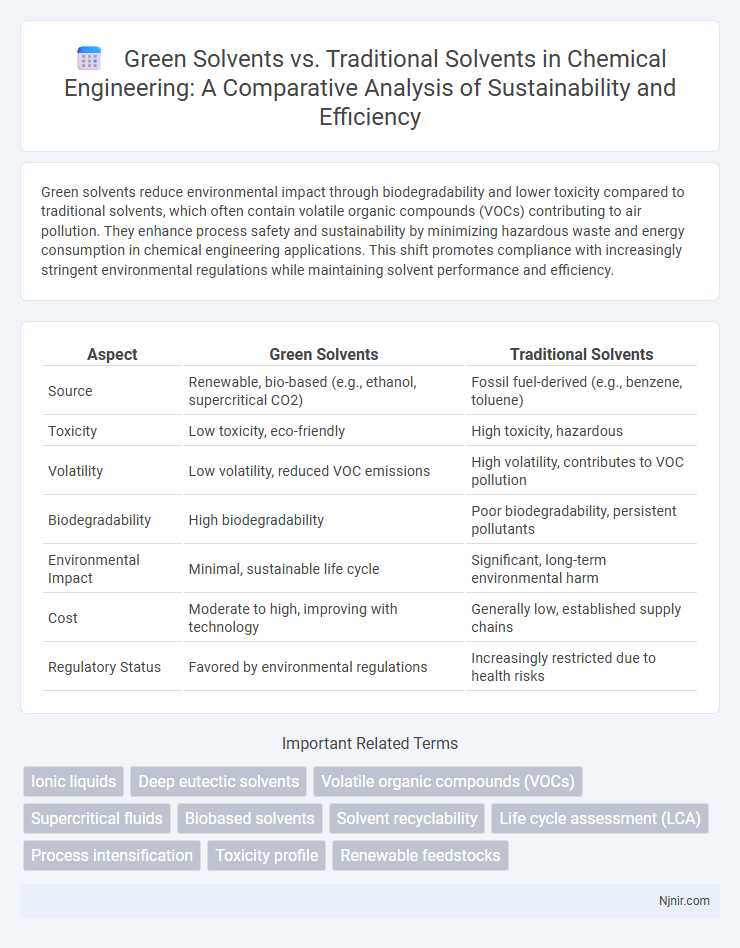

Green solvents reduce environmental impact through biodegradability and lower toxicity compared to traditional solvents, which often contain volatile organic compounds (VOCs) contributing to air pollution. They enhance process safety and sustainability by minimizing hazardous waste and energy consumption in chemical engineering applications. This shift promotes compliance with increasingly stringent environmental regulations while maintaining solvent performance and efficiency.

Table of Comparison

| Aspect | Green Solvents | Traditional Solvents |

|---|---|---|

| Source | Renewable, bio-based (e.g., ethanol, supercritical CO2) | Fossil fuel-derived (e.g., benzene, toluene) |

| Toxicity | Low toxicity, eco-friendly | High toxicity, hazardous |

| Volatility | Low volatility, reduced VOC emissions | High volatility, contributes to VOC pollution |

| Biodegradability | High biodegradability | Poor biodegradability, persistent pollutants |

| Environmental Impact | Minimal, sustainable life cycle | Significant, long-term environmental harm |

| Cost | Moderate to high, improving with technology | Generally low, established supply chains |

| Regulatory Status | Favored by environmental regulations | Increasingly restricted due to health risks |

Introduction to Green and Traditional Solvents

Green solvents are derived from renewable resources, offering lower toxicity and improved biodegradability compared to traditional solvents, which are primarily petrochemical-based and often pose environmental and health risks. Traditional solvents such as benzene, toluene, and xylene have been widely used due to their effective dissolving properties but contribute significantly to air pollution and hazardous waste. In contrast, green solvents include bio-based alcohols, esters, and supercritical fluids, promoting sustainable industrial processes and reducing ecological footprints.

Defining Green Solvents in Chemical Engineering

Green solvents in chemical engineering are environmentally friendly alternatives to traditional solvents, characterized by low toxicity, biodegradability, and minimal environmental impact. They are typically derived from renewable resources and designed to reduce volatile organic compound (VOC) emissions during chemical processes. The implementation of green solvents enhances sustainable manufacturing practices by improving safety and reducing hazardous waste generation.

Common Types of Traditional Solvents

Common types of traditional solvents include volatile organic compounds (VOCs) such as acetone, toluene, and xylene, widely used in industrial cleaning, paint thinning, and degreasing applications. These solvents are effective due to their strong dissolving power but pose environmental and health risks like toxicity and air pollution. In contrast, green solvents emphasize biodegradability and low toxicity, aiming to replace harmful traditional solvents in sustainable manufacturing processes.

Environmental Impact Comparison

Green solvents significantly reduce environmental impact by minimizing volatile organic compound (VOC) emissions and toxicity, leading to lower air and water pollution compared to traditional solvents. Traditional solvents often consist of petroleum-based chemicals that contribute to greenhouse gas emissions, ozone layer depletion, and soil contamination. The adoption of bio-based and biodegradable green solvents enhances sustainability by promoting safer waste disposal and reducing ecological damage.

Health and Safety Considerations

Green solvents, derived from renewable resources, typically exhibit lower toxicity and reduced environmental impact compared to traditional solvents, which are often volatile organic compounds (VOCs) linked to respiratory issues and carcinogenic risks. The reduced flammability and biodegradability of many green solvents enhance workplace safety and minimize hazardous waste generation in industrial processes. Prioritizing green solvents supports compliance with stringent occupational health regulations and fosters safer handling practices for chemical exposure.

Performance and Efficiency Metrics

Green solvents demonstrate comparable or superior solubility, selectivity, and reaction rates compared to traditional solvents, contributing to higher process efficiency and reduced waste generation. Metrics such as yield, purity, and energy consumption often favor green solvents due to their biodegradability, lower toxicity, and enhanced recyclability. Emphasizing solvent performance metrics like evaporation rate and viscosity reveals that green solvents can optimize industrial and pharmaceutical processes while minimizing environmental impact.

Economic Aspects of Solvent Selection

Green solvents reduce overall operational costs by minimizing hazardous waste disposal expenses and improving worker safety, which decreases healthcare and regulatory compliance costs. Traditional solvents often incur higher long-term expenditures due to toxicity, flammability, and environmental remediation requirements. Investing in green solvents can enhance economic efficiency by optimizing resource utilization and enabling eligibility for environmental incentives and subsidies.

Innovations in Green Solvent Technologies

Innovations in green solvent technologies include the development of bio-based solvents derived from renewable resources such as lignocellulosic biomass, offering reduced toxicity and enhanced biodegradability compared to traditional petroleum-based solvents. Advanced ionic liquids and deep eutectic solvents exhibit tunable physicochemical properties, enabling efficient solvation while minimizing environmental impact and facilitating solvent recovery. Emerging techniques incorporate green solvents in catalytic processes and nanoformulations, significantly improving reaction efficiency and product purity while lowering hazardous emissions.

Regulatory Trends and Compliance

Regulatory trends increasingly favor green solvents due to their lower toxicity, biodegradability, and reduced environmental impact compared to traditional solvents, prompting stricter compliance requirements under frameworks such as REACH and EPA's TSCA. Companies adopting bio-based solvents or water-based formulations benefit from streamlined approvals and enhanced market access as legislators emphasize sustainability and occupational safety. Compliance with evolving regulations drives innovation toward non-volatile organic compounds (VOCs) and minimized hazardous air pollutants (HAPs), promoting greener alternatives in industrial and commercial applications.

Future Perspectives and Industry Adoption

Green solvents, derived from renewable resources and exhibiting low toxicity, are rapidly gaining traction as sustainable alternatives to traditional solvents in chemical manufacturing and pharmaceuticals. Future perspectives emphasize advancements in bio-based solvent production, enhanced biodegradability, and regulatory incentives promoting eco-friendly solvents to minimize environmental impact. Industry adoption is accelerating due to increasing demand for green chemistry, cost-effectiveness in waste management, and compliance with stringent environmental regulations worldwide.

Ionic liquids

Ionic liquids, as green solvents, offer superior environmental benefits and enhanced chemical stability compared to traditional volatile organic solvents.

Deep eutectic solvents

Deep eutectic solvents outperform traditional solvents by offering biodegradable, non-toxic, and cost-effective alternatives that enhance green chemistry sustainability.

Volatile organic compounds (VOCs)

Green solvents significantly reduce volatile organic compound (VOC) emissions compared to traditional solvents, minimizing environmental pollution and health risks.

Supercritical fluids

Supercritical fluids, as green solvents, offer environmentally friendly extraction and reaction processes with reduced toxicity and improved efficiency compared to traditional organic solvents.

Biobased solvents

Biobased solvents, derived from renewable biomass, offer environmentally friendly alternatives to traditional solvents by reducing toxicity, volatility, and carbon emissions while maintaining effective solvency in industrial applications.

Solvent recyclability

Green solvents offer superior recyclability compared to traditional solvents, significantly reducing environmental impact and operational costs.

Life cycle assessment (LCA)

Life cycle assessment (LCA) reveals that green solvents significantly reduce environmental impacts across production, usage, and disposal stages compared to traditional solvents.

Process intensification

Green solvents enhance process intensification by improving mass transfer, reducing energy consumption, and minimizing waste compared to traditional solvents in chemical manufacturing.

Toxicity profile

Green solvents exhibit significantly lower toxicity profiles compared to traditional solvents, reducing environmental impact and health hazards in industrial applications.

Renewable feedstocks

Green solvents derived from renewable feedstocks minimize environmental impact and reduce reliance on finite fossil resources compared to traditional solvents.

Green solvents vs Traditional solvents Infographic

njnir.com

njnir.com