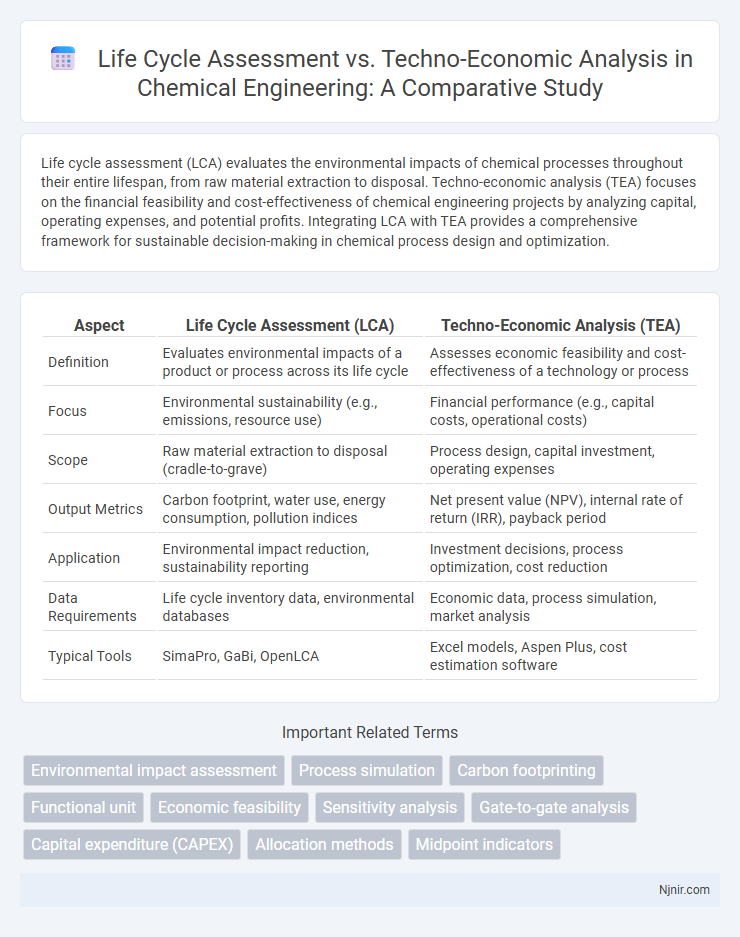

Life cycle assessment (LCA) evaluates the environmental impacts of chemical processes throughout their entire lifespan, from raw material extraction to disposal. Techno-economic analysis (TEA) focuses on the financial feasibility and cost-effectiveness of chemical engineering projects by analyzing capital, operating expenses, and potential profits. Integrating LCA with TEA provides a comprehensive framework for sustainable decision-making in chemical process design and optimization.

Table of Comparison

| Aspect | Life Cycle Assessment (LCA) | Techno-Economic Analysis (TEA) |

|---|---|---|

| Definition | Evaluates environmental impacts of a product or process across its life cycle | Assesses economic feasibility and cost-effectiveness of a technology or process |

| Focus | Environmental sustainability (e.g., emissions, resource use) | Financial performance (e.g., capital costs, operational costs) |

| Scope | Raw material extraction to disposal (cradle-to-grave) | Process design, capital investment, operating expenses |

| Output Metrics | Carbon footprint, water use, energy consumption, pollution indices | Net present value (NPV), internal rate of return (IRR), payback period |

| Application | Environmental impact reduction, sustainability reporting | Investment decisions, process optimization, cost reduction |

| Data Requirements | Life cycle inventory data, environmental databases | Economic data, process simulation, market analysis |

| Typical Tools | SimaPro, GaBi, OpenLCA | Excel models, Aspen Plus, cost estimation software |

Introduction to Life Cycle Assessment (LCA) and Techno-Economic Analysis (TEA)

Life Cycle Assessment (LCA) evaluates the environmental impacts associated with all stages of a product's life, from raw material extraction to disposal, providing a comprehensive environmental performance profile. Techno-Economic Analysis (TEA) assesses the economic viability and performance of technologies by modeling costs, investments, and operational expenses across the product or process lifecycle. Both LCA and TEA are essential tools for sustainable development, with LCA focusing on ecological metrics and TEA emphasizing financial feasibility and cost-effectiveness.

Fundamental Principles of LCA in Chemical Engineering

Life cycle assessment (LCA) in chemical engineering systematically evaluates environmental impacts associated with all stages of a product's life, from raw material extraction to disposal, emphasizing resource consumption, emissions, and waste generation. Fundamental principles of LCA include goal and scope definition, inventory analysis, impact assessment, and interpretation, ensuring comprehensive and transparent evaluation of sustainability metrics. In contrast, techno-economic analysis focuses primarily on financial feasibility and process optimization, often lacking the holistic environmental perspective inherent in LCA methodologies.

Core Concepts of TEA in Process Development

Techno-economic analysis (TEA) in process development quantifies the economic feasibility and performance of technologies by integrating process simulation data with cost estimation and financial metrics. Core concepts of TEA include capital expenditure (CAPEX), operational expenditure (OPEX), net present value (NPV), and internal rate of return (IRR), which collectively assess profitability and investment risks. Unlike life cycle assessment (LCA), which focuses on environmental impact and resource use, TEA emphasizes cost-effectiveness and economic viability throughout the technology development stages.

Key Differences Between LCA and TEA Methodologies

Life cycle assessment (LCA) evaluates environmental impacts across a product's entire life cycle, quantifying factors such as carbon footprint, resource depletion, and waste generation. Techno-economic analysis (TEA) focuses on the financial feasibility and economic performance of technologies by assessing capital costs, operating expenses, and return on investment. While LCA emphasizes sustainability metrics, TEA prioritizes cost-effectiveness and market viability, making them complementary tools in technology evaluation.

Integration of Environmental and Economic Metrics

Life cycle assessment (LCA) quantifies environmental impacts across product stages, providing critical data for sustainable decision-making. Techno-economic analysis (TEA) evaluates economic feasibility by assessing costs and benefits of technology implementation in detail. Integrating LCA and TEA enables comprehensive evaluation by combining environmental footprint metrics with economic performance, supporting balanced strategies for sustainable technology development.

Strengths and Limitations of LCA and TEA

Life Cycle Assessment (LCA) excels in evaluating environmental impacts across a product's entire life cycle, providing comprehensive insights into sustainability but often struggles with quantifying economic feasibility and market dynamics. Techno-Economic Analysis (TEA) focuses on detailed cost assessment and economic viability, enabling investment decisions and financial planning but typically lacks environmental impact depth and broader ecological considerations. Combining LCA and TEA offers a balanced approach, leveraging LCA's strength in environmental assessment with TEA's financial analysis, although challenges remain in integrating diverse datasets and methodologies.

Case Studies: LCA and TEA Applications in the Chemical Industry

Case studies in the chemical industry reveal that Life Cycle Assessment (LCA) effectively quantifies environmental impacts across product lifecycles, emphasizing carbon footprint reduction and resource efficiency. Techno-Economic Analysis (TEA) complements LCA by providing cost competitiveness and economic feasibility insights, focusing on capital expenditure, operating costs, and market viability for chemical processes. Integrating LCA and TEA results in comprehensive decision-making frameworks, optimizing both sustainability metrics and financial performance in process development and scale-up.

Challenges in Combining LCA and TEA Approaches

Combining Life Cycle Assessment (LCA) and Techno-Economic Analysis (TEA) presents challenges in aligning different system boundaries, functional units, and data requirements, complicating integrated assessments. Disparities in temporal and spatial scales between environmental and economic parameters hinder consistent interpretation and decision-making. Addressing these challenges requires harmonizing methodologies and improving data interoperability to enable comprehensive sustainability evaluations.

Future Trends: Digitalization and Advanced Modeling

Life cycle assessment and techno-economic analysis are increasingly integrating digitalization and advanced modeling techniques such as artificial intelligence, machine learning, and big data analytics to enhance accuracy and predictive capabilities. Digital twin technology and dynamic simulations enable real-time monitoring and optimization of environmental impacts and economic performance throughout product lifecycles. Future trends emphasize the convergence of these methods to support holistic sustainability decision-making with higher resolution, scalability, and efficiency.

Recommendations for Chemical Engineering Research and Practice

Life cycle assessment (LCA) and techno-economic analysis (TEA) provide complementary insights crucial for advancing chemical engineering research and practice. Integrating LCA with TEA enables comprehensive evaluation of environmental impacts alongside economic feasibility, guiding sustainable process design and innovation. Chemical engineers should prioritize developing standardized hybrid frameworks that combine these methodologies to optimize resource efficiency and reduce ecological footprints in industrial applications.

Environmental impact assessment

Life cycle assessment quantifies environmental impacts across product stages, while techno-economic analysis evaluates economic feasibility and performance, making LCA essential for comprehensive environmental impact assessment.

Process simulation

Process simulation enhances accuracy in both Life Cycle Assessment (LCA) and Techno-Economic Analysis (TEA) by modeling energy consumption, material flows, and emissions to optimize environmental impact and economic feasibility.

Carbon footprinting

Life cycle assessment provides a comprehensive evaluation of carbon footprint by analyzing environmental impacts across all stages of a product's life, while techno-economic analysis focuses on cost-effectiveness and economic feasibility with limited emphasis on carbon emissions.

Functional unit

Functional unit in Life Cycle Assessment quantifies environmental impacts per product function, while in Techno-Economic Analysis it measures economic performance relative to a defined output scale.

Economic feasibility

Techno-economic analysis provides a detailed evaluation of economic feasibility by integrating cost estimates and financial metrics, whereas life cycle assessment primarily focuses on environmental impacts throughout a product's life cycle and offers limited insight into economic viability.

Sensitivity analysis

Sensitivity analysis in life cycle assessment evaluates environmental impact variability due to input uncertainties, while in techno-economic analysis it quantifies the effect of economic and technical parameter fluctuations on project feasibility and cost-effectiveness.

Gate-to-gate analysis

Gate-to-gate analysis in life cycle assessment evaluates environmental impacts within specific production stages, while techno-economic analysis assesses the economic feasibility and performance costs of these same stages.

Capital expenditure (CAPEX)

Life cycle assessment evaluates environmental impacts throughout a product's lifespan, while techno-economic analysis quantifies Capital Expenditure (CAPEX) to assess financial feasibility and investment requirements.

Allocation methods

Life cycle assessment allocation methods prioritize environmental impact division across products or processes, while techno-economic analysis allocation focuses on cost and economic value distribution.

Midpoint indicators

Life cycle assessment utilizes midpoint indicators to quantify environmental impacts at specific stages, while techno-economic analysis primarily focuses on cost and performance metrics without detailing environmental midpoint impacts.

Life cycle assessment vs Techno-economic analysis Infographic

njnir.com

njnir.com