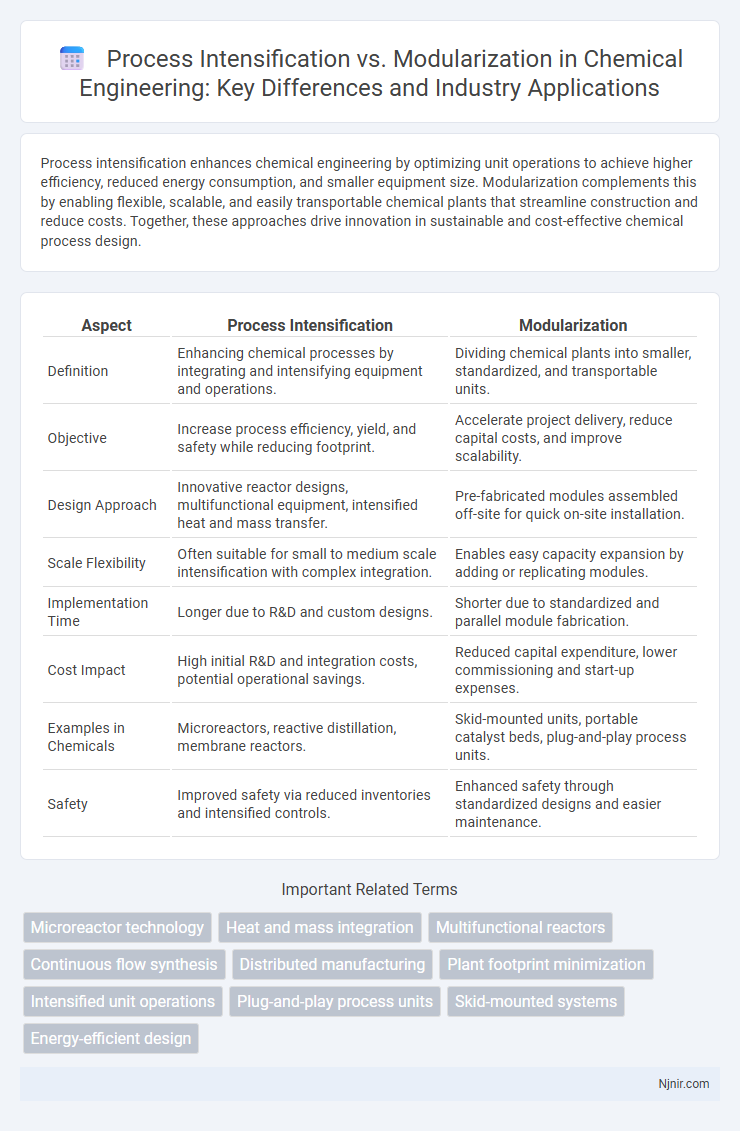

Process intensification enhances chemical engineering by optimizing unit operations to achieve higher efficiency, reduced energy consumption, and smaller equipment size. Modularization complements this by enabling flexible, scalable, and easily transportable chemical plants that streamline construction and reduce costs. Together, these approaches drive innovation in sustainable and cost-effective chemical process design.

Table of Comparison

| Aspect | Process Intensification | Modularization |

|---|---|---|

| Definition | Enhancing chemical processes by integrating and intensifying equipment and operations. | Dividing chemical plants into smaller, standardized, and transportable units. |

| Objective | Increase process efficiency, yield, and safety while reducing footprint. | Accelerate project delivery, reduce capital costs, and improve scalability. |

| Design Approach | Innovative reactor designs, multifunctional equipment, intensified heat and mass transfer. | Pre-fabricated modules assembled off-site for quick on-site installation. |

| Scale Flexibility | Often suitable for small to medium scale intensification with complex integration. | Enables easy capacity expansion by adding or replicating modules. |

| Implementation Time | Longer due to R&D and custom designs. | Shorter due to standardized and parallel module fabrication. |

| Cost Impact | High initial R&D and integration costs, potential operational savings. | Reduced capital expenditure, lower commissioning and start-up expenses. |

| Examples in Chemicals | Microreactors, reactive distillation, membrane reactors. | Skid-mounted units, portable catalyst beds, plug-and-play process units. |

| Safety | Improved safety via reduced inventories and intensified controls. | Enhanced safety through standardized designs and easier maintenance. |

Introduction to Process Intensification and Modularization

Process intensification involves redesigning chemical processes to achieve significant improvements in efficiency, safety, and sustainability by utilizing innovative equipment and techniques that enhance mass and heat transfer. Modularization focuses on constructing process units as compact, pre-fabricated modules that can be easily transported, assembled, and scaled, enabling faster deployment and improved quality control. Both strategies aim to optimize production by reducing footprint, capital cost, and energy consumption while enabling flexible and adaptive manufacturing solutions.

Core Principles: Comparing Process Intensification and Modularization

Process intensification centers on redesigning unit operations to enhance efficiency, reduce energy consumption, and minimize equipment size by integrating multiple processes into a single unit. Modularization emphasizes designing standardized, prefabricated units for rapid deployment, scalability, and ease of maintenance within larger systems. Both approaches aim to optimize production but differ where intensification focuses on process innovation while modularization prioritizes structural flexibility and repeatability.

Technological Drivers in Modern Chemical Engineering

Technological drivers in modern chemical engineering highlight process intensification as a key approach to enhance reaction rates, improve heat and mass transfer, and reduce equipment size through advanced catalysts, microreactors, and novel separation technologies. Modularization complements this by enabling flexible, scalable, and rapid deployment of standardized process units, leveraging digital automation and advanced control systems for optimized operation. Together, these innovations drive efficiency, sustainability, and economic competitiveness in chemical manufacturing.

Advantages of Process Intensification in Chemical Processes

Process intensification in chemical processes enhances efficiency by integrating multiple unit operations into a single, compact system, significantly reducing energy consumption and equipment footprint. This approach improves reaction rates and selectivity, leading to higher yields and reduced waste generation. The intensified processes enable better heat and mass transfer, resulting in safer and more sustainable chemical manufacturing.

Benefits and Challenges of Modularization

Modularization enhances construction efficiency, reduces project time, and improves quality control by using pre-fabricated, standardized units in process industries. Challenges include logistical complexities, higher initial design coordination, and limited flexibility for future process modifications. This approach supports rapid deployment and scalability but requires careful planning to balance standardization with customization needs.

Impact on Capital and Operational Expenditure

Process intensification significantly reduces capital expenditure by minimizing equipment size and increasing throughput, leading to lower installation and material costs. Operational expenditure decreases through enhanced energy efficiency and reduced utility consumption, while improved reaction control minimizes waste and downtime. Modularization cuts capital costs by enabling factory-built, scalable units that shorten construction timelines and reduce site labor expenses, and operational costs benefit from standardized maintenance procedures and easier upgrades.

Flexibility and Scalability in Chemical Plant Design

Process intensification enhances flexibility in chemical plant design by integrating multiple unit operations into compact, efficient systems, enabling rapid adaptation to varying production scales and feedstock changes. Modularization supports scalability through standardized, prefabricated units that can be easily added or reconfigured, reducing construction time and costs while allowing phased capacity expansion. Combining both approaches optimizes operational flexibility and scalability, facilitating quicker deployment and adjustment of processes in response to market demands.

Safety and Environmental Considerations

Process intensification enhances safety by reducing equipment size and inventory, minimizing the risk of hazardous material release, while modularization improves environmental management through standardized, pre-fabricated units that limit on-site emissions and waste. Intensified processes often enable better containment and control of reactions, leading to lower accident probabilities and reduced environmental footprint. Modular designs facilitate easier upgrades and maintenance, ensuring compliance with evolving safety and environmental regulations.

Case Studies: Real-World Applications

Case studies in process intensification reveal significant improvements in energy efficiency and reaction rates, such as in the chemical and pharmaceutical industries where intensified reactors reduce footprint and emissions. Modularization demonstrates value in offshore oil platforms and water treatment plants by enabling scalable, transportable units that accelerate project timelines and reduce costs. Real-world applications emphasize that combining both approaches can optimize operational performance while maintaining flexibility and scalability.

Future Trends and Integration Opportunities

Process intensification leverages advanced technologies such as microreactors and novel heat exchangers to enhance efficiency, reduce energy consumption, and minimize equipment size, driving future trends toward more sustainable and flexible production. Modularization complements this by enabling scalable, plug-and-play units that facilitate rapid deployment, easier maintenance, and enhanced integration with digital control systems and Industry 4.0 frameworks. Integration opportunities lie in combining intensified processes within modular platforms to create highly adaptable manufacturing systems that optimize resource utilization and support decentralized production networks.

Microreactor technology

Microreactor technology enhances process intensification by enabling precise temperature control, improved mass transfer, and safer scale-up compared to traditional modularization methods.

Heat and mass integration

Process intensification enhances heat and mass integration by combining functions within a single unit to improve efficiency, while modularization optimizes these integrations by standardizing and scaling discrete units for flexible, decentralized deployment.

Multifunctional reactors

Multifunctional reactors in process intensification integrate reaction and separation steps within a single unit, significantly enhancing efficiency and reducing footprint compared to modularization, which emphasizes discrete, scalable process units.

Continuous flow synthesis

Continuous flow synthesis in process intensification enhances reaction efficiency and scalability by integrating modularization principles for flexible, compact, and automated chemical production units.

Distributed manufacturing

Distributed manufacturing enhances process intensification by enabling localized, modular production units that reduce transportation costs, increase flexibility, and improve resource efficiency.

Plant footprint minimization

Process intensification significantly reduces plant footprint by integrating multiple unit operations into compact systems, while modularization minimizes footprint through prefabricated, scalable modules that streamline construction and installation.

Intensified unit operations

Intensified unit operations enhance process efficiency by combining multiple functions into compact designs, significantly reducing energy consumption and footprint compared to traditional modularization strategies.

Plug-and-play process units

Plug-and-play process units in process intensification enable scalable, seamless integration and rapid deployment compared to the fixed, factory-built approach of modularization, enhancing operational flexibility and efficiency.

Skid-mounted systems

Skid-mounted systems in process intensification offer compact, integrated unit operations that enhance scalability and reduce installation time compared to traditional modularization approaches.

Energy-efficient design

Process intensification significantly enhances energy-efficient design by integrating multiple unit operations into single compact systems, whereas modularization improves energy efficiency primarily through standardized, scalable, and easily maintainable units.

Process intensification vs Modularization Infographic

njnir.com

njnir.com