3D printing of catalysts offers precise control over catalyst architecture, enabling enhanced surface area and optimized mass transport compared to conventional synthesis methods. This advanced manufacturing technique allows for the creation of complex geometries and tailored porosity, which improves catalytic performance and reduces material waste. In contrast, traditional synthesis often involves less control over microstructure, resulting in lower efficiency and scalability challenges.

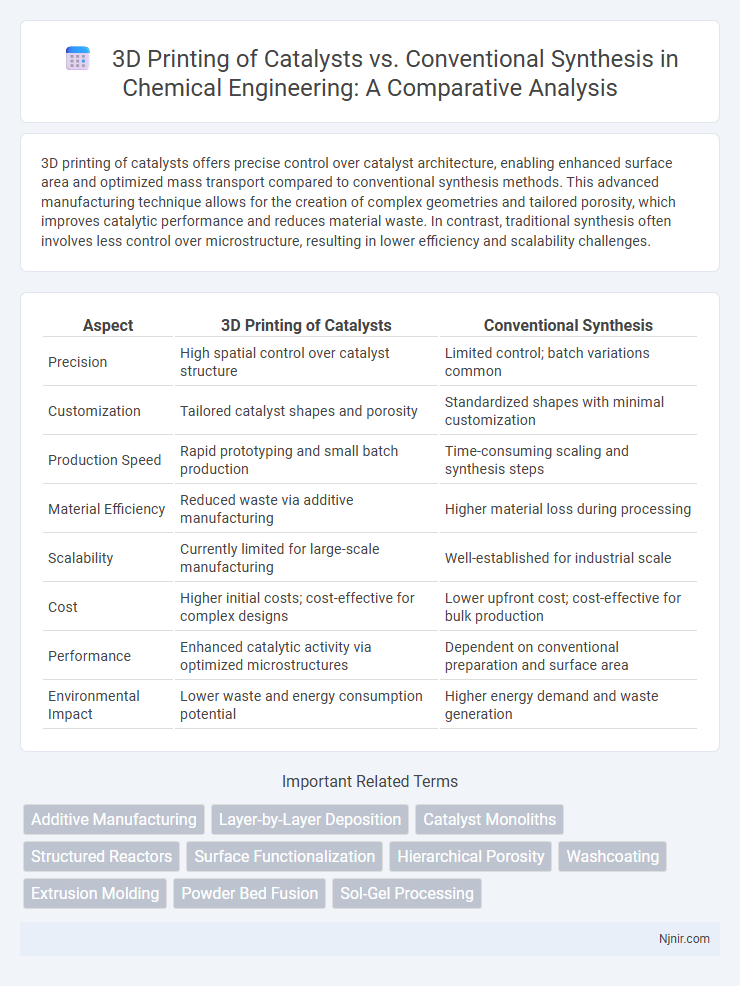

Table of Comparison

| Aspect | 3D Printing of Catalysts | Conventional Synthesis |

|---|---|---|

| Precision | High spatial control over catalyst structure | Limited control; batch variations common |

| Customization | Tailored catalyst shapes and porosity | Standardized shapes with minimal customization |

| Production Speed | Rapid prototyping and small batch production | Time-consuming scaling and synthesis steps |

| Material Efficiency | Reduced waste via additive manufacturing | Higher material loss during processing |

| Scalability | Currently limited for large-scale manufacturing | Well-established for industrial scale |

| Cost | Higher initial costs; cost-effective for complex designs | Lower upfront cost; cost-effective for bulk production |

| Performance | Enhanced catalytic activity via optimized microstructures | Dependent on conventional preparation and surface area |

| Environmental Impact | Lower waste and energy consumption potential | Higher energy demand and waste generation |

Introduction to Catalyst Fabrication Methods

Catalyst fabrication methods encompass a range of techniques including conventional synthesis such as impregnation, co-precipitation, and sol-gel processes, which rely on chemical reactions to produce active materials with controlled surface properties. 3D printing of catalysts introduces a novel approach by enabling precise control over catalyst geometry, pore structure, and spatial distribution of active sites, enhancing mass transfer and catalytic efficiency. This innovative fabrication method allows for customizable catalyst designs that are difficult to achieve through traditional techniques, potentially revolutionizing catalyst performance in various industrial applications.

Fundamentals of 3D Printing in Chemical Engineering

3D printing of catalysts enables precise control over catalyst geometry and porosity, enhancing mass transfer and active site accessibility compared to conventional synthesis methods. Techniques such as inkjet printing, extrusion-based printing, and stereolithography facilitate the design of hierarchical catalyst structures with tailored surface areas and mechanical stability. These advancements in additive manufacturing optimize catalyst performance and open new pathways for customizable, efficient chemical reactor designs in chemical engineering.

Overview of Conventional Catalyst Synthesis Techniques

Conventional catalyst synthesis techniques commonly involve methods such as impregnation, co-precipitation, sol-gel, and hydrothermal synthesis, each offering control over particle size, composition, and surface area. These methods typically require multiple steps including precursor preparation, deposition, drying, calcination, and reduction, which can be time-consuming and less flexible in tailoring catalyst architecture. Despite their widespread use, these techniques often struggle with reproducibility and scalability, limiting rapid optimization and customization compared to emerging 3D printing approaches.

Material Compatibility and Versatility

3D printing of catalysts offers superior material compatibility by enabling the precise layering of diverse materials, including polymers, metals, and ceramics, which is challenging in conventional synthesis methods. This additive manufacturing approach provides enhanced versatility in catalyst design, allowing for complex geometries and tailored porosity that improve catalytic performance and mass transport. Conventional synthesis often struggles with scalability and uniformity when incorporating multiple materials, limiting the range of functional catalysts achievable.

Structural Design and Geometric Precision

3D printing of catalysts enables unprecedented structural design and geometric precision by allowing the fabrication of complex architectures with controlled porosity and surface area, optimizing catalytic activity and mass transport. Unlike conventional synthesis methods, which rely on bulk material shaping and post-synthesis modification, 3D printing offers layer-by-layer construction at micrometer resolution, facilitating tailored active sites distribution and uniform catalyst morphology. This precise control over catalyst geometry enhances reaction efficiency and selectivity, making 3D printing a transformative approach in catalyst manufacturing.

Performance Metrics: Activity, Selectivity, and Stability

3D printing of catalysts offers precise control over catalyst architecture, significantly enhancing activity by optimizing surface area and active site accessibility compared to conventional synthesis. Selectivity improves through tailored pore structures that direct reactant flow and minimize side reactions, while stability is increased by precise distribution of active materials and robust support integration. Conventional synthesis methods often result in less uniform particle sizes and distributions, leading to variable performance metrics and decreased long-term operational durability.

Scalability and Industrial Implementation

3D printing of catalysts offers enhanced scalability through precise control over pore architecture and material distribution, enabling tailored catalyst designs that improve efficiency in industrial applications. Unlike conventional synthesis methods, which often involve batch processes with limited repeatability and scalability constraints, additive manufacturing facilitates continuous production and rapid prototyping. Industrial implementation benefits from reduced material waste and customization capabilities, accelerating catalyst development cycles and supporting large-scale manufacturing demands.

Environmental Impact and Sustainability

3D printing of catalysts significantly reduces waste and energy consumption compared to conventional synthesis methods by enabling precise material placement and minimizing the use of hazardous chemicals. This additive manufacturing technique promotes sustainability through the efficient recycling of materials and the ability to rapidly prototype catalysts, reducing the environmental footprint associated with large-scale batch production. Conventional synthesis often involves high temperatures, toxic solvents, and extensive purification steps, contributing to greater greenhouse gas emissions and resource depletion.

Cost Analysis and Economic Feasibility

3D printing of catalysts reduces material wastage and enables precise control over catalyst architecture, significantly lowering production costs compared to conventional synthesis methods that often involve multiple, energy-intensive steps and expensive templates. The scalability of 3D printing allows for rapid prototyping and customization, which enhances economic feasibility by minimizing time-to-market and reducing labor costs. Despite higher initial investment in 3D printing equipment, the long-term cost savings from improved catalyst efficiency and reduced raw material consumption make it a financially viable alternative for industrial applications.

Future Trends and Research Directions

3D printing of catalysts is revolutionizing catalyst design by enabling precise control over pore structure, composition, and geometry, leading to enhanced catalytic performance and reproducibility compared to conventional synthesis methods. Future trends emphasize the integration of advanced materials like metal-organic frameworks and nanocomposites tailored through additive manufacturing to optimize active site distribution and mass transport. Research directions focus on scalable multi-material printing techniques, machine learning-driven catalyst design, and in situ monitoring to accelerate the development of highly efficient, customizable catalysts for green energy and chemical processes.

Additive Manufacturing

Additive Manufacturing enables precise 3D printing of catalysts with controlled porosity and morphology, enhancing catalytic efficiency and reducing material waste compared to conventional synthesis methods.

Layer-by-Layer Deposition

Layer-by-layer deposition in 3D printing enables precise control over catalyst architecture and composition, surpassing the uniformity and flexibility limitations of conventional synthesis methods.

Catalyst Monoliths

3D printing of catalyst monoliths enables precise control over pore architecture and composition, significantly enhancing catalytic performance and reproducibility compared to conventional synthesis methods.

Structured Reactors

3D printing of catalysts enables precise fabrication of structured reactors with optimized mass transfer and surface area, outperforming conventional synthesis methods in catalytic efficiency and scalability.

Surface Functionalization

3D printing of catalysts enables precise surface functionalization with enhanced active site distribution and tunable porosity compared to conventional synthesis methods.

Hierarchical Porosity

3D printing of catalysts enables precise control over hierarchical porosity, enhancing mass transfer and catalytic efficiency compared to conventional synthesis methods.

Washcoating

3D printing of catalysts enables precise control over geometric washcoating patterns and thickness, enhancing surface area and catalytic efficiency compared to conventional synthesis methods.

Extrusion Molding

Extrusion molding in 3D printing enables precise catalyst structures with enhanced surface area and porosity compared to conventional synthesis, leading to improved catalytic efficiency and reproducibility.

Powder Bed Fusion

Powder Bed Fusion 3D printing enables precise control over catalyst geometry and porosity, enhancing surface area and reaction efficiency compared to conventional synthesis methods.

Sol-Gel Processing

3D printing of catalysts using Sol-Gel Processing enables precise control over porosity and morphology, significantly enhancing catalytic performance compared to conventional synthesis methods.

3D printing of catalysts vs Conventional synthesis Infographic

njnir.com

njnir.com