HAZOP (Hazard and Operability Study) systematically identifies potential hazards and operability issues in chemical processes by examining deviations from design intent. LOPA (Layer of Protection Analysis) evaluates the effectiveness of existing safety layers to prevent or mitigate identified hazards from HAZOP, quantifying the risk and determining if additional safeguards are required. Combining HAZOP and LOPA enhances risk management by ensuring thorough hazard identification and robust risk evaluation in chemical engineering projects.

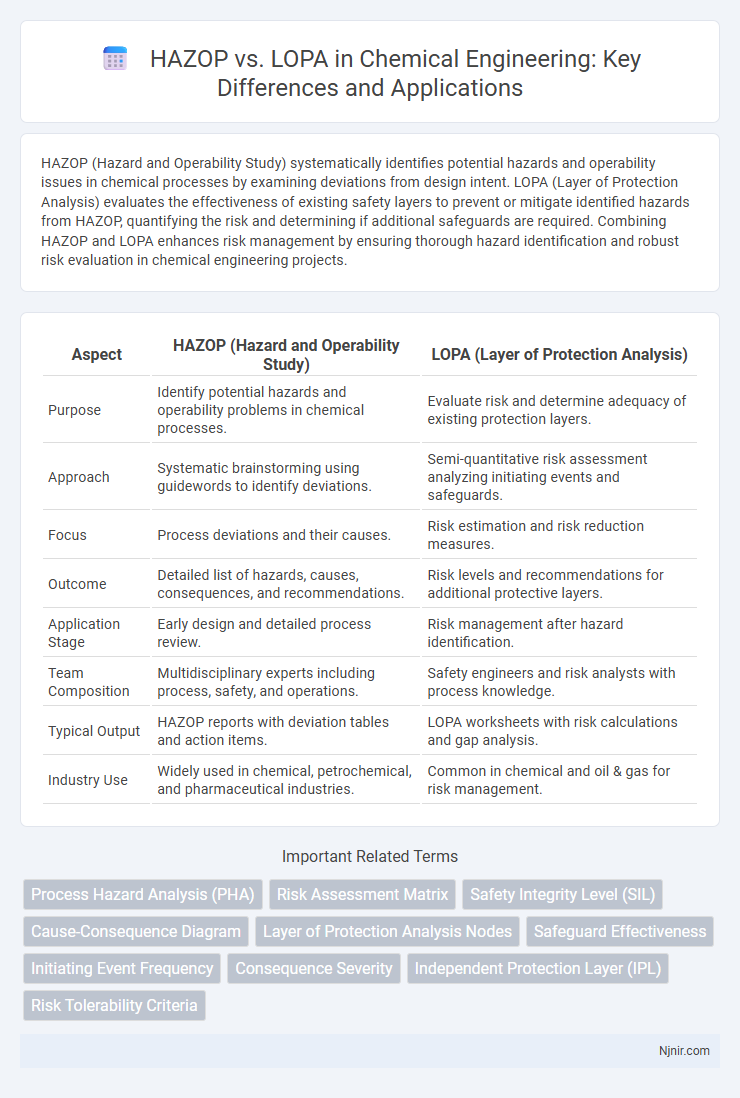

Table of Comparison

| Aspect | HAZOP (Hazard and Operability Study) | LOPA (Layer of Protection Analysis) |

|---|---|---|

| Purpose | Identify potential hazards and operability problems in chemical processes. | Evaluate risk and determine adequacy of existing protection layers. |

| Approach | Systematic brainstorming using guidewords to identify deviations. | Semi-quantitative risk assessment analyzing initiating events and safeguards. |

| Focus | Process deviations and their causes. | Risk estimation and risk reduction measures. |

| Outcome | Detailed list of hazards, causes, consequences, and recommendations. | Risk levels and recommendations for additional protective layers. |

| Application Stage | Early design and detailed process review. | Risk management after hazard identification. |

| Team Composition | Multidisciplinary experts including process, safety, and operations. | Safety engineers and risk analysts with process knowledge. |

| Typical Output | HAZOP reports with deviation tables and action items. | LOPA worksheets with risk calculations and gap analysis. |

| Industry Use | Widely used in chemical, petrochemical, and pharmaceutical industries. | Common in chemical and oil & gas for risk management. |

Introduction to HAZOP and LOPA

HAZOP (Hazard and Operability Study) is a systematic technique used to identify potential hazards and operability problems in industrial processes by examining deviations from design intentions. LOPA (Layer of Protection Analysis) evaluates the risk by quantifying the effectiveness of existing safety layers and determining if additional safeguards are necessary to prevent hazardous events. Both methods are essential in process safety management, with HAZOP providing qualitative hazard identification and LOPA offering a semi-quantitative risk assessment framework.

Key Principles of HAZOP

HAZOP (Hazard and Operability Study) revolves around systematically identifying potential hazards and operability problems through structured brainstorming using guidewords to analyze deviations in process parameters. Key principles include multidisciplinary team involvement, focusing on process deviations, and documenting causes, consequences, and safeguards to recommend improvements. In contrast, LOPA (Layer of Protection Analysis) quantifies risk by evaluating independent protection layers to determine if existing controls sufficiently mitigate hazards identified by studies like HAZOP.

Core Concepts of LOPA

LOPA (Layer of Protection Analysis) centers on quantifying risk by evaluating independent protection layers to prevent hazardous events, assigning risk reduction factors to each layer. Unlike HAZOP, which qualitatively identifies hazards and deviations through systematic guidewords, LOPA provides a semi-quantitative approach to estimate the likelihood of incident scenarios. Core concepts of LOPA include defining initiating events, identifying independent protection layers (IPLs), and calculating risk levels to ensure they meet acceptable risk criteria.

Comparative Analysis: HAZOP vs LOPA

HAZOP (Hazard and Operability Study) systematically identifies potential process hazards by examining deviations from design intentions using guide words, while LOPA (Layer of Protection Analysis) quantitatively evaluates the effectiveness of safeguards and their ability to reduce risk to acceptable levels. HAZOP excels in qualitative hazard identification and process safety insights, whereas LOPA provides a more precise risk assessment by incorporating frequency and consequence data to support decision-making on layers of protection. Combining HAZOP and LOPA enhances overall process safety management by integrating detailed hazard analysis with robust risk quantification and mitigation validation.

Strengths and Limitations of HAZOP

HAZOP excels in systematically identifying process deviations and potential hazards through detailed guideword analysis, making it highly effective for early-stage risk assessment. However, its limitations include subjectivity in interpretation, reliance on expert judgment, and difficulty quantifying risk severity and likelihood. Compared to LOPA, which quantifies risk and evaluates layers of protection, HAZOP primarily serves as a qualitative tool for hazard identification rather than risk evaluation.

Strengths and Limitations of LOPA

LOPA (Layer of Protection Analysis) excels in providing a semi-quantitative risk assessment by quantifying risk reduction layers and determining if safety measures meet acceptable risk levels. Its strength lies in simplifying complex hazard scenarios into manageable risk tiers, offering clear criteria for decision-making on additional safeguards. However, LOPA's limitations include reliance on the accuracy of initiating event frequencies and independent layer effectiveness, and it may not fully capture complex interactions or dynamic process changes compared to HAZOP's detailed qualitative hazard identification.

Integration of HAZOP and LOPA in Process Safety

HAZOP (Hazard and Operability Study) identifies potential hazards and operability issues in process systems through systematic brainstorming sessions, while LOPA (Layer of Protection Analysis) quantitatively evaluates the risk and the effectiveness of existing safety layers. Integrating HAZOP and LOPA enhances process safety by using HAZOP findings to pinpoint hazardous scenarios and applying LOPA to assess risk severity and determine the need for additional protective measures. This combined approach improves risk management accuracy and ensures robust safety system designs in chemical and industrial processes.

Application Scenarios: When to Use HAZOP or LOPA

HAZOP is best suited for early-stage process design reviews to systematically identify potential deviations and hazards in chemical plants or industrial processes. LOPA is applied after hazard identification, focusing on risk assessment by quantifying the effectiveness of independent protection layers and determining whether risk reduction measures are sufficient. Use HAZOP during detailed design phases to uncover process risks, and apply LOPA for decision-making on risk mitigation and safety integrity levels in high-risk scenarios.

Case Studies: HAZOP and LOPA in Chemical Engineering

Case studies in chemical engineering demonstrate that HAZOP (Hazard and Operability Study) systematically identifies potential deviations in process parameters to uncover safety risks, while LOPA (Layers of Protection Analysis) quantitatively evaluates the effectiveness of independent protection layers to mitigate those risks. For example, a refinery case showed HAZOP detecting a critical pressure deviation scenario, and subsequent LOPA assessment defined the required safety instrumented system integrity level to prevent catastrophic failure. Combining HAZOP and LOPA enhances risk management by integrating qualitative hazard recognition with quantitative risk reduction measures in complex chemical processes.

Best Practices for Effective Risk Assessment

HAZOP (Hazard and Operability Study) systematically identifies potential deviations and hazards in process systems by leveraging multidisciplinary team expertise to analyze design intent versus actual operations. LOPA (Layer of Protection Analysis) quantifies risk by evaluating the effectiveness of independent safety layers in preventing accident scenarios, enabling prioritization of risk mitigation measures based on acceptable risk criteria. Integrating HAZOP findings with LOPA allows organizations to conduct comprehensive, data-driven risk assessments that improve decision-making and optimize safety management systems.

Process Hazard Analysis (PHA)

HAZOP systematically identifies potential hazards and deviations in process operations, while LOPA quantitatively assesses risk by evaluating the effectiveness of independent protection layers within Process Hazard Analysis (PHA).

Risk Assessment Matrix

HAZOP identifies potential process deviations systematically, while LOPA evaluates risk by assigning severity and likelihood scores in a risk assessment matrix to establish independent protection layers.

Safety Integrity Level (SIL)

HAZOP identifies process hazards and deviations while LOPA quantifies risk for determining Safety Integrity Level (SIL) requirements to ensure appropriate safety instrumented system performance.

Cause-Consequence Diagram

HAZOP uses qualitative Cause-Consequence Diagrams to systematically identify process deviations and hazards, while LOPA quantitatively analyzes layers of protection based on identified causes and consequences to assess risk levels.

Layer of Protection Analysis Nodes

HAZOP identifies potential hazards and deviations in process nodes, while LOPA evaluates these nodes to quantify risk and determine the adequacy of existing layers of protection.

Safeguard Effectiveness

LOPA quantitatively evaluates Safeguard Effectiveness by assigning conditional probabilities to layers of protection, whereas HAZOP qualitatively identifies potential hazards and associated safeguards without directly measuring their effectiveness.

Initiating Event Frequency

HAZOP identifies potential deviations and causes without quantifying the Initiating Event Frequency, while LOPA specifically estimates Initiating Event Frequency to evaluate risk layers and safety instrumented functions.

Consequence Severity

HAZOP assesses consequence severity by identifying potential deviations and their impacts during process design, while LOPA quantifies consequence severity to determine the adequacy of independent protection layers for risk mitigation.

Independent Protection Layer (IPL)

LOPA specifically evaluates and quantifies Independent Protection Layers (IPLs) to determine risk reduction effectiveness, while HAZOP primarily identifies hazards and deviations without directly assessing IPL performance.

Risk Tolerability Criteria

HAZOP identifies potential hazards and deviations in processes, while LOPA quantitatively assesses risk against predefined Risk Tolerability Criteria to determine if existing safeguards are adequate or if additional protection layers are required.

HAZOP vs LOPA Infographic

njnir.com

njnir.com