CO2 utilization transforms captured carbon dioxide into valuable chemicals, fuels, and materials, promoting sustainable resource management and reducing greenhouse gas emissions. This approach enhances carbon circularity by converting CO2 into products like methanol, polymers, and synthetic fuels, contributing to a low-carbon economy. In contrast, CO2 capture focuses primarily on isolating carbon dioxide from industrial emissions to prevent its release into the atmosphere, serving as a critical step for carbon storage or subsequent use.

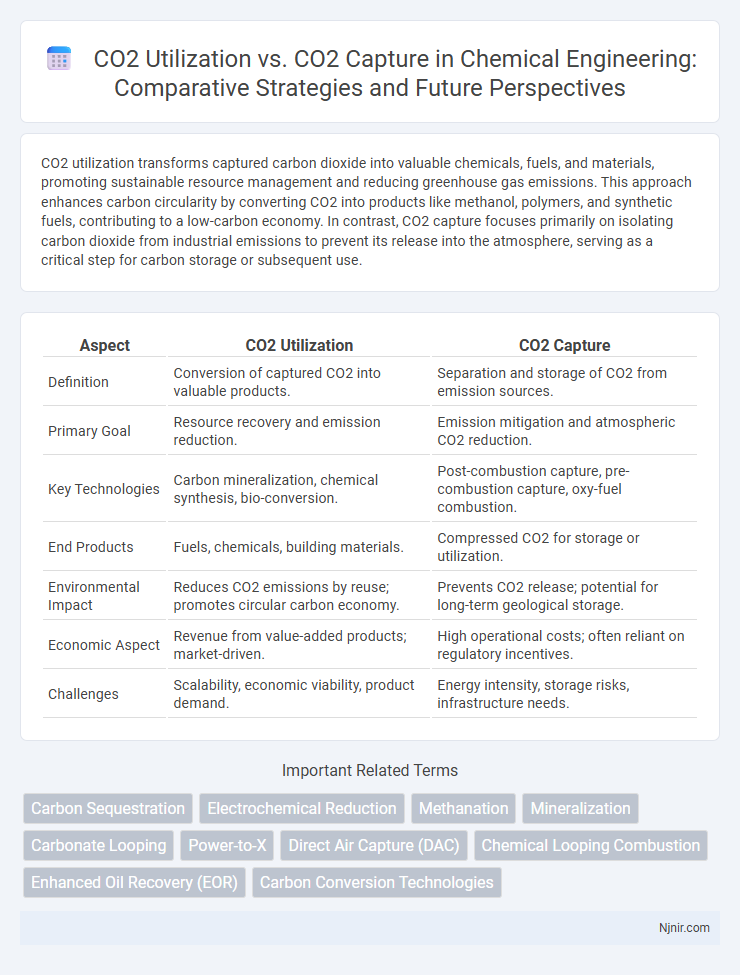

Table of Comparison

| Aspect | CO2 Utilization | CO2 Capture |

|---|---|---|

| Definition | Conversion of captured CO2 into valuable products. | Separation and storage of CO2 from emission sources. |

| Primary Goal | Resource recovery and emission reduction. | Emission mitigation and atmospheric CO2 reduction. |

| Key Technologies | Carbon mineralization, chemical synthesis, bio-conversion. | Post-combustion capture, pre-combustion capture, oxy-fuel combustion. |

| End Products | Fuels, chemicals, building materials. | Compressed CO2 for storage or utilization. |

| Environmental Impact | Reduces CO2 emissions by reuse; promotes circular carbon economy. | Prevents CO2 release; potential for long-term geological storage. |

| Economic Aspect | Revenue from value-added products; market-driven. | High operational costs; often reliant on regulatory incentives. |

| Challenges | Scalability, economic viability, product demand. | Energy intensity, storage risks, infrastructure needs. |

Introduction to CO2 Utilization and Capture

CO2 utilization involves converting captured carbon dioxide into valuable products such as fuels, chemicals, and building materials, thereby reducing greenhouse gas emissions and promoting a circular carbon economy. CO2 capture refers to the process of isolating carbon dioxide from industrial flue gases or the atmosphere to prevent its release into the environment. Both technologies play crucial roles in mitigating climate change, with capture focusing on emission reduction and utilization enabling the transformation of CO2 into commercial assets.

Fundamentals of CO2 Capture Technologies

CO2 capture technologies primarily focus on separating carbon dioxide from industrial emissions through methods like pre-combustion, post-combustion, and oxy-fuel combustion. These processes use solvents, membranes, or adsorption materials to efficiently isolate CO2 for storage or utilization. Understanding the fundamentals of capture efficiency, energy consumption, and scalability is essential for optimizing the integration of CO2 capture in carbon management systems.

Core Principles of CO2 Utilization

CO2 utilization revolves around converting captured carbon dioxide into valuable products such as fuels, chemicals, and materials, emphasizing the transformation and reuse of CO2 to reduce overall emissions. Core principles include the efficient catalytic conversion processes, integration with renewable energy sources to ensure sustainability, and scalability for industrial applications. This approach contrasts with CO2 capture, which primarily focuses on the extraction and sequestration of CO2 from emission sources without necessarily converting it into useful outputs.

Comparative Analysis: Utilization vs Capture

CO2 utilization transforms captured carbon dioxide into valuable products such as fuels, chemicals, and building materials, driving economic incentives and reducing emissions lifecycle. In contrast, CO2 capture primarily focuses on isolating CO2 from industrial sources or the atmosphere to prevent its release, often requiring energy-intensive processes and secure long-term storage solutions. While capture acts as a critical containment strategy for immediate emission reduction, utilization offers a sustainable pathway by closing the carbon loop and enhancing resource efficiency.

Technological Advances in CO2 Capture

Technological advances in CO2 capture have significantly improved the efficiency and cost-effectiveness of isolating carbon dioxide from industrial emissions through methods such as chemical absorption, membrane separation, and cryogenic distillation. Innovations in solvent development, including advanced amines and ionic liquids, enhance CO2 selectivity and reduce energy consumption during the capture process. These breakthroughs enable large-scale deployment of carbon capture systems, providing a crucial foundation for effective carbon utilization technologies and deep decarbonization strategies.

Industrial Applications of CO2 Utilization

CO2 utilization in industrial applications transforms captured carbon dioxide into valuable products such as chemicals, fuels, and building materials, promoting sustainable manufacturing processes. Unlike CO2 capture that primarily aims at preventing emissions, utilization converts CO2 into commercially useful compounds like methanol, polymers, and synthetic hydrocarbons, enabling circular carbon economies. Key sectors benefiting from CO2 utilization include cement production, chemical synthesis, and enhanced oil recovery, which enhance resource efficiency and reduce the carbon footprint of industrial operations.

Environmental Impacts and Sustainability

CO2 utilization converts captured carbon dioxide into valuable products such as fuels, chemicals, and building materials, reducing greenhouse gas emissions and promoting circular carbon economy principles. CO2 capture primarily focuses on extracting carbon dioxide from industrial emissions or the atmosphere, preventing its release but often requires significant energy input and infrastructure. Sustainable CO2 management combines capture with utilization to minimize environmental impacts, enhance resource efficiency, and support carbon neutrality goals.

Economic Considerations in CO2 Management

CO2 utilization transforms captured carbon dioxide into valuable products such as fuels, chemicals, and building materials, potentially generating revenue streams and reducing net emissions costs. In contrast, CO2 capture primarily involves expenses related to technology installation, operation, and storage, often relying on subsidies or carbon pricing mechanisms to justify investments. Economic viability in CO2 management depends on balancing capture costs with utilization market demand, policy incentives, and long-term carbon market stability.

Challenges and Limitations in CO2 Strategies

CO2 utilization faces challenges such as limited technology scalability, high energy requirements for conversion processes, and inconsistent market demand for CO2-derived products, restricting its widespread adoption. CO2 capture is constrained by high operational costs, energy-intensive separation methods, and infrastructure requirements for transportation and storage, which impede large-scale deployment. Both strategies struggle with economic feasibility and regulatory uncertainties, affecting investment and innovation in carbon management solutions.

Future Prospects for CO2 Utilization and Capture

Future prospects for CO2 utilization emphasize transforming captured carbon dioxide into valuable products such as fuels, chemicals, and building materials, leveraging advances in catalysis and carbon conversion technologies. CO2 capture technologies are evolving toward higher efficiency and lower costs through innovations in solvents, membranes, and adsorption materials, enabling large-scale implementation in industrial sectors. Integrating CO2 capture with utilization processes offers a sustainable pathway for reducing greenhouse gas emissions while promoting a circular carbon economy.

Carbon Sequestration

CO2 utilization transforms captured carbon dioxide into valuable products, enhancing carbon sequestration by converting emissions into long-term, stable materials rather than merely storing CO2 underground.

Electrochemical Reduction

Electrochemical reduction of CO2 offers a sustainable approach by directly converting captured CO2 into valuable chemicals and fuels, enhancing CO2 utilization efficiency compared to traditional CO2 capture methods.

Methanation

Methanation efficiently converts captured CO2 into synthetic methane, enabling carbon utilization by recycling emissions into valuable fuel while reducing atmospheric CO2 levels.

Mineralization

Mineralization transforms captured CO2 into stable carbonate minerals, offering a durable solution for CO2 utilization compared to conventional capture methods.

Carbonate Looping

Carbonate looping enhances CO2 capture efficiency by converting captured CO2 into stable carbonates, enabling effective CO2 utilization through mineralization and reducing greenhouse gas emissions.

Power-to-X

Power-to-X technologies convert captured CO2 into valuable synthetic fuels and chemicals, enhancing CO2 utilization efficiency compared to conventional CO2 capture methods alone.

Direct Air Capture (DAC)

Direct Air Capture (DAC) technology focuses on CO2 utilization by extracting atmospheric CO2 for conversion into valuable products, while CO2 capture primarily involves removing emissions from point sources for storage or utilization.

Chemical Looping Combustion

Chemical Looping Combustion offers superior CO2 utilization efficiency by directly converting fuel with inherent CO2 separation, contrasting with conventional CO2 capture methods that primarily focus on post-combustion gas separation.

Enhanced Oil Recovery (EOR)

Enhanced Oil Recovery (EOR) leverages CO2 utilization by injecting captured CO2 into oil reservoirs to increase extraction efficiency while simultaneously storing carbon dioxide underground.

Carbon Conversion Technologies

Carbon conversion technologies enhance CO2 utilization by transforming captured carbon emissions into valuable products such as fuels, chemicals, and building materials, offering a sustainable alternative to conventional CO2 capture methods.

CO2 Utilization vs CO2 Capture Infographic

njnir.com

njnir.com