Computational Fluid Dynamics (CFD) offers detailed insights into flow patterns and reaction kinetics that can be challenging to capture experimentally in chemical engineering processes. Experimental data provide essential validation for CFD models, ensuring their accuracy and reliability under real-world conditions. Combining CFD simulations with empirical measurements enhances process optimization and scale-up by bridging theoretical predictions with practical outcomes.

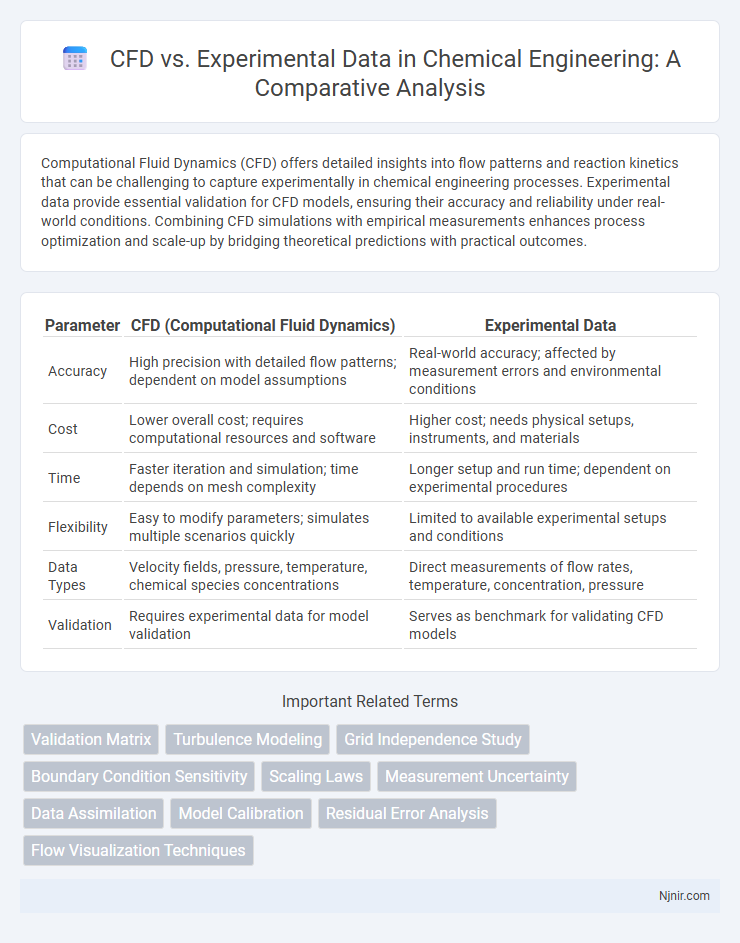

Table of Comparison

| Parameter | CFD (Computational Fluid Dynamics) | Experimental Data |

|---|---|---|

| Accuracy | High precision with detailed flow patterns; dependent on model assumptions | Real-world accuracy; affected by measurement errors and environmental conditions |

| Cost | Lower overall cost; requires computational resources and software | Higher cost; needs physical setups, instruments, and materials |

| Time | Faster iteration and simulation; time depends on mesh complexity | Longer setup and run time; dependent on experimental procedures |

| Flexibility | Easy to modify parameters; simulates multiple scenarios quickly | Limited to available experimental setups and conditions |

| Data Types | Velocity fields, pressure, temperature, chemical species concentrations | Direct measurements of flow rates, temperature, concentration, pressure |

| Validation | Requires experimental data for model validation | Serves as benchmark for validating CFD models |

Introduction to Computational Fluid Dynamics (CFD)

Computational Fluid Dynamics (CFD) utilizes numerical methods and algorithms to analyze and solve problems involving fluid flows by simulating fluid behavior digitally. CFD provides detailed insights into velocity, pressure, and temperature fields, enabling engineers to predict fluid interactions accurately without physical prototypes. Comparing CFD results with experimental data ensures model validation, enhancing the reliability of simulations in design and optimization processes.

Importance of Experimental Data in Chemical Engineering

Experimental data provides the essential benchmark for validating Computational Fluid Dynamics (CFD) simulations in chemical engineering by ensuring accuracy and reliability. Accurate measurements of flow patterns, temperature distribution, and phase interactions obtained through experiments enable the calibration of CFD models to reflect real-world behavior. The integration of experimental insights enhances process optimization, safety assessments, and design improvements in chemical reactors and equipment.

Methodologies: CFD Simulation vs Experimental Techniques

CFD simulation employs numerical methods and algorithms to solve and analyze fluid flow, heat transfer, and related phenomena by discretizing governing equations such as Navier-Stokes, enabling detailed visualization of flow fields and parametric studies. Experimental techniques involve physical testing using wind tunnels, water channels, or flow rigs equipped with sensors like pressure transducers, hot-wire anemometry, or Particle Image Velocimetry (PIV) to directly measure velocity, pressure, and turbulence characteristics. The methodologies differ fundamentally as CFD relies on computational grids and turbulence models requiring validation, whereas experimental approaches provide empirical data with potential measurement uncertainties influenced by instrumentation and environmental conditions.

Accuracy and Reliability: Strengths and Limitations

Computational Fluid Dynamics (CFD) offers detailed flow field predictions with high spatial and temporal resolution, enabling the analysis of complex fluid behaviors that are difficult to measure experimentally. Experimental data provides real-world accuracy for validating CFD models, but measurements can be limited by sensor precision, environmental variability, and accessibility to flow regions. Both methods have inherent strengths and limitations; CFD relies on turbulence models and numerical approximations that may introduce errors, whereas experimental data can suffer from measurement uncertainties and scale effects, making combined use essential for reliable fluid dynamics analysis.

Validation and Verification of CFD Models

Validation and verification (V&V) of CFD models are crucial to ensure their accuracy and reliability by comparing simulation results against experimental data. Verification focuses on confirming the mathematical correctness and numerical accuracy of the CFD code, while validation assesses how well the model predictions replicate physical experiments. Precise V&V processes help identify model limitations, improve turbulence models, and enhance boundary condition settings for more accurate fluid flow simulations.

Cost and Time Efficiency Analysis

Computational Fluid Dynamics (CFD) significantly reduces costs by minimizing the need for physical prototypes and extensive laboratory setups, which are expensive and resource-intensive. Time efficiency is greatly enhanced as CFD simulations allow rapid iterations and adjustments without waiting for material fabrication or experimental delays. However, experimental data remains critical for validating CFD models, ensuring accuracy despite its higher cost and longer time requirements.

Case Studies: CFD Predictions vs Experimental Observations

Case studies comparing CFD predictions with experimental observations reveal strong correlations in flow behavior, pressure distribution, and thermal management across various engineering applications. Discrepancies often arise due to mesh resolution, turbulence modeling limitations, and boundary condition assumptions, highlighting the importance of validation efforts. These comparative analyses enhance model accuracy, informing design optimization and reducing reliance on costly physical testing.

Common Challenges in Data Comparison

Discrepancies between CFD simulations and experimental data commonly arise from differences in boundary conditions, mesh resolution, and turbulence modeling accuracy. Measurement uncertainties and sensor limitations in experiments often introduce errors that complicate direct comparisons with CFD results. Consistent validation requires aligning input parameters, refining numerical schemes, and accounting for experimental variability to reduce deviations.

Integration of CFD and Experimental Approaches

Integrating CFD and experimental data enhances the reliability of fluid dynamics analysis by combining precise computational predictions with real-world measurements. This hybrid approach enables validation and calibration of CFD models, reducing uncertainties and improving accuracy in complex flow simulations. Leveraging high-fidelity experimental data alongside advanced CFD techniques accelerates innovation in aerospace, automotive, and environmental engineering applications.

Future Trends in Chemical Engineering: CFD and Experiments

Future trends in chemical engineering emphasize the integration of Computational Fluid Dynamics (CFD) with experimental data to enhance model accuracy and predictive capabilities. Hybrid approaches leveraging machine learning algorithms optimize the calibration of CFD models using real-time experimental results, enabling efficient scale-up processes. Advancements in high-fidelity simulations combined with precise experimental techniques drive innovation in reactor design, process optimization, and environmental impact assessments.

Validation Matrix

Validation matrix comparing CFD simulations and experimental data quantifies discrepancies using metrics like RMSE, correlation coefficients, and percentage errors to assess model accuracy.

Turbulence Modeling

CFD turbulence modeling accuracy critically depends on selecting appropriate models like RANS, LES, or DES to closely match experimental data in predicting complex flow behaviors.

Grid Independence Study

Grid independence study in CFD ensures accurate simulation results by systematically refining the mesh until changes in flow variables between successive grids become negligible, aligning closely with experimental data for validation.

Boundary Condition Sensitivity

Boundary condition sensitivity in CFD significantly influences the accuracy of simulations when compared to experimental data, highlighting the need for precise boundary parameter definitions to achieve reliable predictive performance.

Scaling Laws

Scaling laws in CFD enhance predictive accuracy by correlating dimensionless parameters with experimental data across different flow regimes.

Measurement Uncertainty

Measurement uncertainty significantly influences the accuracy of experimental data, often causing discrepancies when compared to CFD simulations.

Data Assimilation

Data assimilation integrates CFD simulations with experimental data to enhance model accuracy and reduce predictive uncertainty in fluid dynamics analysis.

Model Calibration

Model calibration aligns CFD simulations with experimental data by systematically adjusting model parameters to enhance prediction accuracy and validate fluid flow behavior.

Residual Error Analysis

Residual error analysis quantifies discrepancies between CFD simulations and experimental data, identifying model inaccuracies and guiding improvements in flow prediction accuracy.

Flow Visualization Techniques

Flow visualization techniques in CFD and experimental data reveal critical differences in fluid behavior patterns, with particle image velocimetry (PIV) and laser Doppler velocimetry (LDV) offering experimental insights that validate and refine computational flow simulations.

CFD vs Experimental Data Infographic

njnir.com

njnir.com