Bioethanol and biodiesel are prominent biofuels derived from renewable biological sources, each offering distinct advantages in chemical engineering applications. Bioethanol, primarily produced through the fermentation of sugars from crops like corn and sugarcane, is widely used as an oxygenate additive in gasoline to reduce emissions and enhance octane rating. Biodiesel, synthesized via transesterification of vegetable oils or animal fats, serves as a biodegradable alternative to petroleum diesel, providing superior lubrication and lower particulate emissions in diesel engines.

Table of Comparison

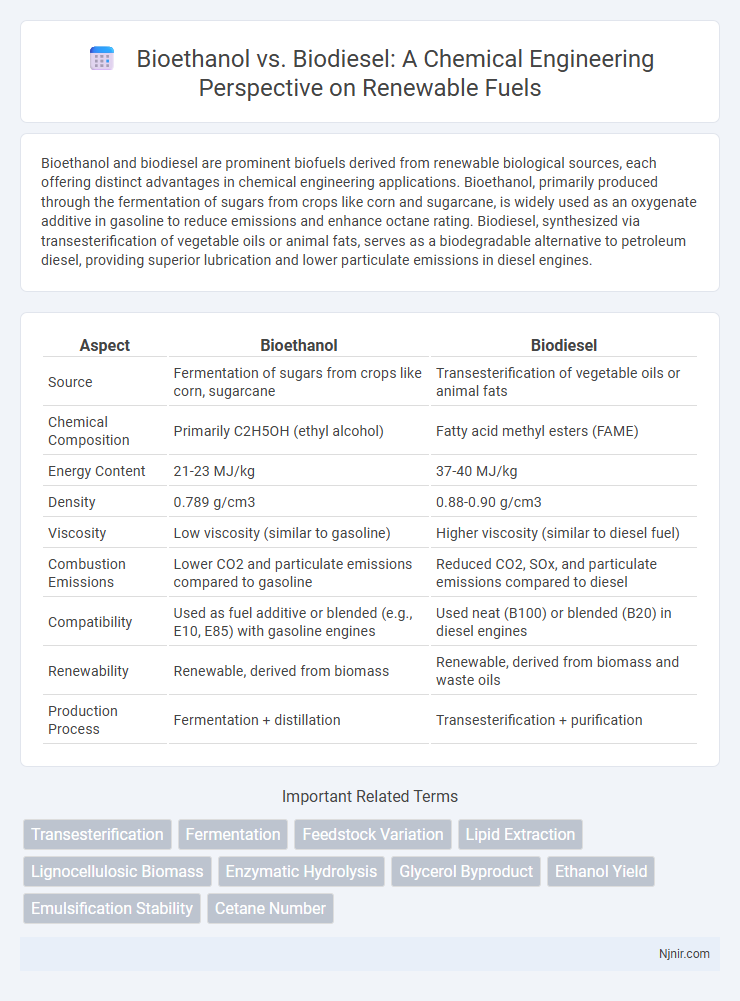

| Aspect | Bioethanol | Biodiesel |

|---|---|---|

| Source | Fermentation of sugars from crops like corn, sugarcane | Transesterification of vegetable oils or animal fats |

| Chemical Composition | Primarily C2H5OH (ethyl alcohol) | Fatty acid methyl esters (FAME) |

| Energy Content | 21-23 MJ/kg | 37-40 MJ/kg |

| Density | 0.789 g/cm3 | 0.88-0.90 g/cm3 |

| Viscosity | Low viscosity (similar to gasoline) | Higher viscosity (similar to diesel fuel) |

| Combustion Emissions | Lower CO2 and particulate emissions compared to gasoline | Reduced CO2, SOx, and particulate emissions compared to diesel |

| Compatibility | Used as fuel additive or blended (e.g., E10, E85) with gasoline engines | Used neat (B100) or blended (B20) in diesel engines |

| Renewability | Renewable, derived from biomass | Renewable, derived from biomass and waste oils |

| Production Process | Fermentation + distillation | Transesterification + purification |

Introduction to Bioethanol and Biodiesel

Bioethanol is an alcohol-based biofuel produced primarily through the fermentation of sugars derived from crops such as sugarcane, corn, and wheat, making it a renewable alternative to gasoline. Biodiesel is a renewable diesel substitute synthesized from vegetable oils, animal fats, or recycled cooking oils through a chemical process called transesterification, compatible with conventional diesel engines. Both bioethanol and biodiesel contribute to reducing greenhouse gas emissions and reliance on fossil fuels in the transportation sector.

Feedstock Sources and Availability

Bioethanol is primarily produced from carbohydrate-rich feedstocks such as sugarcane, corn, and wheat, making it widely available in regions with extensive agricultural crop production. Biodiesel is derived from lipid-rich feedstocks including vegetable oils like soybean, rapeseed, and palm oil, as well as animal fats, which influence its availability based on local oilseed cultivation and livestock industries. The choice between bioethanol and biodiesel feedstocks significantly impacts production scalability and sustainability depending on regional agricultural resources.

Production Processes and Technologies

Bioethanol is primarily produced through the fermentation of sugar- or starch-rich biomass such as corn, sugarcane, or cellulosic materials using yeast or bacteria, whereas biodiesel is synthesized via transesterification, where vegetable oils or animal fats react with an alcohol like methanol in the presence of a catalyst. Advanced technologies for bioethanol production include enzymatic hydrolysis and genetically engineered microorganisms that enhance cellulose breakdown and fermentation efficiency, while biodiesel production has seen innovations in catalyst development and continuous flow processes to improve yield and reduce reaction times. Both fuels utilize renewable feedstocks but differ significantly in biochemical conversion pathways and processing equipment, influencing their energy balance and scalability for sustainable biofuel production.

Chemical Properties and Composition

Bioethanol is a renewable alcohol primarily composed of ethanol (C2H5OH) molecules, characterized by its polar hydroxyl group, which enhances its solubility in water and facilitates combustion with lower emissions of particulate matter. Biodiesel consists mainly of fatty acid methyl esters (FAME) derived from triglycerides found in vegetable oils or animal fats, featuring long hydrocarbon chains that impart higher energy density and better lubrication properties compared to bioethanol. Chemical differences in polarity and molecular structure between bioethanol and biodiesel influence their combustion characteristics, viscosity, and compatibility with diesel engines versus gasoline engines.

Energy Balance and Yield Efficiency

Bioethanol typically demonstrates a positive energy balance with yields averaging around 4500 liters per hectare from feedstocks like sugarcane, while biodiesel offers higher energy density and yield efficiency, producing approximately 2200 liters per hectare from crops such as soybean or palm oil. Energy balance for biodiesel often exceeds 3.0, indicating it generates over three units of energy per unit of fossil energy invested, whereas bioethanol's energy balance varies between 1.2 and 8.3 depending on the feedstock and production process. Yield efficiency and net energy gain make biodiesel more energy-dense, but bioethanol delivers superior volumetric yields and faster crop rotation cycles, influencing their respective sustainability profiles in biofuel production.

Environmental Impact and Emissions

Bioethanol, derived primarily from sugarcane or corn, significantly reduces greenhouse gas emissions by up to 50% compared to conventional gasoline due to its renewable biomass origin and faster carbon cycle. Biodiesel, produced from vegetable oils or animal fats, lowers carbon monoxide and particulate matter emissions by approximately 40-60%, offering superior biodegradability and reduced toxicity in aquatic environments. Both biofuels contribute to lowering fossil fuel dependence, but biodiesel's higher energy density and better lubricity result in more efficient engine performance and fewer harmful nitrogen oxide emissions relative to bioethanol.

Engine Compatibility and Performance

Bioethanol is compatible with gasoline engines, often requiring minor modifications such as fuel system adjustments due to its higher oxygen content and lower energy density compared to gasoline. Biodiesel works well with diesel engines, offering improved lubricity and higher cetane numbers, which enhance combustion efficiency and reduce engine wear. Performance-wise, bioethanol may reduce fuel economy due to its lower energy content, while biodiesel typically maintains or slightly improves fuel economy and produces lower emissions of particulates and hydrocarbons.

Economic Considerations and Market Trends

Bioethanol production benefits from abundant feedstocks like corn and sugarcane, resulting in lower production costs compared to biodiesel, which relies heavily on vegetable oils such as soybean and palm oil with fluctuating prices. Market trends indicate rising bioethanol demand driven by its compatibility with existing gasoline infrastructure and government incentives promoting renewable fuels. Biodiesel markets experience volatility due to feedstock supply constraints and the need for blending mandates to expand adoption, impacting its economic competitiveness.

Sustainability and Lifecycle Assessment

Bioethanol and biodiesel both offer renewable energy solutions with distinct sustainability profiles and lifecycle assessments. Bioethanol, primarily produced from sugarcane, corn, or cellulosic materials, demonstrates lower greenhouse gas emissions compared to fossil fuels, but its sustainability can be challenged by land use changes and water consumption. Biodiesel, derived from vegetable oils or animal fats, generally has a higher energy density and better biodegradability, with lifecycle assessments highlighting its potential for reduced carbon emissions and improved energy balance when produced from waste or non-food feedstocks.

Future Prospects and Technological Innovations

Bioethanol and biodiesel exhibit promising future prospects driven by advancements in feedstock diversification, such as algae-based biofuels and genetically engineered crops with higher yield and resilience. Emerging technologies like enzymatic hydrolysis for bioethanol and catalytic transesterification for biodiesel enhance production efficiency and reduce environmental impact. Integration with smart grid systems and improvements in fuel blends are expected to accelerate adoption in transportation and energy sectors, supporting global decarbonization goals.

Transesterification

Transesterification is the key chemical process in biodiesel production, converting triglycerides into fatty acid methyl esters, whereas bioethanol is produced through fermentation of biomass without involving transesterification.

Fermentation

Bioethanol is produced through the fermentation of sugars by yeast, whereas biodiesel is synthesized via transesterification of fats and oils without fermentation.

Feedstock Variation

Bioethanol is primarily produced from sugarcane, corn, and other high-carbohydrate crops, while biodiesel is derived mainly from vegetable oils, animal fats, and recycled cooking oils, highlighting significant feedstock variation between the two biofuels.

Lipid Extraction

Biodiesel production relies heavily on efficient lipid extraction from oil-rich feedstocks like algae and oilseeds, whereas bioethanol is primarily derived from fermentable sugars in biomass without involving lipid extraction processes.

Lignocellulosic Biomass

Lignocellulosic biomass offers a sustainable feedstock for bioethanol production by fermenting cellulose and hemicellulose, whereas biodiesel primarily relies on lipid-based feedstocks like vegetable oils and animal fats.

Enzymatic Hydrolysis

Enzymatic hydrolysis enhances bioethanol production by efficiently converting cellulose into fermentable sugars, whereas biodiesel primarily involves transesterification of oils and fats without enzymatic hydrolysis.

Glycerol Byproduct

Bioethanol production generates minimal glycerol as a byproduct, whereas biodiesel manufacturing produces significant amounts of glycerol, which can be refined for pharmaceutical and industrial use.

Ethanol Yield

Bioethanol typically yields higher energy output per hectare compared to biodiesel, producing approximately 4,000 to 6,000 liters of ethanol per hectare from crops like corn or sugarcane.

Emulsification Stability

Bioethanol exhibits lower emulsification stability compared to biodiesel due to its higher polarity and water miscibility, making biodiesel more suitable for stable fuel blends in diesel engines.

Cetane Number

Biodiesel has a significantly higher cetane number, typically between 48 and 65, compared to bioethanol's low cetane number of around 8, making biodiesel more efficient for compression ignition engines.

Bioethanol vs Biodiesel Infographic

njnir.com

njnir.com