Aspen HYSYS offers advanced process simulation capabilities with robust thermodynamic models and extensive unit operation libraries, making it ideal for complex chemical engineering projects involving hydrocarbons and refinery processes. CHEMCAD provides flexible, user-friendly interfaces and customizable modules that support a wide range of chemical process simulations, including batch and continuous operations, with strong emphasis on cost-effectiveness and ease of use. Both software platforms integrate well with other engineering tools, but Aspen HYSYS tends to excel in large-scale, high-fidelity simulations while CHEMCAD is preferred for smaller, more iterative design and optimization tasks.

Table of Comparison

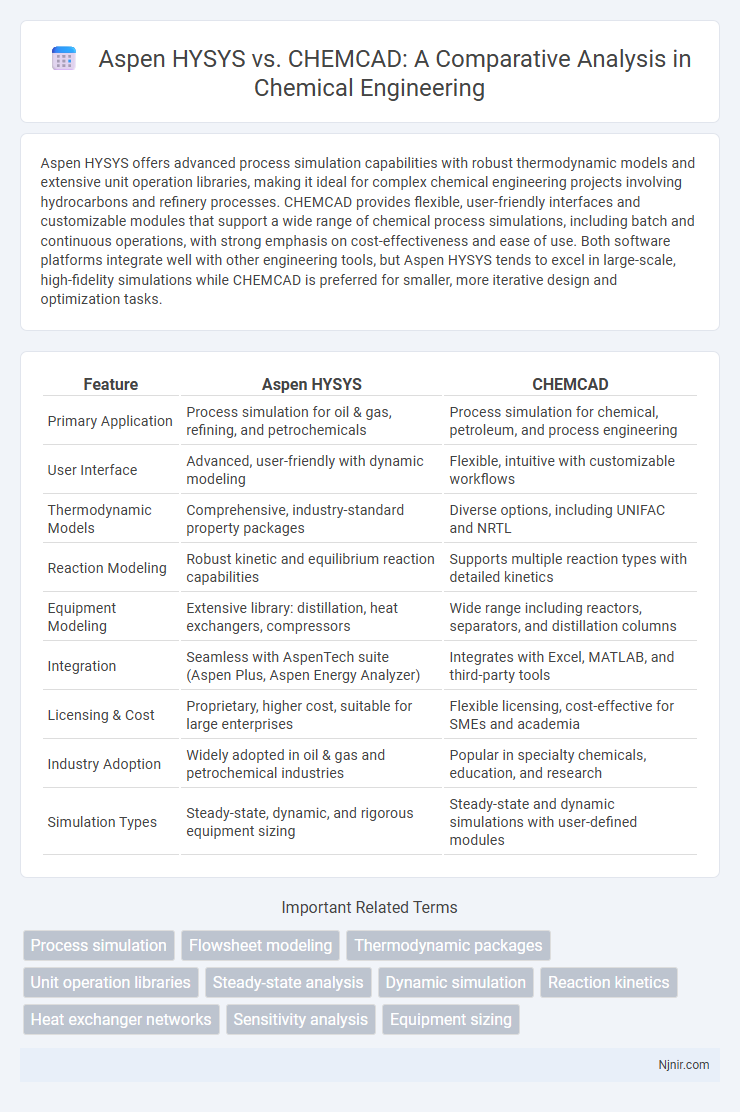

| Feature | Aspen HYSYS | CHEMCAD |

|---|---|---|

| Primary Application | Process simulation for oil & gas, refining, and petrochemicals | Process simulation for chemical, petroleum, and process engineering |

| User Interface | Advanced, user-friendly with dynamic modeling | Flexible, intuitive with customizable workflows |

| Thermodynamic Models | Comprehensive, industry-standard property packages | Diverse options, including UNIFAC and NRTL |

| Reaction Modeling | Robust kinetic and equilibrium reaction capabilities | Supports multiple reaction types with detailed kinetics |

| Equipment Modeling | Extensive library: distillation, heat exchangers, compressors | Wide range including reactors, separators, and distillation columns |

| Integration | Seamless with AspenTech suite (Aspen Plus, Aspen Energy Analyzer) | Integrates with Excel, MATLAB, and third-party tools |

| Licensing & Cost | Proprietary, higher cost, suitable for large enterprises | Flexible licensing, cost-effective for SMEs and academia |

| Industry Adoption | Widely adopted in oil & gas and petrochemical industries | Popular in specialty chemicals, education, and research |

| Simulation Types | Steady-state, dynamic, and rigorous equipment sizing | Steady-state and dynamic simulations with user-defined modules |

Overview of Aspen HYSYS and CHEMCAD

Aspen HYSYS offers comprehensive process simulation capabilities with strong focus on steady-state and dynamic modeling for oil and gas, refining, and petrochemical industries. CHEMCAD provides flexible modular design with customizable unit operations and user-friendly interface ideal for chemical process design, optimization, and thermal hydraulic calculations. Both platforms support rigorous thermodynamic models and extensive component databases, enabling precise process analysis and optimization across diverse chemical engineering applications.

User Interface and Workflow Comparison

Aspen HYSYS features a visually intuitive user interface with interconnected process flow diagrams that streamline simulation and optimization tasks, enhancing user efficiency in complex process design. CHEMCAD offers a customizable and modular workflow environment, enabling users to tailor their interface and process sequences to specific project needs, which improves flexibility and ease of navigation. Both platforms support drag-and-drop components and real-time data updates, but HYSYS excels in integrated process economics tools, while CHEMCAD prioritizes user-friendly batch processing and straightforward module access.

Simulation Capabilities and Accuracy

Aspen HYSYS excels in process simulation with advanced thermodynamic models and rigorous steady-state and dynamic simulations, providing high accuracy for oil and gas, refining, and chemical processes. CHEMCAD offers flexible modular simulation tools with strong customizability and ease of use, supporting a wide range of unit operations and thermodynamic methods for precise chemical process design. Both platforms deliver reliable simulation capabilities, but Aspen HYSYS is often preferred for complex hydrocarbon processing accuracy, while CHEMCAD is favored for versatility in diverse chemical industries.

Thermodynamic Models and Physical Properties

Aspen HYSYS offers a comprehensive selection of thermodynamic models, including Peng-Robinson, Soave-Redlich-Kwong, and NRTL, optimized for hydrocarbon processing and gas treating applications, ensuring accurate phase equilibrium and property predictions. CHEMCAD provides flexibility with advanced thermodynamic packages such as UNIQUAC, UNIFAC, and Electrolyte-NRTL, enabling precise modeling of complex liquid mixtures and electrolyte systems. Both simulators incorporate extensive physical property databases, but Aspen HYSYS excels in refinery and natural gas processing contexts, whereas CHEMCAD is preferred for specialty chemicals and custom thermodynamic model integration.

Process Optimization Features

Aspen HYSYS offers advanced process optimization features such as rigorous steady-state and dynamic simulation, integrated model predictive control, and detailed thermodynamic packages tailored for hydrocarbon processing industries. CHEMCAD provides flexible customization with its open architecture, enabling seamless integration of optimization algorithms and user-defined unit operations for diverse chemical processes. Both software platforms support multi-variable optimization and energy consumption reduction, but Aspen HYSYS excels in large-scale refinery optimization while CHEMCAD is preferred for smaller-scale, versatile process design.

Equipment Modeling and Libraries

Aspen HYSYS features an extensive equipment modeling library with detailed thermodynamic packages and dynamic simulation capabilities, supporting complex unit operations such as distillation, heat exchangers, and reactors. CHEMCAD offers flexible equipment models with a user-friendly interface and customizable libraries, enabling easy integration of proprietary or uncommon equipment types. Both platforms provide comprehensive material databases, but Aspen HYSYS emphasizes advanced process optimization with richer built-in industry-specific equipment models.

Integration with Other Engineering Tools

Aspen HYSYS offers robust integration capabilities with popular engineering platforms like AspenTech's suite and third-party process simulators, enhancing workflow automation and data consistency. CHEMCAD provides flexible API support and seamless connectivity with CAD, ERP, and lab information management systems, improving collaboration across engineering and project management teams. Both software solutions prioritize interoperability, but Aspen HYSYS excels in complex process integration, while CHEMCAD favors customizable interfaces for diverse engineering environments.

Customization and Scripting Options

Aspen HYSYS offers extensive customization through its COM-based scripting interface and supports automation via Visual Basic for Applications (VBA), enabling process engineers to create tailored simulation tools and workflows. CHEMCAD provides versatile scripting capabilities using its built-in scripting language, allowing users to automate design tasks and integrate with external applications for customized process modeling. Both platforms facilitate enhanced process simulation control, but Aspen HYSYS is favored for its robust integration with third-party software and advanced custom module development.

Licensing, Pricing, and Support

Aspen HYSYS offers flexible licensing options, including node-locked and floating licenses, with pricing typically higher due to its comprehensive capabilities and industry reputation, while CHEMCAD provides more affordable licensing schemes suitable for small to mid-sized enterprises. Both software vendors offer robust customer support with AspenTech providing extensive global technical assistance and training programs, whereas Chemstations focuses on personalized support and quicker response times for CHEMCAD users. Pricing models for Aspen HYSYS often involve annual maintenance fees, whereas CHEMCAD licenses include options for perpetual and subscription licenses, making it a cost-effective choice for diverse budget requirements.

Industry Applications and User Feedback

Aspen HYSYS is extensively utilized in the oil and gas industry for process simulation and optimization, favored for its robust capabilities in gas processing and refinery operations. CHEMCAD finds strong application in chemical manufacturing and pharmaceuticals, appreciated for its flexible, user-friendly interface and customization features. User feedback highlights Aspen HYSYS's advanced thermodynamic models and steady-state simulation accuracy, while CHEMCAD receives praise for its ease of use and cost-effective licensing for small to mid-sized plants.

Process simulation

Aspen HYSYS excels in dynamic process simulation with advanced fluid property modeling and refinery applications, while CHEMCAD offers flexible and user-friendly steady-state simulation ideal for chemical and batch process design.

Flowsheet modeling

Aspen HYSYS offers advanced dynamic flowsheet modeling with extensive thermodynamic libraries and industry-specific unit operations, while CHEMCAD provides user-friendly, flexible flowsheet simulation tailored for rapid customization and integration in process design.

Thermodynamic packages

Aspen HYSYS offers extensive thermodynamic package options including Peng-Robinson, Soave-Redlich-Kwong, and NRTL models, while CHEMCAD provides a diverse range with UNIQUAC, Electrolyte NRTL, and extended Peng-Robinson for advanced vapor-liquid equilibrium and electrolyte system simulations.

Unit operation libraries

Aspen HYSYS offers an extensive and industry-standard unit operation library optimized for hydrocarbon processing, while CHEMCAD provides a versatile and customizable unit operation library suitable for diverse chemical engineering applications.

Steady-state analysis

Aspen HYSYS offers advanced steady-state analysis with comprehensive thermodynamic models and rigorous unit operation simulations, while CHEMCAD provides flexible steady-state capabilities tailored for customizable process flowsheets and integrated unit operations.

Dynamic simulation

Aspen HYSYS offers advanced dynamic simulation capabilities with integrated control design and rigorous equipment modeling, whereas CHEMCAD provides flexible dynamic simulation suitable for custom process control and operator training but with less built-in industry-specific libraries.

Reaction kinetics

Aspen HYSYS offers advanced reaction kinetics modeling with extensive reactor type options and detailed property methods, while CHEMCAD provides flexible kinetic modeling with user-defined reactions and strong integration for custom reaction mechanisms.

Heat exchanger networks

Aspen HYSYS offers advanced heat exchanger network synthesis with integrated optimization and dynamic simulation, while CHEMCAD provides flexible heat exchanger design tools emphasizing customizable network configurations and cost analysis.

Sensitivity analysis

Aspen HYSYS provides advanced sensitivity analysis tools with integrated process simulation capabilities for dynamic scenario evaluation, while CHEMCAD offers customizable sensitivity modules emphasizing user-defined parameter variation for comprehensive process optimization.

Equipment sizing

Aspen HYSYS excels in dynamic equipment sizing with advanced process simulation and rigorous thermodynamic models, while CHEMCAD offers flexible, user-friendly equipment sizing tools ideal for steady-state design and customization.

Aspen HYSYS vs CHEMCAD Infographic

njnir.com

njnir.com