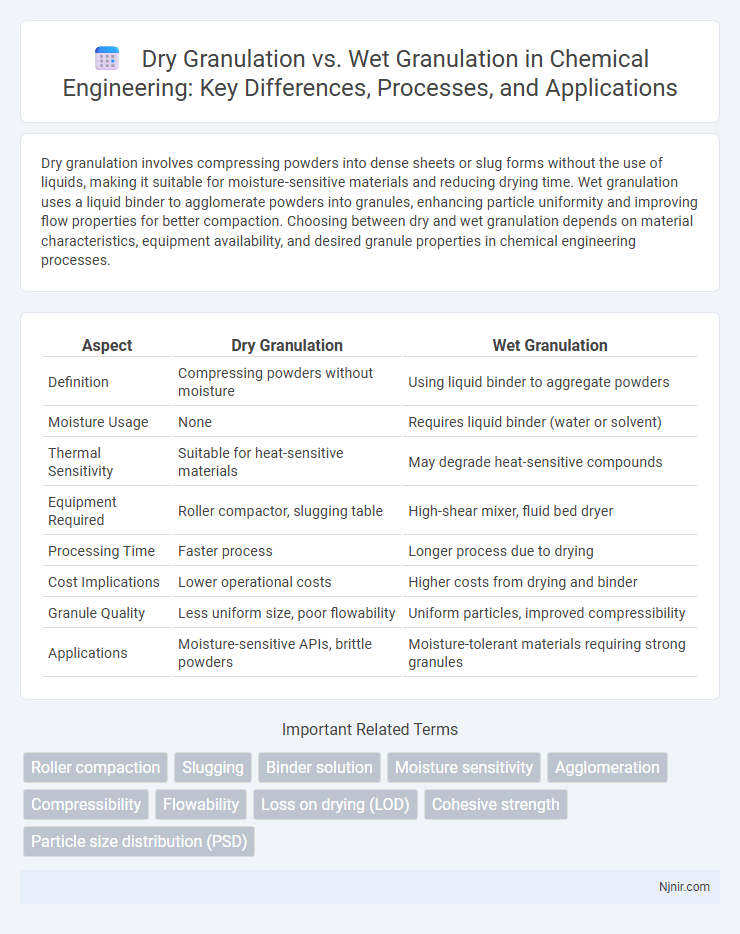

Dry granulation involves compressing powders into dense sheets or slug forms without the use of liquids, making it suitable for moisture-sensitive materials and reducing drying time. Wet granulation uses a liquid binder to agglomerate powders into granules, enhancing particle uniformity and improving flow properties for better compaction. Choosing between dry and wet granulation depends on material characteristics, equipment availability, and desired granule properties in chemical engineering processes.

Table of Comparison

| Aspect | Dry Granulation | Wet Granulation |

|---|---|---|

| Definition | Compressing powders without moisture | Using liquid binder to aggregate powders |

| Moisture Usage | None | Requires liquid binder (water or solvent) |

| Thermal Sensitivity | Suitable for heat-sensitive materials | May degrade heat-sensitive compounds |

| Equipment Required | Roller compactor, slugging table | High-shear mixer, fluid bed dryer |

| Processing Time | Faster process | Longer process due to drying |

| Cost Implications | Lower operational costs | Higher costs from drying and binder |

| Granule Quality | Less uniform size, poor flowability | Uniform particles, improved compressibility |

| Applications | Moisture-sensitive APIs, brittle powders | Moisture-tolerant materials requiring strong granules |

Introduction to Granulation Techniques

Dry granulation involves compacting powder into dense sheets or slugs without using a liquid binder, making it ideal for moisture-sensitive materials. Wet granulation uses a liquid solution to agglomerate powders, enhancing flowability and compressibility for tablet formulation. Selecting between dry and wet granulation depends on factors like material properties, moisture sensitivity, and desired granule characteristics.

Fundamental Principles of Dry Granulation

Dry granulation involves compacting powders without using liquid binders, relying on mechanical pressure to form granules through slugging or roller compaction. This method preserves heat-sensitive ingredients and improves flowability and compressibility by increasing particle size and density. Key parameters include the applied pressure, powder characteristics, and compression speed, which directly affect granule strength and uniformity.

Core Concepts of Wet Granulation

Wet granulation involves the agglomeration of powder particles using a liquid binder, which enhances particle adhesion and improves the flowability and compressibility of the material. The process typically includes wet massing, screening, and drying, resulting in granules with uniform size distribution and reduced dust formation. This technique is preferred for formulations sensitive to segregation or requiring enhanced content uniformity and mechanical strength.

Equipment Used in Dry Granulation

Dry granulation uses equipment such as roller compactors and slugging machines to compress powders into granules without the use of liquids, preserving moisture-sensitive ingredients. Roller compactors consist of two counter-rotating rollers that apply pressure to form ribbons, which are then milled into granules. This equipment offers advantages in pharmaceuticals and food industries by enabling granule formation while avoiding drying steps required in wet granulation processes.

Equipment Used in Wet Granulation

Wet granulation primarily utilizes high-shear mixers and fluid bed granulators, which enable efficient agglomeration through controlled liquid addition and mechanical agitation. High-shear mixers combine powders and binder solutions to form dense granules, while fluid bed granulators dry and cure wet granules, improving particle uniformity and flowability. These equipment types are essential in pharmaceutical and food industries for producing consistent, robust granules compared to dry granulation methods like slugging or roller compaction.

Process Parameters and Control

Dry granulation involves compacting powders without the use of liquid binders, relying heavily on compression force and roll speed as critical process parameters to ensure consistent granule size and density. In wet granulation, parameters such as binder concentration, liquid addition rate, and mixing time are meticulously controlled to achieve optimal granule strength and moisture content. Process monitoring techniques like torque measurement and moisture analysis are essential in both methods to maintain product uniformity and performance in pharmaceutical manufacturing.

Granule Properties: Comparison and Evaluation

Dry granulation produces granules with higher density and better flowability, ideal for moisture-sensitive drugs, while wet granulation results in more uniform particle size distribution and enhanced compressibility. Wet granulated granules typically exhibit improved dissolution rates due to better binder distribution, whereas dry granulated granules may have higher friability and less uniform strength. Granule porosity is lower in dry granulation, affecting tablet hardness and disintegration times differently compared to the more porous granules from wet granulation processes.

Advantages and Limitations of Dry Granulation

Dry granulation offers advantages such as eliminating the need for solvents, reducing drying time, and being suitable for moisture-sensitive and heat-labile materials, which enhances efficiency and cost-effectiveness in pharmaceutical manufacturing. Limitations include lower particle density and potential issues with compressibility, leading to less uniform granule size and possible challenges in tablet hardness and dissolution rates. This method is preferred for formulations where solvent use is impractical or undesirable but may require additional optimization to meet product specifications.

Advantages and Limitations of Wet Granulation

Wet granulation offers enhanced powder cohesiveness and improved flow properties, making it ideal for producing uniform particle size distribution and consistent tablet weight in pharmaceutical manufacturing. This process facilitates better compression characteristics and allows for incorporation of active pharmaceutical ingredients that are sensitive to dust generation. Limitations include the need for drying time and energy consumption, potential drug degradation due to moisture and heat exposure, and increased complexity in equipment and process control compared to dry granulation.

Industrial Applications and Case Studies

Dry granulation is favored in pharmaceutical manufacturing for moisture-sensitive drugs and heat-labile compounds, ensuring product stability without solvent use. Wet granulation dominates in producing tablets requiring enhanced compressibility and homogeneity, commonly applied in high-volume antibiotic and analgesic formulations. Case studies demonstrate dry granulation's efficiency in low-moisture environments, while wet granulation achieves superior bioavailability in complex multilayer tablets.

Roller compaction

Roller compaction in dry granulation produces dense granules by compressing powders under high pressure without using liquids, resulting in improved flowability and reduced drying time compared to wet granulation that involves moisture and subsequent drying steps.

Slugging

Dry granulation through slugging compacts powders into dense slugs without using liquid binders, enabling better handling of moisture-sensitive materials compared to wet granulation.

Binder solution

Dry granulation eliminates the need for a binder solution by compacting powders under pressure, whereas wet granulation relies on a liquid binder solution to agglomerate particles before drying.

Moisture sensitivity

Dry granulation is ideal for moisture-sensitive materials as it avoids liquid binders, whereas wet granulation involves adding liquids that can compromise moisture-sensitive drug stability.

Agglomeration

Dry granulation uses compaction or roller compaction to achieve particle agglomeration without liquid, while wet granulation relies on a liquid binder to form strong, cohesive agglomerates.

Compressibility

Dry granulation enhances compressibility by producing denser granules with improved binding properties, whereas wet granulation typically yields granules with higher porosity and variable compressibility due to moisture content.

Flowability

Dry granulation improves flowability by producing denser, more uniform granules with enhanced compressibility compared to wet granulation, which may result in variable flow properties due to moisture content.

Loss on drying (LOD)

Dry granulation consistently results in a lower Loss on Drying (LOD) compared to wet granulation due to the absence of moisture during the compaction process.

Cohesive strength

Dry granulation typically results in lower cohesive strength compared to wet granulation due to the absence of liquid binders that enhance particle adhesion.

Particle size distribution (PSD)

Dry granulation produces a broader particle size distribution with larger aggregates compared to wet granulation, which yields more uniform and finer particles due to liquid binder effects on particle agglomeration.

Dry granulation vs Wet granulation Infographic

njnir.com

njnir.com