requiring harsh conditions such as high temperatures and pressures. Enzyme catalysis exhibits extraordinary efficiency and substrate selectivity due to the highly specific active sites and mild operating conditions, achieving turnover numbers far exceeding traditional catalysts. Comparative analyses highlight enzymes' ability to accelerate reactions with unparalleled precision, reducing side-product formation and enhancing overall reaction sustainability.

Reaction Conditions: Temperature, Pressure, and Solvents

Traditional catalysis often requires harsh reaction conditions, including high temperatures and pressures, as well as the use of organic solvents to achieve desired reaction rates and selectivities. Enzyme catalysis operates efficiently under mild conditions, typically near physiological temperature (20-40degC), atmospheric pressure, and aqueous environments, reducing energy consumption and environmental impact. The specificity and catalytic efficiency of enzymes enable biochemical transformations that are difficult or impossible under traditional catalytic conditions.

Sustainability and Environmental Impact

Traditional catalysis often relies on metal-based catalysts that can be toxic, non-renewable, and generate hazardous waste, posing significant sustainability challenges. Enzyme catalysis utilizes biocatalysts derived from renewable biological sources, operating under mild conditions to minimize energy consumption and reduce harmful byproducts. This sustainable approach promotes biodegradability and lower environmental impact, aligning with green chemistry principles for eco-friendly industrial processes.

Industrial Applications: Traditional vs Enzyme Catalysts

Traditional catalysis in industrial applications relies heavily on metal-based catalysts and harsh reaction conditions, often leading to lower selectivity and higher energy consumption. Enzyme catalysis offers enhanced specificity and operates under mild conditions, significantly improving product yield and reducing environmental impact in industries such as pharmaceuticals, food processing, and biofuels. Industrial enzyme catalysts enable sustainable processes by minimizing hazardous byproducts and facilitating biocatalytic reactions that are challenging for traditional catalysts.

Challenges in Catalyst Design and Process Integration

Traditional catalysis faces challenges in achieving high selectivity and reaction specificity due to limited active site precision, often requiring harsh conditions that reduce catalyst lifespan. Enzyme catalysis offers superior substrate specificity and operates under mild conditions but struggles with stability, scalability, and integration into industrial processes. Designing robust biocatalysts and optimizing process parameters remain critical hurdles to fully harness enzyme potential in large-scale applications.

Future Trends in Catalysis Research and Development

Traditional catalysis relies heavily on harsh conditions and non-specific catalysts, whereas enzyme catalysis offers high specificity and operates under mild conditions, driving greener and more sustainable chemical processes. Future trends in catalysis research emphasize the integration of artificial intelligence and machine learning to design custom enzymes with enhanced stability and activity for industrial applications. Advances in protein engineering and synthetic biology are expected to expand enzyme catalysis into new reaction types, improving efficiency and selectivity while reducing environmental impact.

Active site specificity

Enzyme catalysis exhibits high active site specificity by precisely binding substrates through unique three-dimensional structures, whereas traditional catalysis often relies on broader surface interactions with less substrate selectivity.

Turnover frequency

Enzyme catalysis exhibits significantly higher turnover frequency compared to traditional catalysis due to its highly specific active sites and efficient substrate binding.

Transition state stabilization

Enzyme catalysis enhances reaction rates by selectively stabilizing the transition state through precise substrate binding and induced fit mechanisms, whereas traditional catalysis primarily relies on general chemical properties or external conditions to lower activation energy.

Cofactor dependency

Traditional catalysis often relies on metal ions or synthetic cofactors, whereas enzyme catalysis depends on specific organic or metal-based cofactors to achieve high substrate specificity and reaction efficiency.

Reaction mildness

Enzyme catalysis operates under milder conditions such as ambient temperature and neutral pH, whereas traditional catalysis often requires high temperatures, extreme pH, and harsh chemicals.

Substrate promiscuity

Enzyme catalysis exhibits higher substrate promiscuity than traditional catalysis, enabling enzymes to efficiently convert a broader range of structurally diverse substrates under mild conditions.

Immobilized catalyst

Immobilized enzyme catalysts offer higher specificity, reusability, and operational stability compared to traditional immobilized catalysts, enhancing efficiency in industrial biochemical processes.

Allosteric regulation

Allosteric regulation in enzyme catalysis offers precise, reversible control of enzyme activity through effector molecules binding at specific sites, unlike traditional catalysis which typically lacks this level of regulatory specificity.

Inhibition mechanism

Enzyme catalysis inhibition involves specific interactions at the active site, such as competitive or non-competitive binding, whereas traditional catalysis inhibition typically relies on changes in reaction conditions or deactivation of catalytic surfaces.

Regioselectivity

Enzyme catalysis exhibits superior regioselectivity compared to traditional catalysis due to its highly specific active site that directs substrate binding and reaction position.

Traditional catalysis vs enzyme catalysis Infographic

njnir.com

njnir.com