Direct air capture (DAC) extracts CO2 directly from ambient air, offering flexibility in location but facing challenges due to low CO2 concentration. Flue gas capture targets concentrated emissions from industrial sources, enabling more efficient carbon removal with lower energy requirements. Both methods are crucial for reducing atmospheric CO2, yet DAC provides broader application potential for negative emissions beyond point-source capture.

Table of Comparison

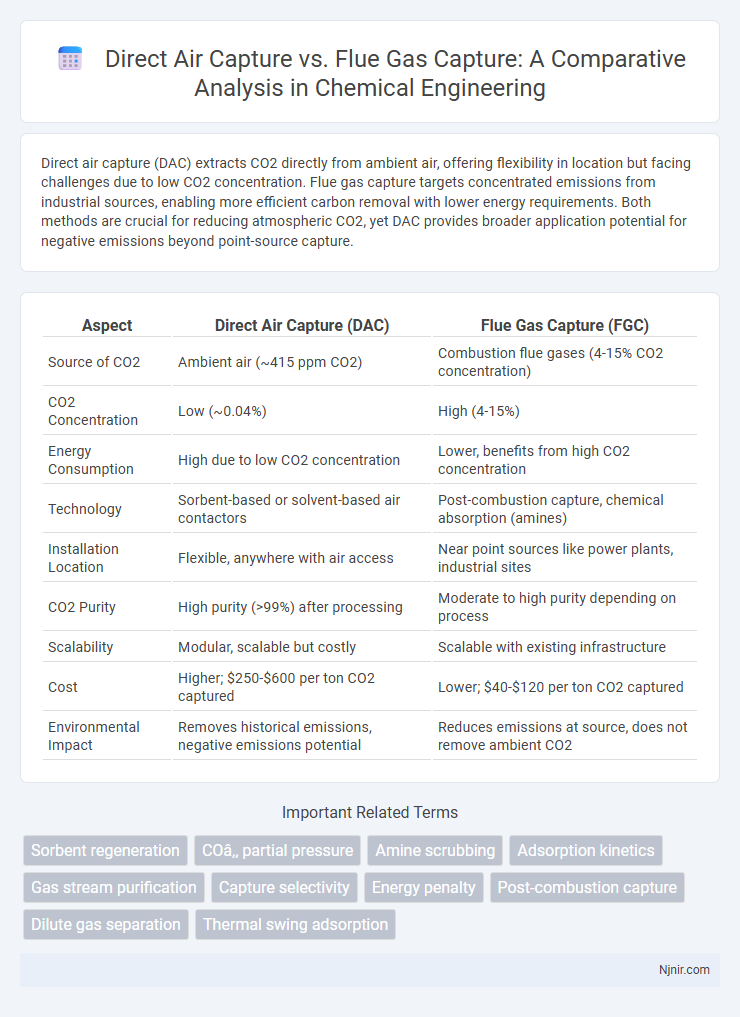

| Aspect | Direct Air Capture (DAC) | Flue Gas Capture (FGC) |

|---|---|---|

| Source of CO2 | Ambient air (~415 ppm CO2) | Combustion flue gases (4-15% CO2 concentration) |

| CO2 Concentration | Low (~0.04%) | High (4-15%) |

| Energy Consumption | High due to low CO2 concentration | Lower, benefits from high CO2 concentration |

| Technology | Sorbent-based or solvent-based air contactors | Post-combustion capture, chemical absorption (amines) |

| Installation Location | Flexible, anywhere with air access | Near point sources like power plants, industrial sites |

| CO2 Purity | High purity (>99%) after processing | Moderate to high purity depending on process |

| Scalability | Modular, scalable but costly | Scalable with existing infrastructure |

| Cost | Higher; $250-$600 per ton CO2 captured | Lower; $40-$120 per ton CO2 captured |

| Environmental Impact | Removes historical emissions, negative emissions potential | Reduces emissions at source, does not remove ambient CO2 |

Introduction to Carbon Capture Techniques

Direct air capture (DAC) extracts carbon dioxide directly from ambient air using chemical processes, offering flexibility in location and the potential for negative emissions. Flue gas capture involves capturing CO2 from exhaust gases emitted by industrial sources, typically more concentrated and easier to separate compared to ambient air. Both carbon capture techniques play crucial roles in reducing greenhouse gas emissions, with DAC targeting diffuse sources and flue gas capture focusing on point-source emissions.

Overview of Direct Air Capture (DAC)

Direct Air Capture (DAC) is a technology designed to extract carbon dioxide directly from ambient air, offering a scalable solution for negative emissions and combating climate change. Unlike Flue Gas Capture, which targets concentrated CO2 emissions from industrial sources, DAC operates on low-concentration CO2 in the atmosphere, using chemical sorbents or filters to capture and isolate carbon. DAC systems are energy-intensive but provide flexibility in location and the potential for permanent carbon storage or utilization.

Overview of Flue Gas Capture (FGC)

Flue Gas Capture (FGC) involves extracting carbon dioxide from industrial exhaust gases, primarily from power plants and manufacturing facilities, where CO2 concentrations range between 5-15%. This method utilizes chemical solvents or sorbents to selectively absorb CO2, enabling post-combustion carbon capture with relatively lower energy demand compared to direct air capture. FGC is considered a cost-effective and scalable solution for reducing greenhouse gas emissions from point sources with high CO2 purity in flue gas streams.

Comparative Mechanisms: DAC vs FGC

Direct air capture (DAC) operates by extracting CO2 directly from ambient air using chemical sorbents or solid adsorbents, enabling carbon removal regardless of emission source location. Flue gas capture (FGC) targets concentrated CO2 streams emitted from industrial sources, employing methods like amine-based absorption to separate CO2 from combustion gases. DAC's lower CO2 concentration in the air demands higher energy input and advanced materials compared to FGC, which benefits from higher capture efficiency due to elevated CO2 levels in flue gases.

Energy Efficiency Analysis

Direct air capture (DAC) typically requires significantly more energy compared to flue gas capture due to the lower concentration of CO2 in ambient air (around 0.04%) versus flue gas (often 10-15%). Flue gas capture benefits from higher CO2 partial pressures, which reduces the energy intensity for sorbent regeneration and compression. Energy efficiency analysis shows DAC processes can consume up to 2-3 times more thermal and electrical energy per ton of CO2 captured than flue gas capture systems.

Cost Considerations and Economic Viability

Direct air capture (DAC) systems incur higher costs, typically ranging from $250 to $600 per ton of CO2 captured, due to the low concentration of CO2 in ambient air requiring significant energy input and advanced materials. Flue gas capture is generally more economically viable, with costs between $40 and $120 per ton, as it processes concentrated CO2 streams from industrial emissions, reducing energy demand and capital expenses. Economic viability of DAC depends on scaling, technological innovation, and carbon pricing mechanisms, while flue gas capture benefits from integration with existing industrial processes and immediate emissions reduction incentives.

Material and Process Challenges

Direct air capture faces material challenges such as low CO2 concentration requiring highly selective sorbents with fast adsorption kinetics and durability under varying atmospheric conditions. Flue gas capture materials must withstand high temperatures and corrosive compounds like SOx and NOx, necessitating robust amine-based solvents or solid adsorbents with enhanced thermal stability and resistance to degradation. Process challenges include energy-intensive regeneration steps in both methods, with direct air capture demanding greater air handling and flue gas systems requiring integration with existing industrial infrastructure to minimize operational disruptions.

Scalability and Infrastructure Requirements

Direct air capture (DAC) technology requires significant infrastructure investments due to its need to process large volumes of ambient air with low CO2 concentrations, making scalability a major challenge compared to flue gas capture, which benefits from higher CO2 concentrations and existing industrial setups. Flue gas capture systems are more easily integrated into current power plants and industrial facilities, leveraging existing pipelines and compressors, thus reducing infrastructure complexity and enhancing scalability prospects. The energy intensity and cost per ton of CO2 captured remain critical factors, with DAC currently demanding higher operational energy inputs and broader deployment of renewable energy infrastructure to scale effectively.

Environmental Impact and Sustainability

Direct air capture (DAC) technology removes CO2 directly from ambient air, offering scalable carbon removal with minimal local emissions, but requires high energy inputs often sourced from renewable energy to maintain environmental sustainability. Flue gas capture captures CO2 from concentrated emissions of industrial sources, enabling efficient carbon removal at lower energy costs yet limited to point sources, and can reduce pollutants like SOx and NOx, enhancing local air quality. Both methods contribute significantly to carbon mitigation but DAC provides broader applicability for negative emissions, while flue gas capture supports immediate emission reduction and integration with existing industrial processes.

Future Prospects and Technological Innovations

Direct air capture (DAC) technologies are advancing with innovations such as solid sorbents and mineralization processes enhancing efficiency and scalability, positioning DAC as a vital tool for negative emissions in a carbon-neutral future. Flue gas capture continues to improve through the development of advanced solvents and membrane technologies, offering cost-effective carbon capture solutions integrated with industrial processes. Both capture methods benefit from increasing deployment of AI and machine learning to optimize operations, lower energy consumption, and reduce costs, driving their future potential in climate change mitigation.

Sorbent regeneration

Direct air capture requires lower-temperature sorbent regeneration due to dilute CO2 concentration, whereas flue gas capture demands higher-temperature regeneration because of elevated CO2 concentration and contaminant presence.

CO₂ partial pressure

Direct air capture operates at atmospheric CO2 partial pressures around 0.04%, requiring highly selective sorbents, whereas flue gas capture deals with elevated CO2 partial pressures typically between 5% and 15%, enabling more energy-efficient carbon separation.

Amine scrubbing

Amine scrubbing efficiently captures CO2 from flue gas by chemically absorbing concentrated emissions, whereas direct air capture uses amines to extract CO2 from ambient air with significantly lower concentration, requiring higher energy input and larger scale equipment.

Adsorption kinetics

Adsorption kinetics in direct air capture are slower due to low CO2 concentration, whereas flue gas capture benefits from faster kinetics driven by higher CO2 partial pressures.

Gas stream purification

Direct air capture purifies dilute atmospheric CO2 from ambient air using advanced sorbents or membranes, while flue gas capture focuses on separating higher-concentration CO2 from industrial emissions through chemical absorption or cryogenic methods.

Capture selectivity

Direct air capture exhibits lower capture selectivity due to dilute CO2 concentrations around 400 ppm, whereas flue gas capture achieves higher selectivity with concentrated CO2 levels typically between 4-15%.

Energy penalty

Direct air capture requires significantly higher energy input per ton of CO2 captured compared to flue gas capture due to the lower concentration of CO2 in ambient air versus concentrated flue gas streams.

Post-combustion capture

Post-combustion flue gas capture captures CO2 from concentrated emissions with lower energy costs, while direct air capture extracts CO2 from ambient air at lower concentrations but higher operational complexity.

Dilute gas separation

Direct air capture efficiently separates dilute CO2 concentrations (~400 ppm) from ambient air, whereas flue gas capture targets higher CO2 concentrations (5-15%) in combustion exhaust, making dilute gas separation more energy-intensive in direct air capture processes.

Thermal swing adsorption

Thermal swing adsorption in direct air capture efficiently removes CO2 from ambient air with low concentration, while in flue gas capture it targets higher CO2 concentrations from industrial emissions, optimizing energy use and adsorption capacity based on temperature-driven regeneration cycles.

Direct air capture vs Flue gas capture Infographic

njnir.com

njnir.com