Smart materials offer adaptive properties such as self-healing, shape memory, and responsiveness to environmental changes, enhancing chemical engineering applications with improved efficiency and durability. Conventional materials lack these dynamic features, often requiring external inputs or replacements to maintain functionality. Incorporating smart materials reduces maintenance costs and extends the lifespan of chemical processes by providing real-time responsiveness and environmental adaptability.

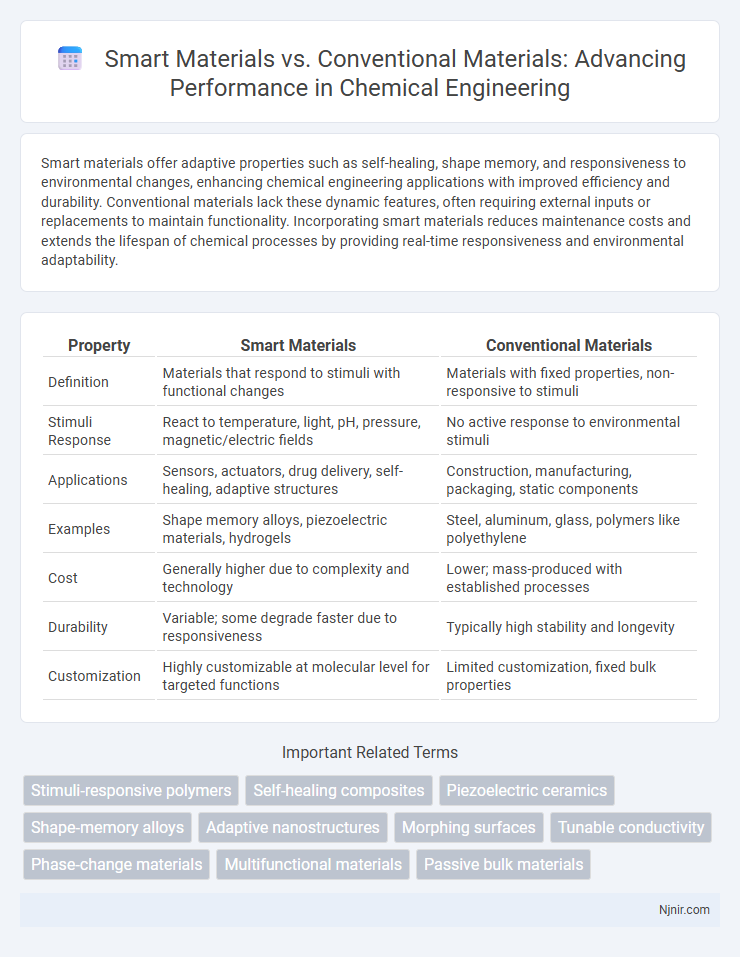

Table of Comparison

| Property | Smart Materials | Conventional Materials |

|---|---|---|

| Definition | Materials that respond to stimuli with functional changes | Materials with fixed properties, non-responsive to stimuli |

| Stimuli Response | React to temperature, light, pH, pressure, magnetic/electric fields | No active response to environmental stimuli |

| Applications | Sensors, actuators, drug delivery, self-healing, adaptive structures | Construction, manufacturing, packaging, static components |

| Examples | Shape memory alloys, piezoelectric materials, hydrogels | Steel, aluminum, glass, polymers like polyethylene |

| Cost | Generally higher due to complexity and technology | Lower; mass-produced with established processes |

| Durability | Variable; some degrade faster due to responsiveness | Typically high stability and longevity |

| Customization | Highly customizable at molecular level for targeted functions | Limited customization, fixed bulk properties |

Introduction to Smart vs Conventional Materials in Chemical Engineering

Smart materials in chemical engineering exhibit responsive properties that adapt to environmental stimuli such as temperature, pH, or stress, enabling enhanced process control and efficiency. Conventional materials, by contrast, maintain fixed characteristics without dynamic responses, limiting adaptability in complex chemical processes. The integration of smart materials facilitates innovation in sensors, actuators, and drug delivery systems, transforming traditional chemical engineering applications.

Fundamental Properties and Differences

Smart materials exhibit unique responsive properties such as shape memory, self-healing, and sensory capabilities, whereas conventional materials primarily offer static mechanical and thermal characteristics. Fundamental differences lie in smart materials' ability to adapt dynamically to environmental stimuli such as temperature, stress, and electric fields, contrasting with conventional materials that maintain consistent behavior under similar conditions. Key examples include piezoelectric ceramics, thermochromic polymers, and shape memory alloys, which demonstrate multifunctionality absent in traditional metals, ceramics, and polymers.

Mechanisms of Smart Material Functionality

Smart materials operate through mechanisms such as phase transformations, shape memory effects, and piezoelectric responses, enabling adaptive behavior under environmental stimuli like temperature, stress, or electric fields. Conventional materials lack this intrinsic ability to sense and respond dynamically, relying instead on fixed properties imposed during manufacturing. The integration of sensing and actuation within smart materials enhances applications in aerospace, robotics, and biomedical devices by providing real-time functionality adjustments.

Performance in Industrial Processes

Smart materials exhibit superior performance in industrial processes through their ability to adapt to environmental changes, enhancing efficiency and reducing waste. Unlike conventional materials, smart materials respond to stimuli such as temperature, pressure, or electric fields, enabling real-time adjustments and improved durability. This adaptability leads to optimized energy consumption and prolonged equipment lifespan in manufacturing applications.

Applications in Chemical Engineering

Smart materials such as shape memory alloys, piezoelectric materials, and stimuli-responsive polymers enable advanced applications in chemical engineering like controlled drug delivery, real-time structural health monitoring of reactors, and adaptive separation processes. Conventional materials like stainless steel and carbon fibers provide robust and cost-effective solutions for piping, reactors, and storage tanks but lack the dynamic responsiveness of smart materials. The integration of smart materials enhances process efficiency, reduces downtime, and enables precise control in chemical reactors and sensor systems compared to traditional materials.

Environmental Impact and Sustainability

Smart materials reduce environmental impact by adapting to changing conditions, which enhances energy efficiency and minimizes resource consumption compared to conventional materials. These materials often incorporate self-healing, recyclability, and biodegradability features, promoting sustainability and reducing waste in construction and manufacturing. In contrast, conventional materials typically involve higher carbon footprints and limited lifecycle adaptability, leading to increased environmental degradation.

Cost-Effectiveness and Economic Considerations

Smart materials often entail higher initial costs compared to conventional materials due to advanced technology integration and specialized manufacturing processes. However, their ability to self-heal, adapt, or improve performance over time can lead to long-term economic benefits by reducing maintenance, downtime, and replacement expenses. When evaluating cost-effectiveness, smart materials may offer superior value in applications requiring durability and efficiency despite the higher upfront investment.

Integration Challenges and Solutions

Smart materials face integration challenges such as compatibility with existing manufacturing processes, durability under variable conditions, and complex control systems requirements. Solutions include developing hybrid fabrication techniques, enhancing material interfaces through nanoscale engineering, and employing advanced sensor networks for real-time monitoring and adaptive control. Addressing these factors accelerates the practical adoption of smart materials in industries like aerospace, automotive, and healthcare.

Future Trends in Material Innovation

Smart materials increasingly incorporate sensors and actuators to enable real-time response and adaptation, revolutionizing sectors like aerospace, healthcare, and construction. Advances in nanotechnology and artificial intelligence integration drive the development of multifunctional materials with self-healing, shape-memory, and energy-harvesting capabilities. Conventional materials face transformation as hybrid composites and bio-inspired designs emerge, pushing boundaries toward sustainability and enhanced performance in future applications.

Conclusion and Outlook for Engineering Materials

Smart materials offer adaptive properties such as self-healing, shape memory, and responsiveness to environmental stimuli, setting them apart from conventional materials with fixed characteristics. The integration of smart materials into engineering designs promises enhanced performance, durability, and sustainability in sectors like aerospace, civil infrastructure, and biomedical devices. Future advancements in nanotechnology and material science will likely drive the wider adoption and functionality of smart materials, fundamentally transforming engineering practices and material selection criteria.

Stimuli-responsive polymers

Stimuli-responsive polymers, a key subset of smart materials, dynamically alter their physical or chemical properties in response to external stimuli such as temperature, pH, or light, offering superior adaptability and functionality compared to conventional materials.

Self-healing composites

Self-healing composites in smart materials autonomously repair damage using embedded microcapsules or vascular networks, significantly enhancing durability and lifespan compared to conventional materials.

Piezoelectric ceramics

Piezoelectric ceramics in smart materials generate electric charge under mechanical stress, enabling advanced sensing and actuation beyond the static properties of conventional materials.

Shape-memory alloys

Shape-memory alloys, a type of smart material, uniquely revert to their original shape after deformation through thermal activation, offering superior performance and adaptability compared to conventional materials in aerospace, medical devices, and robotics.

Adaptive nanostructures

Adaptive nanostructures in smart materials enable dynamic responses to environmental stimuli, vastly outperforming conventional materials in functionality and efficiency.

Morphing surfaces

Morphing surfaces in smart materials enable real-time shape adaptation through embedded sensors and actuators, providing superior flexibility and functionality compared to rigid conventional materials.

Tunable conductivity

Smart materials with tunable conductivity enable real-time adjustment of electrical properties, outperforming conventional materials with fixed conductivity in adaptive electronic applications.

Phase-change materials

Phase-change materials in smart technologies enable reversible thermal energy storage and efficient temperature regulation, outperforming conventional materials with static properties.

Multifunctional materials

Multifunctional smart materials, integrating sensing, actuating, and self-healing capabilities, outperform conventional materials by enhancing structural efficiency and enabling adaptive responses in aerospace and biomedical applications.

Passive bulk materials

Passive bulk smart materials exhibit enhanced responsiveness to environmental stimuli compared to conventional passive bulk materials, enabling improved durability and functionality in structural applications.

Smart Materials vs Conventional Materials Infographic

njnir.com

njnir.com