Filtration separates solids from liquids by passing the mixture through a porous medium, effectively trapping particles based on size and shape, ideal for handling large volumes of slurry with varied particle sizes. Centrifugation relies on centrifugal force to accelerate the sedimentation of particles, making it suitable for separating fine particles or emulsions and achieving faster separation in processes with low solid concentrations. Both techniques optimize separation efficiency, with filtration excelling in clarity and throughput and centrifugation offering precise solid-liquid phase differentiation in complex mixtures.

Table of Comparison

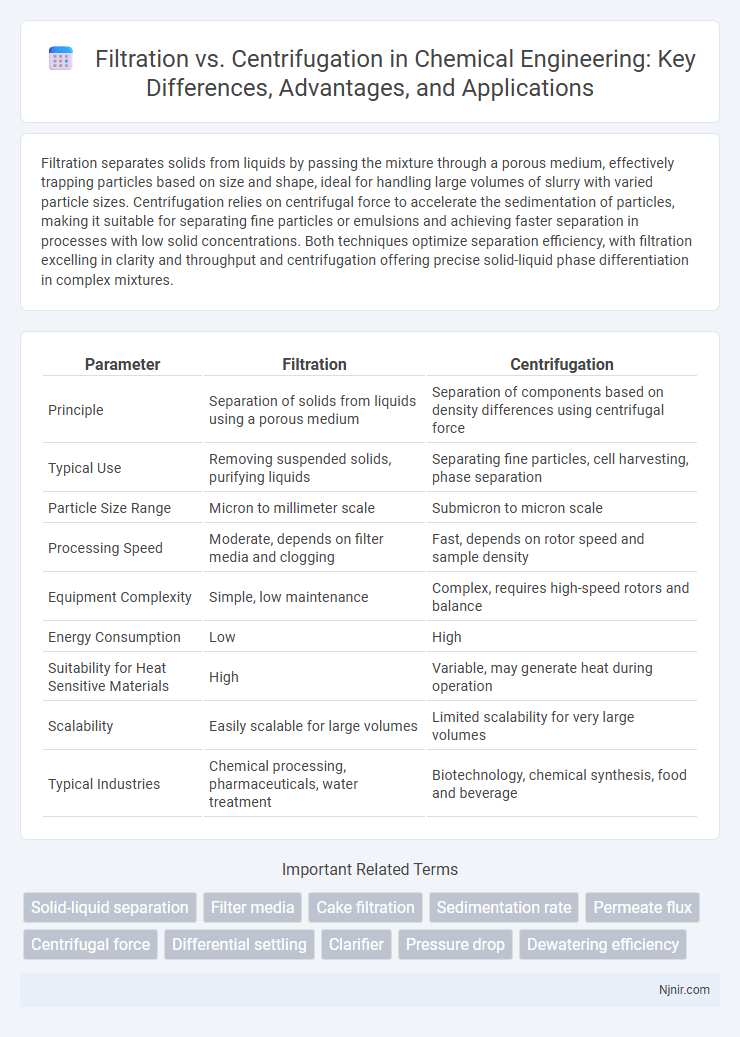

| Parameter | Filtration | Centrifugation |

|---|---|---|

| Principle | Separation of solids from liquids using a porous medium | Separation of components based on density differences using centrifugal force |

| Typical Use | Removing suspended solids, purifying liquids | Separating fine particles, cell harvesting, phase separation |

| Particle Size Range | Micron to millimeter scale | Submicron to micron scale |

| Processing Speed | Moderate, depends on filter media and clogging | Fast, depends on rotor speed and sample density |

| Equipment Complexity | Simple, low maintenance | Complex, requires high-speed rotors and balance |

| Energy Consumption | Low | High |

| Suitability for Heat Sensitive Materials | High | Variable, may generate heat during operation |

| Scalability | Easily scalable for large volumes | Limited scalability for very large volumes |

| Typical Industries | Chemical processing, pharmaceuticals, water treatment | Biotechnology, chemical synthesis, food and beverage |

Introduction to Solid-Liquid Separation Processes

Solid-liquid separation processes are essential in industries such as pharmaceuticals, wastewater treatment, and food processing, where efficient separation of solids from liquids impacts product quality and process efficiency. Filtration relies on a porous medium to retain solid particles while allowing the liquid to pass through, making it suitable for suspensions with larger or settled particles. Centrifugation uses centrifugal force to accelerate phase separation, effectively handling fine particles and emulsions that are challenging to separate by conventional gravitational methods.

Fundamental Principles of Filtration

Filtration relies on separating solids from liquids or gases by passing the mixture through a porous medium, which traps particles based on size exclusion. This process utilizes pressure differences to drive the fluid through a filter medium such as paper, cloth, or membranes, effectively capturing suspended solids while allowing the fluid to pass. Key variables in filtration include filter pore size, flow rate, and particle characteristics, which collectively determine the efficiency and clarity of the filtered output.

Operating Mechanism of Centrifugation

Centrifugation operates by applying centrifugal force to separate particles from a solution based on their size, shape, and density. During the process, the mixture is spun at high speeds, causing denser particles to move outward toward the container's bottom while lighter components remain closer to the center. This mechanism enables efficient separation of solids from liquids or different liquid phases without the need for filter media, distinguishing it from filtration methods.

Key Differences Between Filtration and Centrifugation

Filtration separates solids from liquids or gases using a porous medium, effectively removing particles based on size exclusion, whereas centrifugation relies on centrifugal force to separate components by density differences. Filtration is typically used for larger particle removal and clarification, while centrifugation is ideal for separating fine suspensions, emulsions, or precipitates that are difficult to filter. The efficiency of filtration depends on filter pore size and flow rate, contrasting with centrifugation speed and rotor design determining centrifugation performance.

Equipment Selection Criteria

Equipment selection for filtration prioritizes factors such as particle size, flow rate, and fluid viscosity to ensure efficient membrane or medium performance, while centrifugation equipment is chosen based on the density difference, rotor capacity, and centrifugal force requirements to achieve effective phase separation. Filtration systems often require considerations of filter pore size, pressure drops, and ease of cleaning, whereas centrifuges demand evaluation of speed, rotor type (fixed-angle or swinging-bucket), and maintenance complexity. The decision hinges on the nature of the material, throughput needs, and desired purity levels, balancing operational costs and process efficiency.

Efficiency and Performance Comparison

Filtration offers high efficiency in separating solid particles from liquids, especially for larger or coarse particles, by utilizing porous media that retain solids while allowing fluid flow. Centrifugation enhances performance by applying centrifugal force to accelerate the separation of fine or dense particles, achieving faster clarification and higher purity in suspensions. Efficiency in filtration depends on filter medium pore size and flow rate, whereas centrifugation efficiency is influenced by rotor speed, particle density difference, and centrifugal force applied.

Applications in Chemical Engineering Industries

Filtration and centrifugation are essential separation techniques in chemical engineering industries, each suited for specific applications based on particle size and phase differences. Filtration is widely used for separating solids from liquids in processes like wastewater treatment, catalyst recovery, and pharmaceutical production due to its efficiency in handling larger particulates. Centrifugation excels in separating fine particles and immiscible liquids in biotechnology, petrochemical refining, and nanomaterial synthesis, offering rapid phase separation and high precision in product purification.

Advantages and Limitations of Filtration

Filtration offers advantages such as simplicity, cost-effectiveness, and the ability to separate solids from liquids without requiring high energy input, making it ideal for processing large volumes. Limitations include slower processing times, potential filter clogging, and reduced efficiency with very fine particles or highly viscous fluids. Filter media selection is crucial to optimize performance and avoid contamination or loss of valuable materials.

Pros and Cons of Centrifugation

Centrifugation offers rapid and efficient separation of particles based on density, making it ideal for isolating cells, organelles, and biomolecules with high precision. However, it requires expensive equipment and skilled operation, and may cause sample damage due to high centrifugal forces. Unlike filtration, centrifugation is less effective for separating particles with similar densities and has limitations in handling large sample volumes continuously.

Future Trends and Innovations in Separation Technologies

Future trends in separation technologies highlight advancements in hybrid systems combining filtration and centrifugation to enhance efficiency and throughput. Innovations include membrane technologies with nanomaterials for selective filtration and high-speed centrifuges integrated with AI for real-time process optimization. Emerging applications leverage automated, continuous processing for industries such as pharmaceuticals, bioprocessing, and wastewater treatment, driving improved purity and reduced operational costs.

Solid-liquid separation

Filtration separates solids from liquids using a porous medium to trap particles, while centrifugation employs centrifugal force to accelerate sedimentation of solid particles in a liquid.

Filter media

Filter media in filtration separates solids from liquids by trapping particles within porous materials, whereas centrifugation relies on centrifugal force to separate particles based on density without using filter media.

Cake filtration

Cake filtration effectively separates solids from liquids by forming a porous cake layer on the filter medium, offering higher clarity and solids retention compared to centrifugation.

Sedimentation rate

Sedimentation rate in centrifugation is significantly faster than in filtration, enabling quicker separation of particles based on density differences.

Permeate flux

Permeate flux in filtration typically decreases gradually due to fouling, while centrifugation maintains higher flux rates by rapidly separating particles through centrifugal force.

Centrifugal force

Centrifugation utilizes centrifugal force to rapidly separate particles based on density differences, offering faster and more efficient separation compared to filtration.

Differential settling

Filtration separates solids from liquids by passing the mixture through a porous medium, while centrifugation accelerates differential settling by spinning samples at high speeds to rapidly separate components based on density differences.

Clarifier

Clarifiers use gravity-based sedimentation rather than mechanical separation like centrifugation, making filtration less effective in removing fine suspended solids compared to centrifugation.

Pressure drop

Filtration typically involves a higher pressure drop due to fluid passing through a porous medium, whereas centrifugation separates particles with minimal pressure drop by using centrifugal force.

Dewatering efficiency

Centrifugation offers higher dewatering efficiency than filtration by rapidly separating solids from liquids through centrifugal force, enabling faster moisture removal and reduced drying times.

Filtration vs Centrifugation Infographic

njnir.com

njnir.com