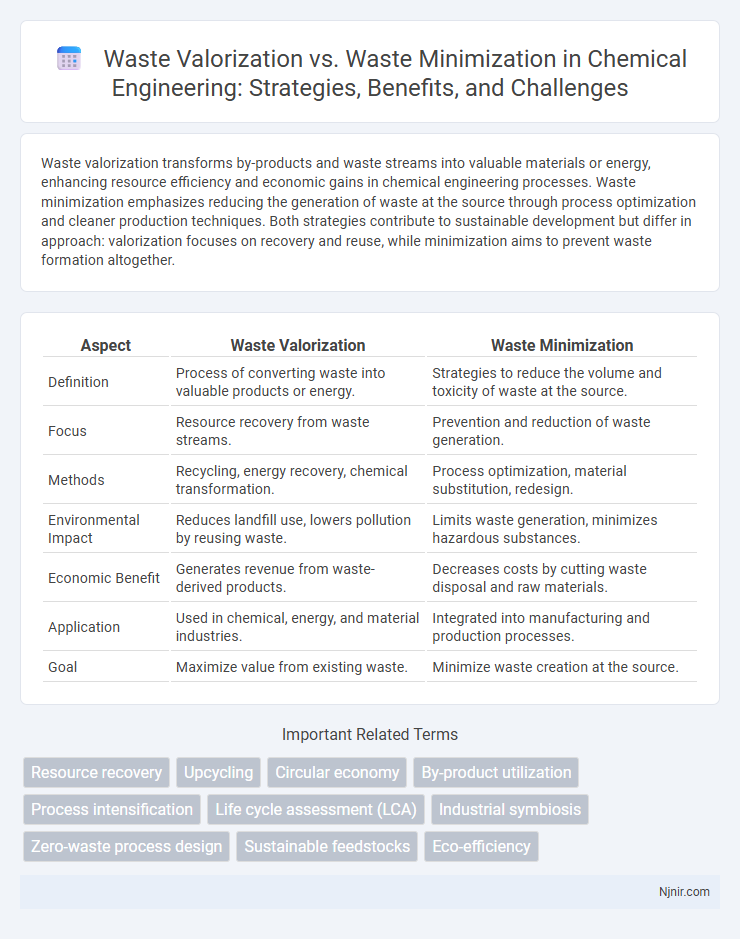

Waste valorization transforms by-products and waste streams into valuable materials or energy, enhancing resource efficiency and economic gains in chemical engineering processes. Waste minimization emphasizes reducing the generation of waste at the source through process optimization and cleaner production techniques. Both strategies contribute to sustainable development but differ in approach: valorization focuses on recovery and reuse, while minimization aims to prevent waste formation altogether.

Table of Comparison

| Aspect | Waste Valorization | Waste Minimization |

|---|---|---|

| Definition | Process of converting waste into valuable products or energy. | Strategies to reduce the volume and toxicity of waste at the source. |

| Focus | Resource recovery from waste streams. | Prevention and reduction of waste generation. |

| Methods | Recycling, energy recovery, chemical transformation. | Process optimization, material substitution, redesign. |

| Environmental Impact | Reduces landfill use, lowers pollution by reusing waste. | Limits waste generation, minimizes hazardous substances. |

| Economic Benefit | Generates revenue from waste-derived products. | Decreases costs by cutting waste disposal and raw materials. |

| Application | Used in chemical, energy, and material industries. | Integrated into manufacturing and production processes. |

| Goal | Maximize value from existing waste. | Minimize waste creation at the source. |

Introduction to Waste Management in Chemical Engineering

Waste valorization enhances chemical engineering waste management by converting by-products into valuable resources, promoting sustainability and resource efficiency. Waste minimization focuses on reducing waste generation at its source through process optimization and innovative design, lowering environmental impact and operational costs. Integrating both strategies advances overall waste management, aligning chemical processes with environmental regulations and circular economy principles.

Defining Waste Valorization

Waste valorization refers to the process of converting waste materials into valuable products such as energy, chemicals, or raw materials, enhancing resource efficiency and reducing environmental impact. It involves innovative technologies like anaerobic digestion, pyrolysis, and recycling to recover useful components from waste streams. Unlike waste minimization, which aims to reduce waste generation at the source, waste valorization focuses on transforming existing waste into economically beneficial outputs.

Understanding Waste Minimization

Waste minimization focuses on reducing the volume and toxicity of waste generated at the source through process modifications, material substitutions, and efficient resource use. It emphasizes prevention strategies such as redesigning products and optimizing manufacturing techniques to decrease raw material consumption and waste output. This proactive approach contrasts with waste valorization, which primarily deals with treating and converting waste into useful products after generation.

Key Differences Between Waste Valorization and Minimization

Waste valorization involves converting waste materials into valuable products, such as energy, chemicals, or raw materials, enhancing resource recovery and economic benefits. Waste minimization focuses on reducing the generation of waste at the source through process optimization, material substitution, and efficient resource use, aiming to decrease environmental impact and disposal costs. Key differences include valorization's emphasis on transformation and reutilization of existing waste streams, while minimization targets prevention and reduction of waste creation.

Technological Approaches in Waste Valorization

Technological approaches in waste valorization focus on converting waste materials into valuable resources through processes such as pyrolysis, gasification, and anaerobic digestion, enhancing resource recovery and energy generation. Advanced biotechnological methods utilize microbes to transform organic waste into biofuels, bioplastics, and fertilizers, promoting circular economy principles. These technologies contrast with waste minimization strategies, which prioritize reducing waste generation at the source rather than converting waste into new products.

Process Optimization for Waste Minimization

Process optimization for waste minimization focuses on enhancing manufacturing techniques to reduce raw material usage, energy consumption, and by-product generation at the source. Implementing lean production methods, real-time monitoring, and efficient resource allocation leads to lower operational costs and decreased environmental impact. Unlike waste valorization, which transforms existing waste into valuable products, process optimization aims to prevent waste creation, promoting sustainability and regulatory compliance.

Environmental Impact and Sustainability

Waste valorization enhances environmental sustainability by converting waste materials into valuable resources, thereby reducing landfill use and lowering greenhouse gas emissions. Waste minimization focuses on reducing the generation of waste at the source, which decreases resource consumption and minimizes pollution throughout the production cycle. Both strategies are crucial for sustainable waste management, with valorization promoting circular economy principles and minimization emphasizing prevention and efficiency.

Economic Benefits and Challenges

Waste valorization transforms waste materials into valuable products, generating new revenue streams and reducing disposal costs, which boosts economic growth and promotes sustainable resource management. Waste minimization lowers production expenses by reducing raw material use and waste generation, enhancing efficiency and cutting operational costs, but may require initial investments in cleaner technologies. Both approaches face challenges such as market acceptance, technological complexity, and regulatory compliance, impacting their economic viability and long-term profitability.

Regulatory and Policy Considerations

Waste valorization policies prioritize converting waste into valuable resources, supported by incentives like tax credits and grants that encourage recycling and energy recovery technologies. Waste minimization regulations emphasize reducing waste generation at the source through strict limits on hazardous materials, product design standards, and mandatory reporting requirements. Regulatory frameworks increasingly integrate both approaches to promote sustainable waste management, aligning with circular economy goals and reducing environmental impact.

Future Trends in Waste Management Strategies

Future trends in waste management strategies emphasize integrating waste valorization techniques such as bioenergy recovery and material recycling to transform waste into valuable resources, reducing landfill dependency. Advancements in smart sorting technologies and circular economy models support enhanced waste minimization by preventing waste generation through design innovation and sustainable consumption patterns. Artificial intelligence and IoT-driven monitoring systems enable real-time waste tracking, optimizing both valorization processes and minimization efforts for improved environmental and economic outcomes.

Resource recovery

Waste valorization enhances resource recovery by transforming waste into valuable products, whereas waste minimization focuses on reducing waste generation to limit resource consumption.

Upcycling

Upcycling transforms waste into higher-value products, enhancing waste valorization by creating valuable resources, whereas waste minimization focuses on reducing the overall generation of waste at the source.

Circular economy

Waste valorization in the circular economy enhances resource efficiency by converting waste into valuable products, while waste minimization aims to reduce waste generation at the source to promote sustainable consumption and production.

By-product utilization

By-product utilization in waste valorization transforms industrial residues into valuable products, significantly enhancing resource efficiency compared to waste minimization, which primarily focuses on reducing waste generation at the source.

Process intensification

Process intensification in waste valorization enhances resource recovery by transforming waste into valuable products, while process intensification in waste minimization optimizes operational efficiency to reduce waste generation and environmental impact.

Life cycle assessment (LCA)

Waste valorization enhances resource recovery and environmental benefits through Life Cycle Assessment (LCA) by optimizing material reuse, whereas waste minimization focuses on reducing waste generation at the source to lower overall environmental impacts.

Industrial symbiosis

Industrial symbiosis enhances waste valorization by transforming by-products into valuable resources, significantly reducing waste generation and surpassing traditional waste minimization methods in sustainability efficiency.

Zero-waste process design

Zero-waste process design prioritizes waste valorization by transforming all waste streams into valuable resources, whereas waste minimization focuses on reducing waste generation at the source to achieve sustainable, circular manufacturing.

Sustainable feedstocks

Sustainable feedstocks in waste valorization transform organic residues into valuable products, enhancing resource efficiency compared to waste minimization's focus on reducing waste generation at the source.

Eco-efficiency

Waste valorization enhances eco-efficiency by converting waste into valuable resources, whereas waste minimization reduces environmental impact by limiting waste generation at the source.

Waste valorization vs Waste minimization Infographic

njnir.com

njnir.com