Computational Fluid Dynamics (CFD) offers a cost-effective, detailed analysis of fluid behavior by solving complex mathematical models, enabling rapid iteration and optimization in chemical engineering processes. Experimental Fluid Dynamics involves physical testing and measurements, providing empirical validation and insights into real-world phenomena that may be challenging to simulate accurately. Combining both approaches enhances the reliability and precision of fluid flow predictions in chemical reactor design and process optimization.

Table of Comparison

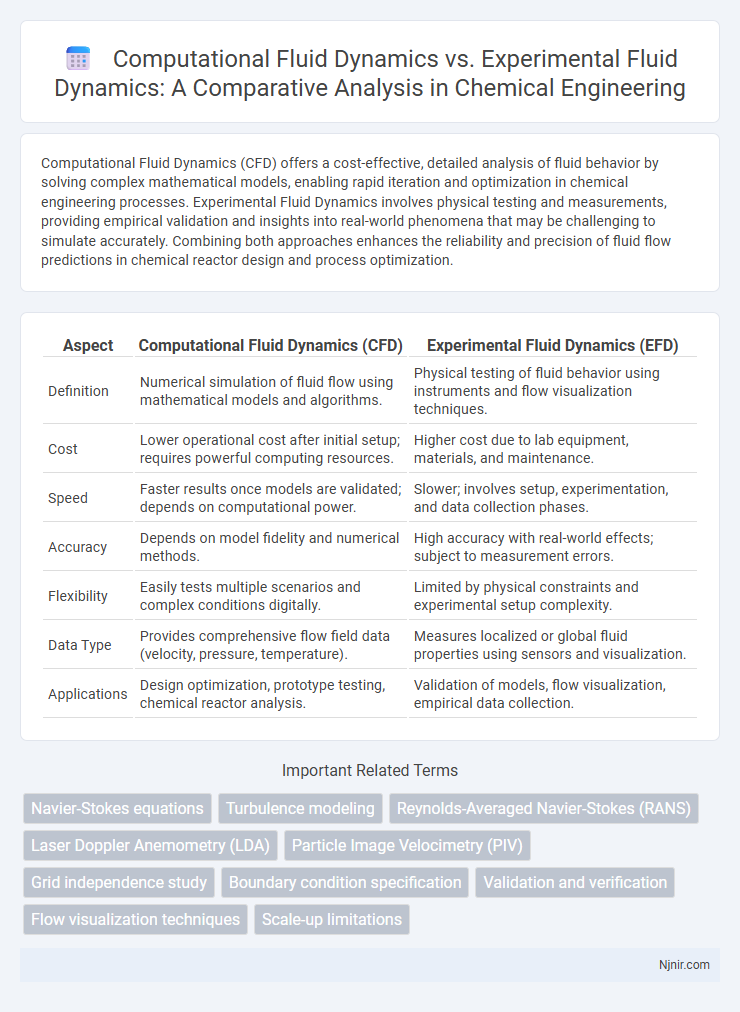

| Aspect | Computational Fluid Dynamics (CFD) | Experimental Fluid Dynamics (EFD) |

|---|---|---|

| Definition | Numerical simulation of fluid flow using mathematical models and algorithms. | Physical testing of fluid behavior using instruments and flow visualization techniques. |

| Cost | Lower operational cost after initial setup; requires powerful computing resources. | Higher cost due to lab equipment, materials, and maintenance. |

| Speed | Faster results once models are validated; depends on computational power. | Slower; involves setup, experimentation, and data collection phases. |

| Accuracy | Depends on model fidelity and numerical methods. | High accuracy with real-world effects; subject to measurement errors. |

| Flexibility | Easily tests multiple scenarios and complex conditions digitally. | Limited by physical constraints and experimental setup complexity. |

| Data Type | Provides comprehensive flow field data (velocity, pressure, temperature). | Measures localized or global fluid properties using sensors and visualization. |

| Applications | Design optimization, prototype testing, chemical reactor analysis. | Validation of models, flow visualization, empirical data collection. |

Introduction to Fluid Dynamics in Chemical Engineering

Computational Fluid Dynamics (CFD) employs numerical methods and algorithms to simulate fluid flow, heat transfer, and chemical reactions in chemical engineering processes, providing detailed insights into complex systems without physical prototypes. Experimental Fluid Dynamics (EFD) relies on physical experiments and measurements to observe real fluid behavior and validate theoretical models, crucial for understanding turbulence, flow patterns, and mixing in reactors. Combining CFD with EFD enhances the design and optimization of chemical processes by integrating predictive simulations with empirical data for accurate fluid dynamics analysis.

Overview of Computational Fluid Dynamics (CFD)

Computational Fluid Dynamics (CFD) utilizes numerical analysis and algorithms to simulate fluid flow and heat transfer, providing detailed insights into complex fluid behaviors in various engineering applications. By solving the Navier-Stokes equations on discretized meshes, CFD enables the visualization of velocity fields, pressure distribution, and turbulence characteristics. This approach offers cost-effective and flexible testing alternatives to traditional Experimental Fluid Dynamics (EFD), enabling rapid prototyping, optimization, and performance prediction in aerospace, automotive, and environmental fluid mechanics.

Fundamentals of Experimental Fluid Dynamics (EFD)

Experimental Fluid Dynamics (EFD) involves physical experiments to observe and measure fluid behavior using techniques like Particle Image Velocimetry (PIV), Laser Doppler Anemometry (LDA), and flow visualization. EFD provides empirical data critical for validating computational models, capturing complex flow phenomena, turbulence, and boundary-layer effects that are difficult to simulate accurately. Fundamental principles in EFD include accurate instrumentation calibration, precise flow control, and repeatability to ensure reliable and meaningful experimental results.

Key Differences Between CFD and EFD

Computational Fluid Dynamics (CFD) utilizes numerical methods and algorithms to simulate fluid flow, offering detailed insights into complex flow behaviors without physical experiments. Experimental Fluid Dynamics (EFD) relies on physical measurements and observations through techniques such as wind tunnels or flow visualization to capture real-world fluid dynamics data. CFD provides flexibility in analyzing multiple scenarios rapidly, while EFD delivers high-fidelity validation data critical for verifying CFD models and understanding phenomena difficult to simulate.

Computational Tools and Software for CFD

Computational Fluid Dynamics (CFD) leverages advanced software like ANSYS Fluent, OpenFOAM, and COMSOL Multiphysics to simulate fluid flow, heat transfer, and chemical reactions with high precision. These computational tools enable detailed analysis of complex geometries and turbulence models that are difficult to replicate experimentally. Experimental Fluid Dynamics relies on physical testing methods such as wind tunnels and particle image velocimetry (PIV), which provide real-world validation but lack the scalability and flexibility offered by CFD software in exploring various scenarios.

Laboratory Techniques in EFD

Laboratory techniques in Experimental Fluid Dynamics (EFD) involve precision instrumentation such as Particle Image Velocimetry (PIV), Laser Doppler Anemometry (LDA), and flow visualization methods to capture real-time fluid behavior with high spatial and temporal resolution. These techniques provide empirical data critical for validating Computational Fluid Dynamics (CFD) models and refining turbulence models, boundary layer characteristics, and flow separation phenomena. Experimental setups often include wind tunnels, water channels, and rotating rigs that replicate complex flow conditions under controlled environments, enabling direct measurement of velocity fields, pressure distributions, and shear stresses.

Accuracy and Validation: CFD vs EFD

Computational Fluid Dynamics (CFD) offers detailed flow visualization and quantitative data, but its accuracy depends heavily on mesh quality, turbulence models, and boundary conditions. Experimental Fluid Dynamics (EFD) provides direct physical measurements, serving as a critical validation benchmark for CFD simulations. Combining CFD predictions with EFD results enhances reliability by identifying model limitations and refining computational methods for improved accuracy.

Cost and Resource Considerations

Computational Fluid Dynamics (CFD) offers significant cost savings over Experimental Fluid Dynamics (EFD) by reducing the need for expensive physical prototypes and wind tunnel testing, with software licenses and high-performance computing resources as primary expenses. EFD requires substantial investment in specialized facilities, skilled personnel, and time-consuming setups, making it less flexible for iterative design modifications. CFD enables faster simulations and scalability, whereas EFD provides high-fidelity validation but at a higher financial and resource burden.

Application Scenarios in Chemical Engineering

Computational Fluid Dynamics (CFD) in chemical engineering enhances reactor design, optimizing flow patterns and heat transfer in processes like catalytic reactors and distillation columns. Experimental Fluid Dynamics (EFD) provides critical validation by measuring velocity fields, turbulence, and mixing in pilot plants or lab-scale equipment using techniques such as Particle Image Velocimetry (PIV) and Laser Doppler Anemometry (LDA). Combining CFD simulations with EFD experiments ensures accurate prediction and effective scaling-up of chemical processes, improving safety and efficiency in operations.

Future Trends in Fluid Dynamics Research

Future trends in Fluid Dynamics research emphasize the integration of Computational Fluid Dynamics (CFD) with Experimental Fluid Dynamics (EFD) techniques to enhance accuracy and predictive capabilities. Advancements in machine learning algorithms and high-performance computing enable more detailed simulations, reducing reliance on costly experiments while improving model validation. Hybrid approaches combining real-time experimental data with CFD models foster adaptive and efficient analysis, accelerating innovation in aerospace, automotive, and renewable energy sectors.

Navier-Stokes equations

Computational Fluid Dynamics solves the Navier-Stokes equations numerically to predict fluid behavior, while Experimental Fluid Dynamics validates these solutions through physical measurements and observations.

Turbulence modeling

Computational Fluid Dynamics (CFD) utilizes numerical turbulence models like Large Eddy Simulation (LES) and Reynolds-Averaged Navier-Stokes (RANS) to predict turbulent flow behavior, while Experimental Fluid Dynamics relies on measurement techniques such as Particle Image Velocimetry (PIV) and Laser Doppler Anemometry (LDA) to capture turbulence characteristics directly in physical flow fields.

Reynolds-Averaged Navier-Stokes (RANS)

Reynolds-Averaged Navier-Stokes (RANS) models in Computational Fluid Dynamics (CFD) provide efficient turbulence approximations crucial for simulating time-averaged flow fields, whereas Experimental Fluid Dynamics (EFD) offers empirical validation through precise physical measurements of fluid behavior.

Laser Doppler Anemometry (LDA)

Laser Doppler Anemometry (LDA) provides high-precision velocity measurements that validate Computational Fluid Dynamics (CFD) simulations by capturing detailed flow characteristics unattainable through purely numerical methods.

Particle Image Velocimetry (PIV)

Particle Image Velocimetry (PIV) in Experimental Fluid Dynamics provides high-resolution velocity field measurements that validate and complement Computational Fluid Dynamics simulations by capturing real-time particle movement within fluid flows.

Grid independence study

Grid independence studies in Computational Fluid Dynamics ensure solution accuracy by systematically refining mesh resolution, whereas Experimental Fluid Dynamics relies on physical measurements without mesh discretization, highlighting the importance of numerical grid validation for CFD results.

Boundary condition specification

Computational Fluid Dynamics requires precise mathematical boundary condition specifications for accurate simulation of flow behaviors, while Experimental Fluid Dynamics relies on physical measurement and control of boundary conditions to validate real-world fluid interactions.

Validation and verification

Computational Fluid Dynamics (CFD) relies on rigorous validation against experimental fluid dynamics (EFD) data and systematic verification of numerical models to ensure accurate simulation of fluid behavior.

Flow visualization techniques

Computational Fluid Dynamics employs numerical simulations using methods like finite volume and finite element to generate detailed flow visualizations, while Experimental Fluid Dynamics utilizes physical techniques such as particle image velocimetry and laser Doppler anemometry to capture real-time flow patterns and validate computational models.

Scale-up limitations

Computational Fluid Dynamics faces scale-up limitations due to model simplifications and numerical approximations, whereas Experimental Fluid Dynamics encounters challenges in replicating large-scale flow conditions and precise measurement accuracy.

Computational Fluid Dynamics vs Experimental Fluid Dynamics Infographic

njnir.com

njnir.com