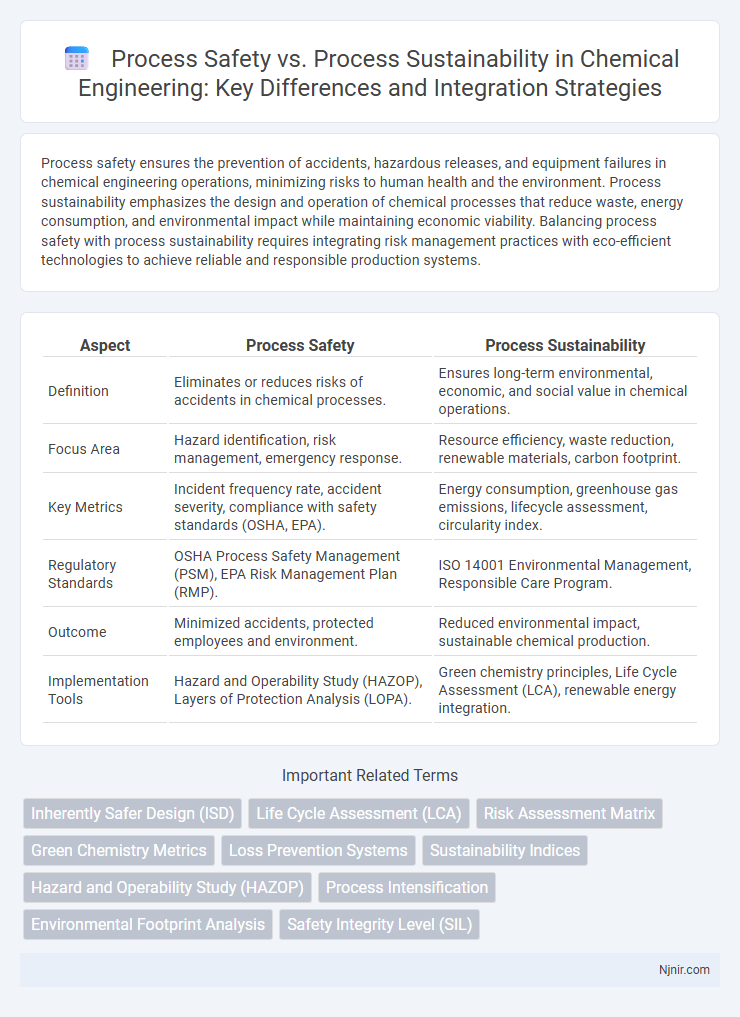

Process safety ensures the prevention of accidents, hazardous releases, and equipment failures in chemical engineering operations, minimizing risks to human health and the environment. Process sustainability emphasizes the design and operation of chemical processes that reduce waste, energy consumption, and environmental impact while maintaining economic viability. Balancing process safety with process sustainability requires integrating risk management practices with eco-efficient technologies to achieve reliable and responsible production systems.

Table of Comparison

| Aspect | Process Safety | Process Sustainability |

|---|---|---|

| Definition | Eliminates or reduces risks of accidents in chemical processes. | Ensures long-term environmental, economic, and social value in chemical operations. |

| Focus Area | Hazard identification, risk management, emergency response. | Resource efficiency, waste reduction, renewable materials, carbon footprint. |

| Key Metrics | Incident frequency rate, accident severity, compliance with safety standards (OSHA, EPA). | Energy consumption, greenhouse gas emissions, lifecycle assessment, circularity index. |

| Regulatory Standards | OSHA Process Safety Management (PSM), EPA Risk Management Plan (RMP). | ISO 14001 Environmental Management, Responsible Care Program. |

| Outcome | Minimized accidents, protected employees and environment. | Reduced environmental impact, sustainable chemical production. |

| Implementation Tools | Hazard and Operability Study (HAZOP), Layers of Protection Analysis (LOPA). | Green chemistry principles, Life Cycle Assessment (LCA), renewable energy integration. |

Defining Process Safety in Chemical Engineering

Process safety in chemical engineering refers to the systematic management of hazards to prevent accidents, such as fires, explosions, and toxic releases, ensuring the protection of people, environment, and assets. It encompasses risk assessment, implementation of safety systems, and adherence to regulatory standards like OSHA and EPA guidelines. Process sustainability, by contrast, integrates environmental stewardship, resource efficiency, and long-term operational viability, focusing on reducing the ecological footprint of chemical processes while maintaining safety protocols.

Understanding Process Sustainability Principles

Process sustainability principles emphasize the efficient use of resources, minimizing environmental impact, and promoting long-term viability in industrial operations. These principles integrate lifecycle assessment, waste reduction, and energy efficiency to ensure processes support ecological balance and social responsibility. Understanding process sustainability involves aligning operational goals with environmental stewardship, economic viability, and regulatory compliance to achieve holistic industrial resilience.

Core Objectives: Safety vs. Sustainability

Process safety aims to prevent accidents, hazards, and exposure risks within industrial operations, ensuring the protection of workers, equipment, and the environment. Process sustainability focuses on long-term environmental impact, resource efficiency, and minimizing waste to support ecological balance and corporate responsibility. While safety prioritizes immediate hazard control, sustainability emphasizes continuous improvement in energy use, emissions reduction, and sustainable materials management.

Regulatory Requirements for Safety and Sustainability

Process safety regulations primarily mandate hazard identification, risk assessment, and implementation of engineering controls to prevent accidents and protect workers, governed by standards such as OSHA's Process Safety Management (PSM) and EPA's Risk Management Plan (RMP). Process sustainability regulations emphasize minimizing environmental impact, resource efficiency, and long-term operational viability, guided by frameworks like the ISO 14001 Environmental Management System and the UN Sustainable Development Goals. Compliance with safety regulations ensures operational risk reduction, while sustainability mandates promote regulatory adherence to environmental stewardship and corporate responsibility.

Risk Management Strategies in Both Domains

Process safety emphasizes identifying, assessing, and mitigating risks to prevent accidents, equipment failures, and hazardous releases, utilizing strategies like hazard analysis, safety instrumentation, and emergency response planning. Process sustainability integrates risk management by addressing environmental, social, and economic impacts through lifecycle assessments, resource efficiency improvements, and waste reduction measures. Both domains employ continuous monitoring, data analytics, and regulatory compliance to enhance decision-making and ensure long-term operational integrity and resilience.

Lifecycle Assessment: Safety and Sustainability Perspectives

Lifecycle assessment (LCA) in process safety evaluates hazard identification, risk reduction, and accident prevention throughout the entire process lifecycle to protect human health and the environment. In contrast, process sustainability-based LCA emphasizes resource efficiency, emissions reduction, and environmental impact minimization from raw material extraction to end-of-life disposal. Integrating safety and sustainability perspectives in LCA enables comprehensive decision-making that balances risk mitigation with long-term environmental stewardship.

Integration Challenges: Balancing Safety and Sustainability

Integrating process safety and process sustainability involves managing conflicting goals such as hazard mitigation and environmental impact reduction. Challenges arise in aligning safety protocols that prevent accidents with sustainable practices aimed at resource efficiency and emissions reduction. Effective integration requires multidisciplinary approaches to optimize risk control measures while minimizing ecological footprints throughout the process lifecycle.

Technological Innovations for Safer, Sustainable Processes

Technological innovations in process safety, such as advanced sensors and AI-driven monitoring systems, enable real-time hazard detection and risk mitigation, significantly reducing industrial accidents. In process sustainability, innovations like green chemistry, energy-efficient reactors, and carbon capture technologies minimize environmental impact and resource consumption. Integrating these technologies creates safer, sustainable processes that optimize operational efficiency while protecting workers and the environment.

Case Studies: Aligning Process Safety with Sustainability Goals

Case studies demonstrate that integrating process safety with sustainability goals enhances operational resilience and reduces environmental impact. For example, BP's safety protocols during its sustainability initiatives helped prevent major incidents while lowering carbon emissions. These aligned strategies optimize resource use and promote long-term ecological and industrial stability.

Future Trends in Chemical Engineering: Safety Meets Sustainability

Process safety and process sustainability are converging priorities in chemical engineering, driven by innovations like digital twins, AI-powered risk assessments, and green chemistry. Future trends emphasize integrated systems that minimize environmental impact while maintaining operational safety, using real-time monitoring and predictive analytics to prevent accidents and reduce waste. Advances in catalyst development and energy-efficient processes contribute to sustainable practices without compromising process integrity or regulatory compliance.

Inherently Safer Design (ISD)

Inherently Safer Design (ISD) enhances process safety by eliminating hazards at the source while promoting process sustainability through minimized waste, reduced energy consumption, and safer chemical use.

Life Cycle Assessment (LCA)

Process safety ensures operational risk minimization, while process sustainability emphasizes environmental impact reduction through Life Cycle Assessment (LCA) to evaluate materials, energy use, and emissions across a product's entire life cycle.

Risk Assessment Matrix

The Risk Assessment Matrix is a critical tool in process safety for identifying and mitigating hazards, while in process sustainability it helps evaluate environmental and social risks to ensure long-term operational viability.

Green Chemistry Metrics

Process safety enhances hazard risk control while process sustainability, measured by green chemistry metrics like atom economy and E-factor, evaluates environmental and resource efficiency in chemical manufacturing.

Loss Prevention Systems

Loss Prevention Systems enhance process safety by minimizing hazards and accidents while contributing to process sustainability through reducing environmental impact and resource waste.

Sustainability Indices

Sustainability indices in process safety measure environmental impact, resource efficiency, and long-term operational resilience to balance safety protocols with sustainable development goals.

Hazard and Operability Study (HAZOP)

Hazard and Operability Study (HAZOP) primarily enhances process safety by systematically identifying hazards and operability issues, while process sustainability integrates these safety insights with environmental, social, and economic factors to promote long-term operational resilience.

Process Intensification

Process intensification enhances process safety by minimizing hazardous materials and conditions while promoting process sustainability through reduced energy consumption and waste generation.

Environmental Footprint Analysis

Process safety minimizes risks of accidents and hazardous releases, while process sustainability, assessed through Environmental Footprint Analysis, evaluates environmental impacts such as carbon emissions, resource consumption, and waste generation to promote eco-friendly operations.

Safety Integrity Level (SIL)

Safety Integrity Level (SIL) measures risk reduction in process safety systems while process sustainability emphasizes long-term environmental and operational resilience beyond SIL's safety focus.

Process safety vs Process sustainability Infographic

njnir.com

njnir.com