Lab-on-a-chip technology enables rapid, cost-effective testing of chemical processes on a microscale, facilitating precise control over reaction conditions and minimizing reagent consumption. Pilot plants offer a scalable environment to validate and optimize processes before full-scale production, bridging the gap between laboratory research and industrial manufacturing. Combining both approaches accelerates development by integrating detailed microreactor data with practical operational insights from pilot-scale trials.

Table of Comparison

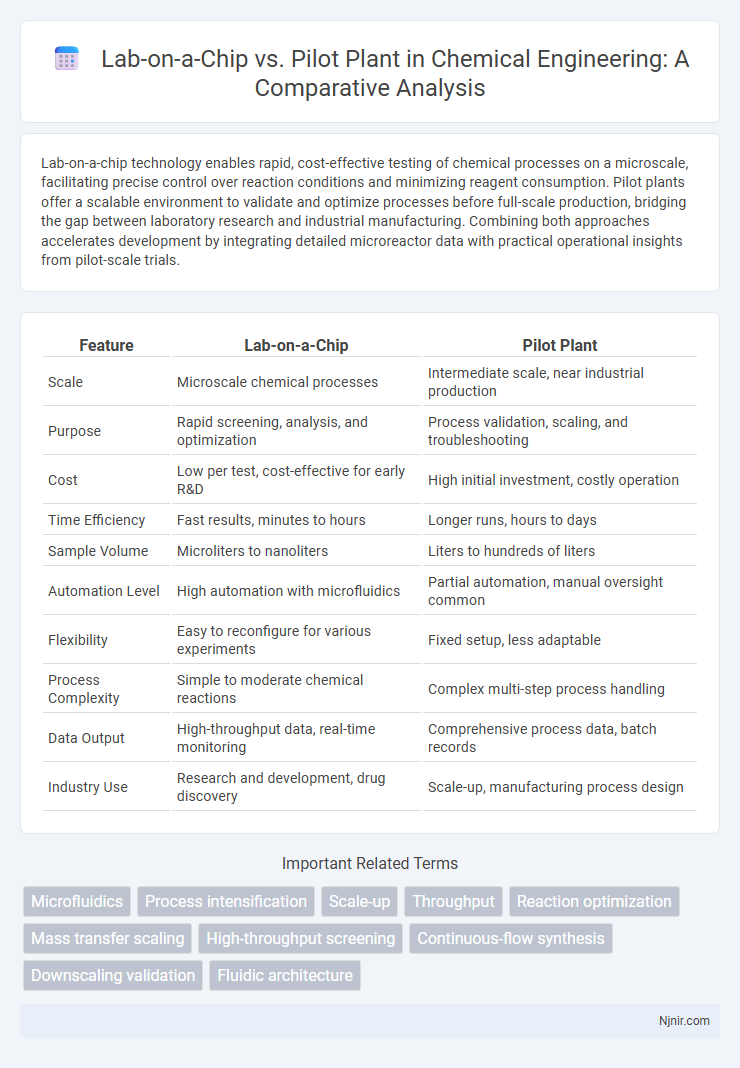

| Feature | Lab-on-a-Chip | Pilot Plant |

|---|---|---|

| Scale | Microscale chemical processes | Intermediate scale, near industrial production |

| Purpose | Rapid screening, analysis, and optimization | Process validation, scaling, and troubleshooting |

| Cost | Low per test, cost-effective for early R&D | High initial investment, costly operation |

| Time Efficiency | Fast results, minutes to hours | Longer runs, hours to days |

| Sample Volume | Microliters to nanoliters | Liters to hundreds of liters |

| Automation Level | High automation with microfluidics | Partial automation, manual oversight common |

| Flexibility | Easy to reconfigure for various experiments | Fixed setup, less adaptable |

| Process Complexity | Simple to moderate chemical reactions | Complex multi-step process handling |

| Data Output | High-throughput data, real-time monitoring | Comprehensive process data, batch records |

| Industry Use | Research and development, drug discovery | Scale-up, manufacturing process design |

Introduction to Lab-on-a-Chip and Pilot Plant Technologies

Lab-on-a-chip technology integrates multiple laboratory functions on a single micro-scale chip, enabling rapid and precise analysis with minimal reagent use and enhanced portability for applications in diagnostics and chemical synthesis. Pilot plant technology involves scalable, intermediate-scale systems designed to simulate full-scale industrial processes, allowing for process optimization, testing, and validation before commercial production. Both technologies serve critical roles in bridging research and manufacturing, with lab-on-a-chip focusing on miniaturization and high-throughput screening, while pilot plants emphasize scale-up and process feasibility.

Core Differences between Lab-on-a-Chip and Pilot Plant Systems

Lab-on-a-chip systems integrate microfluidic channels and sensors on a single chip, enabling precise manipulation of small fluid volumes at the microscale for rapid analysis and testing. Pilot plant systems operate at a larger scale, simulating industrial processes to optimize production parameters and scale-up from laboratory experiments to full-scale manufacturing. The core difference lies in their scale and purpose: lab-on-a-chip focuses on microscale experimentation and high-throughput screening, while pilot plants emphasize process optimization and validation at a near-industrial scale.

Scalability: From Microfluidics to Industrial Scale

Lab-on-a-chip devices enable precise microfluidic control at microscale, ideal for early-stage research and rapid prototyping of chemical or biological processes. Pilot plants provide a crucial intermediate step, scaling up from lab-on-a-chip to industrial production volumes while maintaining process efficiency and product consistency. Efficient transition from microfluidics to pilot plant scale relies on robust process engineering and integration of scalable unit operations for seamless industrial implementation.

Cost Effectiveness: Investment and Operational Expenses

Lab-on-a-chip technology significantly reduces investment and operational expenses compared to pilot plants by miniaturizing equipment and minimizing reagent consumption, lowering capital and running costs. Pilot plants, involving larger-scale operations and complex infrastructure, require higher initial investment and ongoing maintenance expenses, making them less cost-effective for early-stage testing and process optimization. The compact design and automation potential of lab-on-a-chip systems enable rapid experimentation and lower labor costs, enhancing overall cost efficiency.

Process Optimization and Control Capabilities

Lab-on-a-chip devices enable precise process optimization by integrating microfluidic channels for real-time monitoring and control of chemical reactions at a microscale, enhancing reaction efficiency and reducing material usage. Pilot plants offer scalable process control capabilities, allowing for the simulation of industrial conditions and the optimization of parameters such as temperature, pressure, and flow rates to improve overall production performance. While lab-on-a-chip systems excel in detailed mechanistic studies and rapid adjustments, pilot plants provide comprehensive data on process stability, scalability, and control under practical manufacturing conditions.

Analytical Precision: Data Quality and Reproducibility

Lab-on-a-chip devices offer high analytical precision with microfluidic control enabling rapid, accurate, and reproducible data suitable for early-stage experiments. Pilot plants provide scalable analytical processes that replicate industrial conditions, ensuring data quality aligned with commercial production requirements. The micro-scale environment of lab-on-a-chip ensures minimal sample variation, while pilot plants emphasize consistency across larger batches for robust reproducibility.

Flexibility and Customization in Chemical Processes

Lab-on-a-chip technology offers unparalleled flexibility and customization in chemical processes by enabling microscale experiments with precise control over reaction conditions and rapid adjustments to parameters. Pilot plants provide scalable, semi-continuous production with customization capabilities suited for process validation but lack the rapid adaptability and fine-tuning available in lab-on-a-chip systems. The integration of microfluidic design in lab-on-a-chip platforms facilitates high-throughput screening and tailored process optimization that pilot plants cannot achieve without significant redesign and cost.

Safety Considerations and Risk Management

Lab-on-a-chip devices offer enhanced safety by minimizing reagent volumes and reducing exposure to hazardous chemicals, which significantly lowers the risk of contamination and accidents during experimental procedures. In contrast, pilot plants require comprehensive safety protocols due to scale-up complexities, including handling larger quantities of raw materials and potential exposure to toxic substances, necessitating robust risk management systems such as emergency shutdown procedures and environmental controls. Both approaches demand rigorous hazard identification and mitigation strategies, but the microfluidic scale of lab-on-a-chip technology inherently reduces operational risks compared to pilot plant operations.

Integration with Digital and Automated Systems

Lab-on-a-chip devices integrate advanced microfluidics with digital sensors and automated control systems, enabling real-time data acquisition and precise manipulation of chemical or biological processes on a miniature scale. Pilot plants incorporate scalable automation platforms and digital twin technologies to simulate and optimize production workflows, facilitating seamless data exchange between equipment and centralized control systems. Both systems leverage Internet of Things (IoT) connectivity and machine learning algorithms to enhance process monitoring and reduce human intervention, but lab-on-a-chip emphasizes microscale precision while pilot plants focus on industrial-scale application.

Future Trends in Chemical Process Development

Lab-on-a-chip technology enables rapid, miniaturized chemical analysis and experimentation, significantly accelerating the screening phase in chemical process development. Pilot plants remain essential for scaling up processes to validate operational parameters and generate data for commercial production, bridging the gap between laboratory results and industrial feasibility. Future trends highlight the integration of lab-on-a-chip systems with advanced automation and AI-driven analytics to optimize pilot plant design and reduce time-to-market for chemical products.

Microfluidics

Lab-on-a-chip utilizes microfluidics to miniaturize chemical and biological processes at a microscale, enabling rapid, cost-effective experimentation compared to the larger-scale, resource-intensive pilot plant operations.

Process intensification

Lab-on-a-chip technology enables rapid process intensification at microscale through integrated analytical and reaction functionalities, whereas pilot plants achieve process intensification by scaling up experiments to optimize production parameters in a controlled macro environment.

Scale-up

Lab-on-a-chip platforms enable microscale experiments for rapid prototyping and optimization, while pilot plants facilitate scale-up by validating processes at intermediate volumes before full-scale production.

Throughput

Lab-on-a-chip devices enable high-throughput screening with microscale sample volumes, while pilot plants achieve larger-scale throughput suitable for process optimization and scale-up before full production.

Reaction optimization

Lab-on-a-chip enables precise reaction optimization at microscale by rapidly screening conditions, whereas pilot plants facilitate scaling optimized reactions to intermediate production volumes for process validation.

Mass transfer scaling

Lab-on-a-chip devices enable precise mass transfer scaling through microfluidic control, whereas pilot plants face challenges in replicating microscale mass transfer efficiencies in larger, heterogeneous systems.

High-throughput screening

Lab-on-a-chip technology enables rapid high-throughput screening by miniaturizing experimental processes, whereas pilot plants provide scaled-up testing with slower throughput but closer to industrial production conditions.

Continuous-flow synthesis

Lab-on-a-chip devices enable precise microscale continuous-flow synthesis with rapid reaction control, while pilot plants scale up continuous-flow processes for industrial production and process optimization.

Downscaling validation

Lab-on-a-chip devices facilitate precise downscaling validation by replicating pilot plant chemical processes on microscale platforms, enhancing efficiency and reducing costs.

Fluidic architecture

Lab-on-a-chip devices feature highly miniaturized fluidic architectures enabling precise microscale fluid control, whereas pilot plants utilize larger-scale fluidic systems designed for process validation and scalability in industrial applications.

Lab-on-a-chip vs pilot plant Infographic

njnir.com

njnir.com