Bio-based polymers offer a sustainable alternative to petroleum-based polymers by utilizing renewable resources, reducing carbon footprint, and enhancing biodegradability. These polymers exhibit comparable mechanical and thermal properties, enabling their use in diverse applications such as packaging, automotive parts, and medical devices. Advances in chemical engineering have improved the scalability and cost-effectiveness of bio-based polymer production, promoting a shift toward environmentally friendly materials in the industry.

Table of Comparison

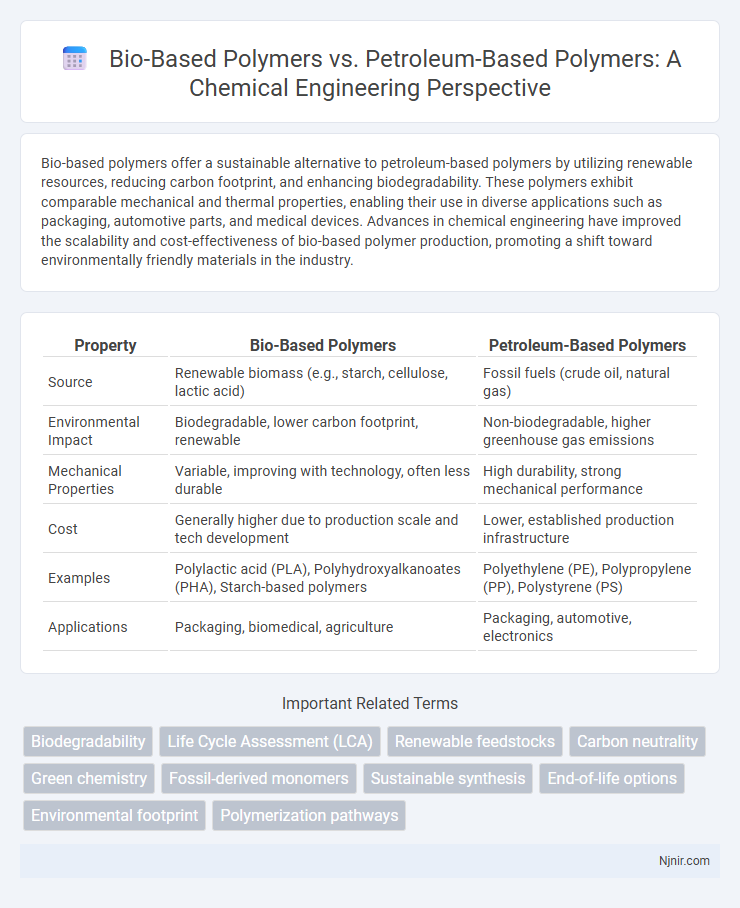

| Property | Bio-Based Polymers | Petroleum-Based Polymers |

|---|---|---|

| Source | Renewable biomass (e.g., starch, cellulose, lactic acid) | Fossil fuels (crude oil, natural gas) |

| Environmental Impact | Biodegradable, lower carbon footprint, renewable | Non-biodegradable, higher greenhouse gas emissions |

| Mechanical Properties | Variable, improving with technology, often less durable | High durability, strong mechanical performance |

| Cost | Generally higher due to production scale and tech development | Lower, established production infrastructure |

| Examples | Polylactic acid (PLA), Polyhydroxyalkanoates (PHA), Starch-based polymers | Polyethylene (PE), Polypropylene (PP), Polystyrene (PS) |

| Applications | Packaging, biomedical, agriculture | Packaging, automotive, electronics |

Introduction to Polymer Sources

Bio-based polymers are derived from renewable biological sources such as plant starch, cellulose, and vegetable oils, offering a sustainable alternative to traditional petroleum-based polymers produced from fossil fuels like crude oil and natural gas. These renewable sources enable reduced carbon emissions and decreased dependency on non-renewable resources. Advances in biopolymer synthesis and processing technologies are enhancing their mechanical properties and broadening applications in packaging, automotive, and biomedical industries.

Overview of Bio-Based Polymers

Bio-based polymers are derived from renewable biological resources such as plants, algae, and microorganisms, offering a sustainable alternative to traditional petroleum-based polymers made from fossil fuels. These polymers exhibit diverse properties suitable for packaging, agriculture, and biomedical applications while contributing to reduced carbon footprint and enhanced biodegradability. Advances in biotechnology and green chemistry have accelerated the development of bio-based polymers like polylactic acid (PLA) and polyhydroxyalkanoates (PHA), positioning them as key materials in the transition to a circular economy.

Characteristics of Petroleum-Based Polymers

Petroleum-based polymers are characterized by their high mechanical strength, durability, and resistance to heat and chemicals, making them widely used in packaging, automotive, and construction industries. These polymers, derived from non-renewable fossil fuels, typically exhibit excellent processability and cost-effectiveness, contributing to their dominance in global polymer markets. However, their non-biodegradable nature and environmental persistence pose significant ecological challenges compared to bio-based alternatives.

Environmental Impact Comparison

Bio-based polymers significantly reduce carbon footprint and reliance on fossil fuels compared to petroleum-based polymers, as they are derived from renewable resources like corn, sugarcane, and cellulose. Their biodegradability and lower greenhouse gas emissions during production and disposal contribute to reduced environmental pollution and enhanced sustainability. However, challenges such as land use, water consumption, and energy intensity in bio-based polymer production must be addressed to optimize overall environmental benefits.

Production Processes and Feedstocks

Bio-based polymers are produced using renewable feedstocks such as corn, sugarcane, and cellulose through fermentation, polymerization, or enzymatic processes, leading to lower carbon footprints and enhanced biodegradability. Petroleum-based polymers are synthesized from non-renewable fossil fuels like crude oil and natural gas via complex chemical reactions such as cracking and polymerization, resulting in materials with high durability but significant environmental impact. The production of bio-based polymers emphasizes sustainable resource utilization, while petroleum-based polymer manufacturing relies heavily on finite feedstocks and energy-intensive processes.

Mechanical and Thermal Properties

Bio-based polymers typically exhibit lower mechanical strength and thermal resistance compared to petroleum-based polymers, limiting their use in high-performance applications. Petroleum-based polymers such as polyethylene and polypropylene offer superior tensile strength, impact resistance, and higher melting points, making them more suitable for demanding industrial uses. Advances in bio-based polymer development aim to enhance properties like Young's modulus and thermal degradation temperature to close this performance gap.

Biodegradability and End-of-Life Options

Bio-based polymers generally exhibit superior biodegradability compared to petroleum-based polymers, breaking down more efficiently in natural environments due to their origin from renewable biomass. End-of-life options for bio-based polymers often include composting and anaerobic digestion, whereas petroleum-based polymers primarily rely on mechanical recycling or landfilling, posing greater environmental persistence. These differences significantly impact waste management strategies and environmental sustainability efforts in polymer applications.

Economic Considerations and Market Trends

Bio-based polymers demonstrate increasing market potential due to rising consumer demand for sustainable products and favorable government incentives supporting green technologies. Petroleum-based polymers maintain dominance due to established infrastructure, lower raw material costs, and economies of scale, though fluctuating oil prices introduce volatility in pricing. Economic considerations hinge on cost-competitiveness, with bio-based polymers gaining traction through advancements in production technology and expanding applications in packaging and automotive industries.

Technological Challenges and Opportunities

Bio-based polymers face technological challenges including limited mechanical strength, slower production rates, and higher costs compared to petroleum-based polymers. Advancements in bioconversion processes, catalyst development, and molecular engineering offer opportunities to enhance performance and scalability of bio-based polymers. Developing cost-effective, sustainable production methods can enable bio-based polymers to compete with traditional petroleum-based materials in diverse industrial applications.

Future Prospects in Polymer Engineering

Bio-based polymers present a sustainable alternative to petroleum-based polymers, offering renewable feedstocks that reduce carbon footprint and enhance biodegradability in polymer engineering. Advances in enzymatic synthesis, microbial fermentation, and genetic engineering are driving the development of high-performance bio-based polymers with tailored properties for diverse applications. Future prospects include integrating bio-based polymers into circular economy models, improving material recyclability, and scaling production to meet global demand while minimizing environmental impact.

Biodegradability

Bio-based polymers exhibit superior biodegradability compared to petroleum-based polymers, significantly reducing environmental persistence and promoting sustainable waste management.

Life Cycle Assessment (LCA)

Life Cycle Assessment (LCA) reveals bio-based polymers typically have lower carbon footprints and reduced fossil fuel dependency compared to petroleum-based polymers, although variations depend on feedstock, production methods, and end-of-life scenarios.

Renewable feedstocks

Bio-based polymers utilize renewable feedstocks derived from plants and biomass, reducing reliance on finite petroleum-based resources and enhancing sustainability in polymer production.

Carbon neutrality

Bio-based polymers contribute to carbon neutrality by capturing atmospheric CO2 during biomass growth, whereas petroleum-based polymers release fossil carbon, increasing overall carbon emissions.

Green chemistry

Bio-based polymers derived from renewable resources minimize environmental impact by reducing carbon footprint and promoting sustainability compared to petroleum-based polymers linked to fossil fuel depletion and pollution.

Fossil-derived monomers

Fossil-derived monomers in petroleum-based polymers contribute significantly to environmental pollution and reliance on non-renewable resources, whereas bio-based polymers utilize renewable biomass sources, reducing carbon footprint and enhancing sustainability.

Sustainable synthesis

Sustainable synthesis of bio-based polymers utilizes renewable resources and reduces carbon footprint compared to traditional petroleum-based polymers derived from finite fossil fuels.

End-of-life options

Bio-based polymers typically offer more sustainable end-of-life options such as biodegradability and compostability compared to petroleum-based polymers, which predominantly rely on recycling or landfilling.

Environmental footprint

Bio-based polymers significantly reduce environmental footprint by lowering greenhouse gas emissions and enhancing biodegradability compared to petroleum-based polymers.

Polymerization pathways

Bio-based polymers primarily utilize renewable monomers through enzymatic or fermentation polymerization pathways, while petroleum-based polymers rely on conventional chemical polymerization of hydrocarbon monomers derived from fossil fuels.

bio-based polymers vs petroleum-based polymers Infographic

njnir.com

njnir.com