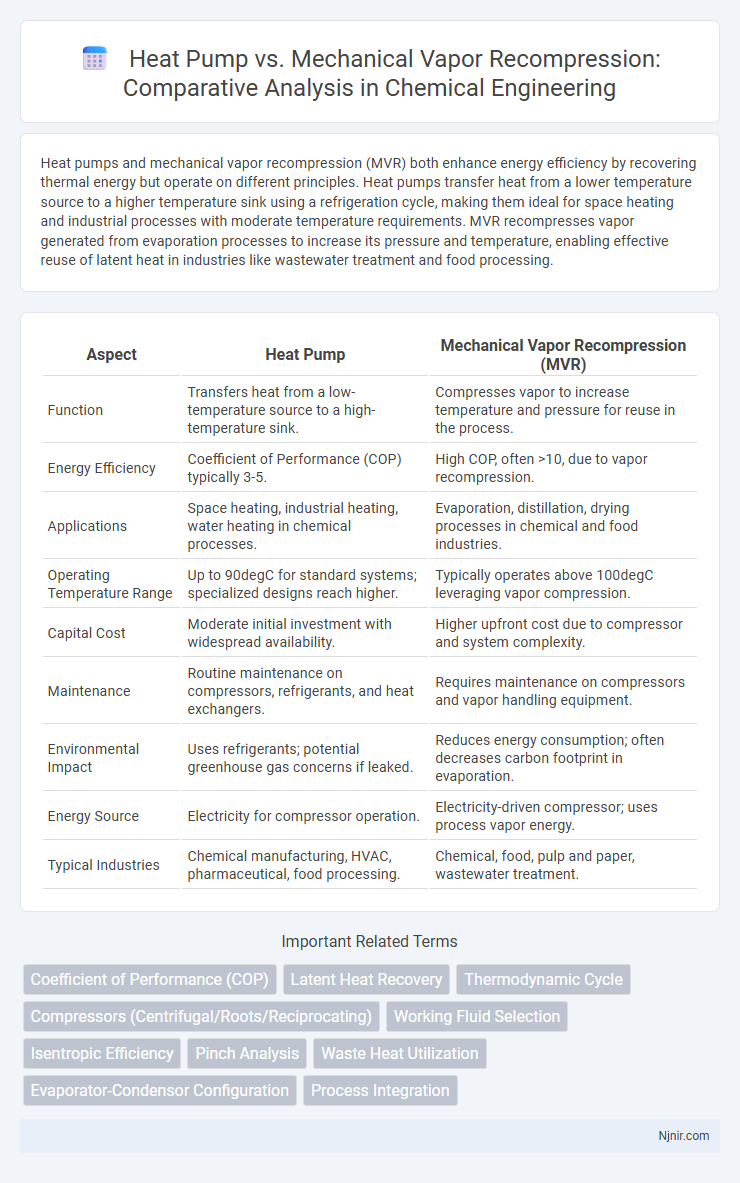

Heat pumps and mechanical vapor recompression (MVR) both enhance energy efficiency by recovering thermal energy but operate on different principles. Heat pumps transfer heat from a lower temperature source to a higher temperature sink using a refrigeration cycle, making them ideal for space heating and industrial processes with moderate temperature requirements. MVR recompresses vapor generated from evaporation processes to increase its pressure and temperature, enabling effective reuse of latent heat in industries like wastewater treatment and food processing.

Table of Comparison

| Aspect | Heat Pump | Mechanical Vapor Recompression (MVR) |

|---|---|---|

| Function | Transfers heat from a low-temperature source to a high-temperature sink. | Compresses vapor to increase temperature and pressure for reuse in the process. |

| Energy Efficiency | Coefficient of Performance (COP) typically 3-5. | High COP, often >10, due to vapor recompression. |

| Applications | Space heating, industrial heating, water heating in chemical processes. | Evaporation, distillation, drying processes in chemical and food industries. |

| Operating Temperature Range | Up to 90degC for standard systems; specialized designs reach higher. | Typically operates above 100degC leveraging vapor compression. |

| Capital Cost | Moderate initial investment with widespread availability. | Higher upfront cost due to compressor and system complexity. |

| Maintenance | Routine maintenance on compressors, refrigerants, and heat exchangers. | Requires maintenance on compressors and vapor handling equipment. |

| Environmental Impact | Uses refrigerants; potential greenhouse gas concerns if leaked. | Reduces energy consumption; often decreases carbon footprint in evaporation. |

| Energy Source | Electricity for compressor operation. | Electricity-driven compressor; uses process vapor energy. |

| Typical Industries | Chemical manufacturing, HVAC, pharmaceutical, food processing. | Chemical, food, pulp and paper, wastewater treatment. |

Introduction to Heat Pump and Mechanical Vapor Recompression

Heat pumps transfer thermal energy by extracting heat from a low-temperature source and upgrading it to a higher temperature using mechanical work, offering efficient heating and cooling solutions. Mechanical vapor recompression (MVR) enhances steam or vapor temperature and pressure by compressing vapor generated during evaporation processes, enabling energy recovery and reuse in industrial applications. Both technologies improve energy efficiency by leveraging thermodynamic principles to recycle heat, but they differ in mechanisms and typical use cases.

Fundamental Principles of Heat Pumps

Heat pumps operate on the principle of transferring heat from a lower temperature source to a higher temperature sink using a refrigeration cycle involving evaporation, compression, condensation, and expansion. Mechanical vapor recompression (MVR), by contrast, recycles vapor mechanically compressed to higher pressure and temperature for reuse in thermal processes, enhancing energy efficiency. Heat pumps rely on external energy input to drive the refrigerant cycle, making them effective for heating and cooling applications with coefficient of performance (COP) values typically ranging from 3 to 5.

Operating Mechanism of Mechanical Vapor Recompression

Mechanical Vapor Recompression (MVR) operates by capturing low-pressure vapor generated from a thermal process and compressing it to a higher pressure and temperature using a mechanical compressor, enabling the vapor to be reused as a heat source. Unlike heat pumps that transfer heat from ambient air or ground, MVR recycles latent heat from vapor within industrial distillation, evaporation, or drying systems, significantly enhancing energy efficiency. This mechanism reduces external energy consumption by converting waste vapor into useful heating energy, optimizing thermal processes in sectors like chemical, food, and wastewater treatment.

Comparative Energy Efficiency Analysis

Heat pumps achieve energy efficiency by transferring thermal energy from low-temperature sources to higher-temperature sinks, typically reaching coefficient of performance (COP) values between 3 and 5, making them suitable for space heating and industrial processes. Mechanical vapor recompression (MVR) systems enhance energy efficiency by recycling latent heat of vaporized liquids, often attaining higher COP values around 6 to 10, effectively reducing steam consumption in evaporation and distillation processes. Comparative analyses reveal MVR systems generally outperform heat pumps in energy savings for vapor phase applications, while heat pumps offer greater flexibility and lower initial costs for moderate temperature heating needs.

Applications in Chemical Engineering Processes

Heat pumps in chemical engineering enhance energy efficiency by transferring heat from low to high temperature areas, ideal for distillation, drying, and crystallization processes. Mechanical vapor recompression (MVR) is favored in evaporation and concentration applications, where it compresses and recycles vapor, significantly reducing steam consumption and operational costs. Both technologies optimize thermal energy usage, but MVR is particularly effective in large-scale evaporation systems requiring high energy recovery.

Technical Advantages and Limitations

Heat pumps offer high energy efficiency by transferring heat from low-temperature sources, supporting a wide range of applications with moderate temperatures up to 90degC, but their performance decreases significantly at higher temperature demands. Mechanical vapor recompression (MVR) achieves superior energy savings by compressing and reusing vapor's latent heat, making it highly effective for industrial processes requiring steam at elevated temperatures, though it necessitates complex maintenance and higher capital investment. Both technologies reduce fossil fuel dependency, yet heat pumps excel in simplicity and operational costs, while MVR is preferred for large-scale, high-temperature applications despite its technical complexity and sensitivity to process variations.

Economic Considerations and Cost-Benefit Analysis

Heat pumps generally offer lower initial capital costs and reduced operational expenses due to higher energy efficiency compared to mechanical vapor recompression (MVR) systems, which require significant power input but benefit from robust performance in high-capacity industrial applications. MVR systems have a higher upfront investment but achieve rapid payback periods through substantial savings in steam consumption and reduced thermal energy requirements, making them cost-effective for large-scale processes with consistent operating loads. The cost-benefit analysis favors heat pumps in moderate-demand applications with fluctuating loads, while MVR provides superior economic returns in continuous high-demand environments by maximizing energy recovery and minimizing waste heat.

Environmental Impact and Sustainability

Heat pumps deliver sustainable heating by efficiently transferring ambient heat with COPs often exceeding 4, reducing fossil fuel reliance and greenhouse gas emissions. Mechanical vapor recompression (MVR) recycles vapor energy in industrial processes, slashing energy consumption by up to 80% compared to traditional methods and minimizing carbon footprint. Both technologies advance environmental sustainability, with heat pumps excelling in residential and commercial heating, while MVR is pivotal in eco-friendly industrial vapor management.

Integration into Existing Chemical Plant Infrastructure

Heat pumps offer straightforward integration into existing chemical plant infrastructure due to their compact design and compatibility with standard refrigerants, enabling efficient heat recovery without extensive retrofitting. Mechanical vapor recompression (MVR) systems require more complex modifications, including the installation of compressors and vapor handling units, but provide higher energy savings by reusing latent heat within distillation or evaporation processes. Selecting between heat pumps and MVR depends on the plant's existing layout, process requirements, and available space for new equipment.

Future Trends and Technological Advancements

Heat pumps are evolving with enhanced coefficient of performance (COP) through the integration of magnetic and electrocaloric cooling technologies, promising higher energy efficiency in residential and industrial heating applications. Mechanical vapor recompression (MVR) systems are advancing by incorporating variable frequency drives and smart control algorithms, enabling adaptive energy consumption and improved process integration in wastewater treatment and organic solvent recovery. Future trends indicate a convergence of IoT-enabled predictive maintenance and AI-driven optimization in both heat pump and MVR technologies, driving significant reductions in carbon footprint and operational costs.

Coefficient of Performance (COP)

Mechanical vapor recompression typically achieves a higher Coefficient of Performance (COP) than conventional heat pumps by recycling latent heat through vapor compression.

Latent Heat Recovery

Mechanical vapor recompression recovers latent heat more efficiently than conventional heat pumps by compressing and reusing vapor, significantly reducing energy consumption in industrial processes.

Thermodynamic Cycle

Mechanical vapor recompression achieves higher thermodynamic cycle efficiency than heat pumps by recycling vapor energy through compression, reducing energy consumption in industrial heating processes.

Compressors (Centrifugal/Roots/Reciprocating)

Mechanical vapor recompression primarily relies on centrifugal and roots compressors for efficient vapor compression, while heat pumps commonly utilize reciprocating compressors to optimize energy transfer and system performance.

Working Fluid Selection

Heat pump systems typically use refrigerants like R134a or ammonia optimized for thermal conductivity and pressure levels, whereas mechanical vapor recompression preferentially employs steam or water vapor to maximize energy efficiency in vapor phase.

Isentropic Efficiency

Mechanical vapor recompression typically achieves higher isentropic efficiency than heat pumps, resulting in greater energy savings for industrial vapor compression processes.

Pinch Analysis

Pinch Analysis reveals that heat pumps offer higher thermodynamic efficiency in low-temperature applications, while mechanical vapor recompression excels in scenarios with close temperature pinch points due to better heat recovery and reduced exergy losses.

Waste Heat Utilization

Mechanical vapor recompression maximizes waste heat utilization by recycling latent heat through vapor compression, whereas heat pumps primarily transfer sensible heat, making MVR more energy-efficient for industrial waste heat recovery.

Evaporator-Condensor Configuration

Mechanical vapor recompression systems utilize integrated evaporator-condenser units that enhance thermal efficiency by recycling latent heat, whereas heat pumps typically employ separate evaporator and condenser components optimized for distinct heat exchange processes.

Process Integration

Mechanical vapor recompression achieves higher process integration efficiency than heat pumps by recycling latent heat through vapor compression, minimizing external energy consumption in industrial heating systems.

Heat pump vs Mechanical vapor recompression Infographic

njnir.com

njnir.com