Aspen Plus excels in complex simulation of chemical processes with specialized unit operation models and rigorous thermodynamic property packages, making it ideal for research and development in chemical engineering. HYSYS offers user-friendly process modeling and dynamic simulation capabilities, which are widely preferred for steady-state and transient analysis in oil and gas production and refinery operations. Both software tools integrate advanced process optimization features but differ in interface and industry focus, influencing the choice based on project requirements and sector-specific applications.

Table of Comparison

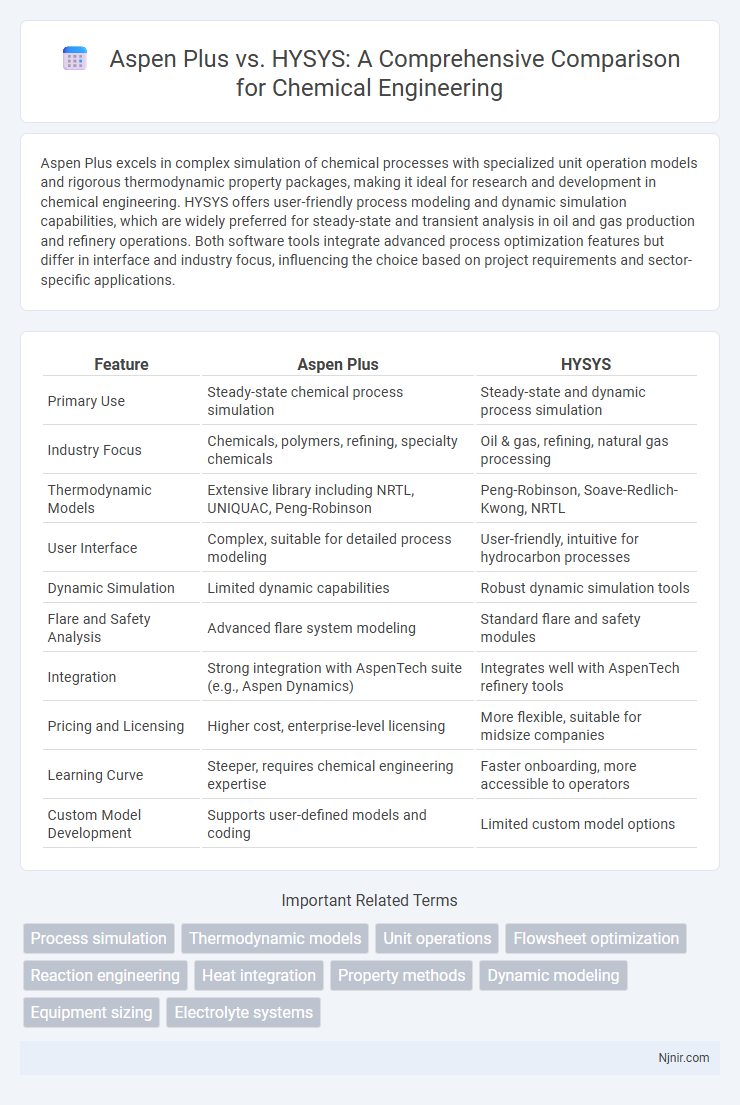

| Feature | Aspen Plus | HYSYS |

|---|---|---|

| Primary Use | Steady-state chemical process simulation | Steady-state and dynamic process simulation |

| Industry Focus | Chemicals, polymers, refining, specialty chemicals | Oil & gas, refining, natural gas processing |

| Thermodynamic Models | Extensive library including NRTL, UNIQUAC, Peng-Robinson | Peng-Robinson, Soave-Redlich-Kwong, NRTL |

| User Interface | Complex, suitable for detailed process modeling | User-friendly, intuitive for hydrocarbon processes |

| Dynamic Simulation | Limited dynamic capabilities | Robust dynamic simulation tools |

| Flare and Safety Analysis | Advanced flare system modeling | Standard flare and safety modules |

| Integration | Strong integration with AspenTech suite (e.g., Aspen Dynamics) | Integrates well with AspenTech refinery tools |

| Pricing and Licensing | Higher cost, enterprise-level licensing | More flexible, suitable for midsize companies |

| Learning Curve | Steeper, requires chemical engineering expertise | Faster onboarding, more accessible to operators |

| Custom Model Development | Supports user-defined models and coding | Limited custom model options |

Overview of Aspen Plus and HYSYS

Aspen Plus and HYSYS are leading process simulation software widely used in chemical engineering for modeling and optimizing industrial processes. Aspen Plus excels in steady-state simulation of various chemical processes, offering extensive thermodynamic property databases and rigorous unit operation models, making it ideal for complex chemical reactions and separation processes. HYSYS specializes in dynamic and steady-state simulations with a strong focus on hydrocarbon processing, integrated refinery operations, and natural gas processing, providing advanced tools for process design and operations optimization.

Key Features Comparison

Aspen Plus excels in complex chemical process simulation with extensive thermodynamic models and rigorous steady-state and dynamic analysis, making it ideal for detailed process design and optimization. HYSYS specializes in oil and gas applications, offering strong capabilities in steady-state and dynamic simulation, process modeling, and equipment sizing tailored for hydrocarbon processing industries. Both software provide robust unit operation libraries, sensitivity analysis, and advanced optimization tools, but Aspen Plus offers greater flexibility for specialty chemical processes while HYSYS integrates seamlessly with upstream and downstream hydrocarbon process workflows.

User Interface and Workflow

Aspen Plus offers a highly intuitive user interface with drag-and-drop process flow diagramming, making it efficient for complex simulation setup in chemical processing. HYSYS provides a streamlined, user-friendly workflow particularly suited for oil and gas applications, featuring dynamic simulation capabilities and real-time process monitoring. Both software tools enhance engineering productivity, but Aspen Plus excels in detailed chemical reactions modeling, while HYSYS is optimized for steady-state and dynamic simulations in hydrocarbon processing.

Process Modeling Capabilities

Aspen Plus excels in rigorous process modeling with comprehensive thermodynamic packages and a wide range of unit operation models, making it ideal for complex chemical processes and steady-state simulations. HYSYS offers robust dynamic process simulation capabilities and is particularly strong in oil and gas, refining, and natural gas processing industries. Both platforms support detailed heat and material balance calculations, but Aspen Plus provides deeper flexibility in process design optimization and custom modeling.

Thermodynamic Packages and Property Methods

Aspen Plus and HYSYS feature distinct thermodynamic packages tailored for process simulation; Aspen Plus excels with a broad range of rigorous property methods such as NRTL, UNIQUAC, and Electrolyte Non-Random Two-Liquid (eNRTL), ideal for complex chemical processes and phase equilibrium. HYSYS primarily emphasizes hydrocarbon and petroleum-based simulations with property methods like Peng-Robinson, Soave-Redlich-Kwong (SRK), and API correlations optimized for natural gas and refinery processes. Selection between Aspen Plus and HYSYS depends on the simulation focus, with Aspen Plus favored for detailed chemical system thermodynamics and HYSYS preferred for steady-state hydrocarbon process modeling with fast and efficient property estimations.

Application Areas in Chemical Engineering

Aspen Plus excels in steady-state process simulation, offering robust capabilities for petrochemical, polymer, and refining industries, making it ideal for complex chemical reactions and separations design. HYSYS is widely used in oil and gas processing, natural gas treatment, and pipeline modeling due to its dynamic simulation strengths and detailed thermodynamic property packages. Both software tools integrate process optimization and sensitivity analysis, but their application areas diverge with Aspen Plus favoring detailed chemical process design and HYSYS focusing on hydrocarbon processing and dynamic plant operations.

Simulation Accuracy and Reliability

Aspen Plus and HYSYS are renowned process simulation tools, with Aspen Plus excelling in detailed chemical process modeling and thermodynamic accuracy, especially for complex reactions and steady-state analysis. HYSYS offers superior dynamic simulation capabilities and is widely favored in oil and gas industries for its reliable handling of hydrocarbon processes and transient operations. Both software deliver high reliability, but Aspen Plus is preferred for precision in chemical reaction engineering while HYSYS dominates in dynamic process simulation and real-time plant performance optimization.

Integration with Other Engineering Tools

Aspen Plus offers extensive integration capabilities with MATLAB, Excel, and various database systems, enhancing data exchange and process optimization workflows. HYSYS supports seamless interoperability with Aspen InfoPlus.21 (IP.21) and AVEVA's engineering suite, facilitating real-time process data analysis and collaboration. Both simulators provide APIs and COM automation for custom tool integration, but Aspen Plus excels in advanced data handling and simulation customization.

Cost and Licensing Considerations

Aspen Plus typically requires higher initial licensing fees and annual maintenance costs compared to HYSYS, reflecting its extensive capabilities in complex chemical process simulations. HYSYS offers more flexible licensing options, including standalone and enterprise versions, often preferred in hydrocarbon processing industries for cost-effective scalability. Both software solutions may include additional module costs, so budgeting should consider long-term expenses related to upgrades, technical support, and concurrent user licenses.

Industry Adoption and User Community

Aspen Plus is widely adopted in the chemical process industry with a strong user community focused on complex reactions and separation processes, supporting extensive academic and industrial applications. HYSYS dominates the oil and gas, refining, and natural gas processing sectors, boasting a robust user base that values dynamic simulation capabilities and steady-state process optimization. Both platforms have comprehensive training resources and active forums that facilitate knowledge sharing and continuous software improvement among professionals.

Process simulation

Aspen Plus excels in rigorous chemical process simulations with extensive thermodynamic models, while HYSYS offers user-friendly interface and strong capabilities in oil and gas process simulations.

Thermodynamic models

Aspen Plus offers a broader range of advanced thermodynamic models including NRTL, UNIQUAC, and electrolyte theories for complex phase equilibria, while HYSYS emphasizes robust, industry-standard models like Peng-Robinson and Soave-Redlich-Kwong optimized for hydrocarbon processing simulations.

Unit operations

Aspen Plus offers extensive unit operation models for chemical process simulation, while HYSYS specializes in dynamic and steady-state unit operation modeling primarily for oil and gas production and refining processes.

Flowsheet optimization

Aspen Plus offers advanced rigorous modeling and detailed reactions ideal for complex flowsheet optimization, while HYSYS excels in steady-state and dynamic simulation with user-friendly interfaces for process design and operational flexibility.

Reaction engineering

Aspen Plus offers advanced reaction engineering capabilities with detailed kinetics and comprehensive reactor models, whereas HYSYS emphasizes process simulation with simplified reaction modules tailored for hydrocarbon processing.

Heat integration

Aspen Plus offers advanced heat integration tools for rigorous energy optimization, while HYSYS excels in dynamic simulation and steady-state process integration for flexible heat exchanger network design.

Property methods

Aspen Plus offers a wider range of advanced property methods including UNIFAC, NRTL, and NRTL-H, while HYSYS primarily focuses on conventional property methods like Peng-Robinson and Soave-Redlich-Kwong tailored for hydrocarbon processing.

Dynamic modeling

Aspen Plus offers limited dynamic modeling capabilities primarily for steady-state simulations, whereas HYSYS provides advanced dynamic modeling features essential for real-time process control and transient analysis in chemical engineering.

Equipment sizing

Aspen Plus offers advanced equipment sizing with detailed thermodynamic models and customization options, while HYSYS excels in dynamic simulation and straightforward sizing for oil and gas processing equipment.

Electrolyte systems

Aspen Plus offers advanced electrolyte system modeling with comprehensive thermodynamic property methods and customized electrolyte databases, while HYSYS provides user-friendly interface and efficient simulation for common electrolytes but with less extensive electrolyte-specific options.

Aspen Plus vs HYSYS Infographic

njnir.com

njnir.com