Direct air capture (DAC) removes CO2 directly from ambient air, offering flexibility in location and potential for negative emissions but requires high energy input due to low CO2 concentration. Post-combustion capture targets CO2 in flue gases from industrial processes, benefiting from higher CO2 concentrations and existing infrastructure compatibility but is limited to point sources. Both methods play crucial roles in reducing greenhouse gas emissions, with DAC supporting decentralized carbon removal and post-combustion capture enhancing emission control at power plants.

Table of Comparison

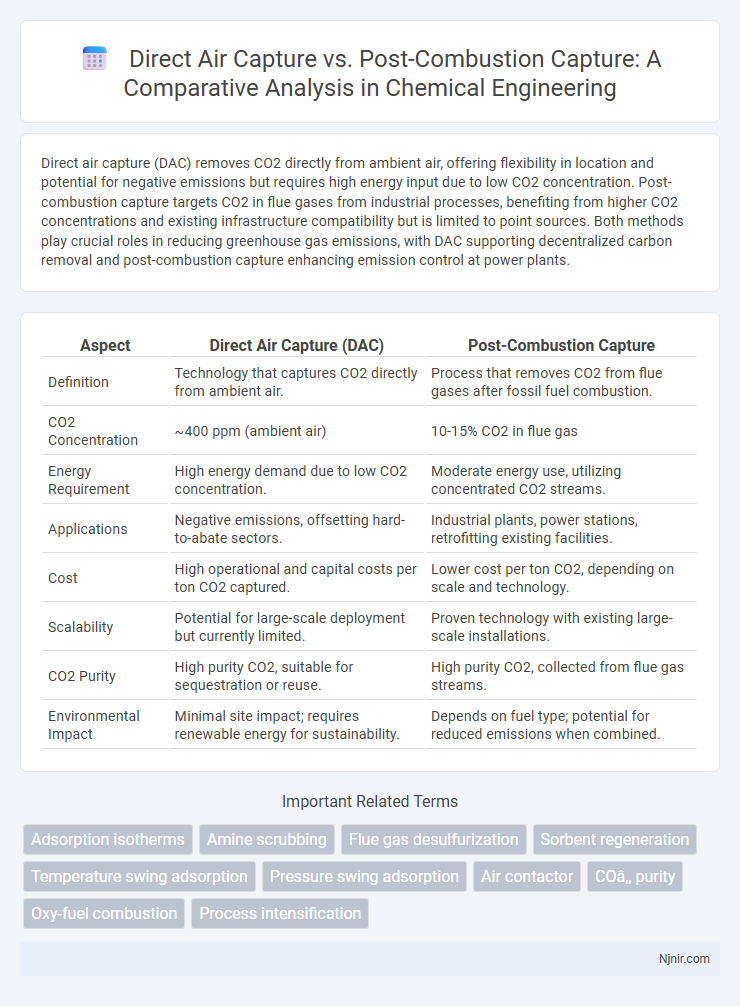

| Aspect | Direct Air Capture (DAC) | Post-Combustion Capture |

|---|---|---|

| Definition | Technology that captures CO2 directly from ambient air. | Process that removes CO2 from flue gases after fossil fuel combustion. |

| CO2 Concentration | ~400 ppm (ambient air) | 10-15% CO2 in flue gas |

| Energy Requirement | High energy demand due to low CO2 concentration. | Moderate energy use, utilizing concentrated CO2 streams. |

| Applications | Negative emissions, offsetting hard-to-abate sectors. | Industrial plants, power stations, retrofitting existing facilities. |

| Cost | High operational and capital costs per ton CO2 captured. | Lower cost per ton CO2, depending on scale and technology. |

| Scalability | Potential for large-scale deployment but currently limited. | Proven technology with existing large-scale installations. |

| CO2 Purity | High purity CO2, suitable for sequestration or reuse. | High purity CO2, collected from flue gas streams. |

| Environmental Impact | Minimal site impact; requires renewable energy for sustainability. | Depends on fuel type; potential for reduced emissions when combined. |

Overview of Carbon Capture Technologies

Direct air capture (DAC) technology involves extracting CO2 directly from ambient air using chemical processes, while post-combustion capture captures CO2 from flue gases emitted by power plants or industrial sources. DAC offers flexibility in location and scalability but requires higher energy input due to the low concentration of CO2 in ambient air compared to flue gas. Post-combustion capture is widely implemented with existing infrastructure, utilizing solvents or sorbents to separate CO2, making it cost-effective for large point sources but limited to emission-intensive facilities.

Fundamentals of Direct Air Capture

Direct air capture (DAC) technology extracts carbon dioxide directly from ambient air using chemical processes involving sorbents or solvents, enabling the reduction of atmospheric CO2 levels regardless of emission sources. Unlike post-combustion capture which targets CO2 from flue gases after combustion in power plants or industrial facilities, DAC operates independently from emission sites, providing a versatile solution for achieving negative emissions. Key fundamentals of DAC include low CO2 concentration in air (~420 ppm), energy-intensive sorbent regeneration, and integration with carbon storage or utilization pathways to maximize climate impact.

Principles of Post-Combustion Capture

Post-combustion capture operates by extracting carbon dioxide from flue gases emitted after fuel combustion in power plants or industrial processes, typically using chemical solvents like amines to absorb CO2. This method targets low CO2 concentrations in exhaust gases, enabling retrofitting on existing facilities without altering combustion processes. Its efficiency depends on solvent regeneration, energy consumption, and the capacity to handle large gas volumes, making it a widely deployed carbon capture technology for reducing emissions from fossil fuel use.

Energy Requirements and Efficiency Comparison

Direct air capture (DAC) typically requires between 1500 to 2500 kWh of energy per ton of CO2 captured due to the low concentration of CO2 in ambient air, making it more energy-intensive compared to post-combustion capture (PCC), which averages around 200 to 400 kWh per ton from flue gas with higher CO2 concentrations. DAC systems often rely on renewable energy sources to improve sustainability, while PCC benefits from integration with existing power plant heat and steam, enhancing overall process efficiency. Despite higher energy demands, DAC offers flexibility in location and scalability, whereas PCC's efficiency is constrained by plant design and the chemical absorption process, typically achieving 85-90% CO2 capture rates.

Technological Readiness and Scalability

Direct air capture (DAC) technology is at a lower technological readiness level compared to post-combustion capture, with most DAC systems still in pilot or demonstration phases while post-combustion capture benefits from mature industrial deployment in power plants and industrial facilities. Scalability challenges for DAC include high energy requirements and significant capital costs, limiting large-scale implementation despite its advantage in capturing CO2 directly from the atmosphere. Post-combustion capture technologies, such as amine-based solvents, offer higher scalability due to integration with existing infrastructure but are limited to point sources with concentrated CO2 emissions.

Material Selection and Sorbent Performance

Direct air capture (DAC) primarily utilizes advanced solid sorbents like amine-functionalized polymers and metal-organic frameworks (MOFs) designed for low CO2 concentration, while post-combustion capture favors liquid amine solutions such as monoethanolamine (MEA) optimized for high CO2 concentration in flue gases. Material selection in DAC demands high sorbent stability, rapid adsorption/desorption kinetics, and low energy consumption under dilute CO2 conditions, whereas post-combustion capture materials prioritize strong CO2 affinity and thermal resilience to repeated regeneration cycles at higher partial pressures. Sorbent performance metrics for DAC focus on cycling capacity and selectivity at ambient conditions, contrasting with post-combustion capture's emphasis on amine degradation rate, solvent loss, and operational cost-effectiveness in industrial exhaust environments.

Environmental Impact Assessment

Direct air capture (DAC) technology removes CO2 directly from the atmosphere with a lower land and water footprint compared to post-combustion capture, which primarily targets emissions from power plants and industrial sources. Lifecycle assessments highlight that DAC systems can achieve negative emissions when powered by renewable energy, whereas post-combustion capture relies on fossil-fuel-based processes that may generate secondary pollutants. Environmental impact assessments reveal that DAC offers broader climate mitigation potential by addressing diffuse emissions, while post-combustion capture is more limited to point-source emission reductions with associated infrastructure challenges.

Economic Feasibility and Cost Analysis

Direct air capture (DAC) technologies face higher operational costs, frequently ranging from $250 to $600 per ton of CO2 captured, due to the low atmospheric concentration of CO2 and energy-intensive processes. In contrast, post-combustion capture systems, commonly integrated with power plants, typically incur lower costs around $40 to $120 per ton of CO2, benefiting from higher flue gas CO2 concentrations and established infrastructure. Economic feasibility studies highlight that while DAC enables broader CO2 removal scope, post-combustion capture remains more cost-effective for industrial-scale carbon mitigation in the near term.

Integration with Existing Infrastructure

Direct air capture (DAC) operates independently of power plants and industrial facilities, allowing flexible placement but requiring new infrastructure for CO2 transport and storage. Post-combustion capture integrates directly with existing power plants by retrofitting capture units to flue gas streams, leveraging current equipment and pipelines. This integration advantage reduces initial capital costs and facilitates faster deployment compared to DAC, which faces higher costs and logistical challenges for scaling.

Future Prospects and Research Directions

Direct air capture (DAC) technology is advancing with a focus on enhancing sorbent efficiency and reducing energy consumption to achieve scalable carbon removal from the atmosphere, aiming for gigaton-level CO2 extraction by 2050. Post-combustion capture research prioritizes improving solvent regeneration processes and integrating carbon capture systems with existing power plants to lower operational costs and increase capture rates. Future prospects emphasize hybrid systems combining DAC and post-combustion methods, supported by innovations in materials science and process optimization to drive widespread deployment and achieve net-zero emission targets.

Adsorption isotherms

Direct air capture relies on strongly selective adsorption isotherms at low CO2 partial pressures, whereas post-combustion capture involves adsorption isotherms optimized for higher CO2 concentrations in flue gas streams.

Amine scrubbing

Amine scrubbing in post-combustion capture efficiently removes CO2 from flue gases using chemical solvents, whereas direct air capture employs similar amine-based sorbents but captures CO2 directly from ambient air with significantly lower concentrations.

Flue gas desulfurization

Direct air capture technology offers broader CO2 removal potential but faces challenges with low atmospheric concentrations, while post-combustion capture combined with flue gas desulfurization effectively reduces sulfur oxides and enhances CO2 capture efficiency from concentrated flue gas streams.

Sorbent regeneration

Direct air capture requires higher energy input for sorbent regeneration due to lower CO2 concentration in ambient air compared to post-combustion capture, which benefits from flue gas's higher CO2 levels enabling more efficient sorbent regeneration.

Temperature swing adsorption

Temperature swing adsorption in direct air capture offers lower energy consumption and higher CO2 selectivity compared to post-combustion capture, making it more efficient for capturing dilute atmospheric CO2.

Pressure swing adsorption

Pressure swing adsorption enhances post-combustion capture efficiency by selectively adsorbing CO2 at high pressure and regenerating adsorbents at low pressure, whereas direct air capture requires more energy due to lower atmospheric CO2 concentration.

Air contactor

Direct air capture uses large-scale air contactors to extract CO2 directly from ambient air, while post-combustion capture employs smaller air contactors integrated with flue gas treatment systems to capture CO2 from power plant emissions.

CO₂ purity

Direct air capture achieves higher CO2 purity levels, typically exceeding 99%, compared to post-combustion capture methods that often produce CO2 with purity levels around 85-95%.

Oxy-fuel combustion

Oxy-fuel combustion enhances post-combustion capture efficiency by producing a concentrated CO2 stream, while direct air capture independently captures CO2 from ambient air with higher energy demands.

Process intensification

Direct air capture employs advanced sorbents and modular contactors for higher CO2 concentration efficiency, while post-combustion capture intensifies processes through solvent regeneration and heat integration to optimize flue gas CO2 separation.

Direct air capture vs post-combustion capture Infographic

njnir.com

njnir.com