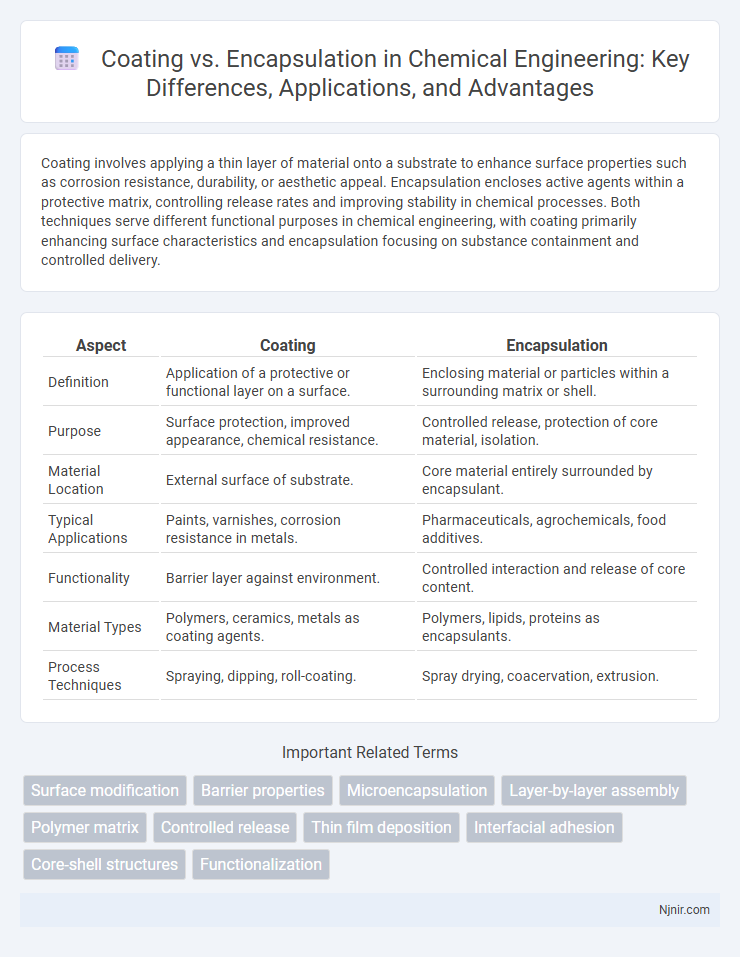

Coating involves applying a thin layer of material onto a substrate to enhance surface properties such as corrosion resistance, durability, or aesthetic appeal. Encapsulation encloses active agents within a protective matrix, controlling release rates and improving stability in chemical processes. Both techniques serve different functional purposes in chemical engineering, with coating primarily enhancing surface characteristics and encapsulation focusing on substance containment and controlled delivery.

Table of Comparison

| Aspect | Coating | Encapsulation |

|---|---|---|

| Definition | Application of a protective or functional layer on a surface. | Enclosing material or particles within a surrounding matrix or shell. |

| Purpose | Surface protection, improved appearance, chemical resistance. | Controlled release, protection of core material, isolation. |

| Material Location | External surface of substrate. | Core material entirely surrounded by encapsulant. |

| Typical Applications | Paints, varnishes, corrosion resistance in metals. | Pharmaceuticals, agrochemicals, food additives. |

| Functionality | Barrier layer against environment. | Controlled interaction and release of core content. |

| Material Types | Polymers, ceramics, metals as coating agents. | Polymers, lipids, proteins as encapsulants. |

| Process Techniques | Spraying, dipping, roll-coating. | Spray drying, coacervation, extrusion. |

Introduction to Coating and Encapsulation in Chemical Engineering

Coating in chemical engineering involves applying a thin layer of material to a substrate to protect it from corrosion, wear, or chemical exposure, enhancing durability and performance. Encapsulation refers to the process of enveloping active substances within a carrier material to control release rates, improve stability, and prevent degradation. Both techniques are crucial for optimizing material properties and extending the functional lifespan of industrial products.

Fundamental Principles of Coating Technologies

Coating technologies involve the application of a continuous layer of material onto a substrate to provide protection, enhance surface properties, or impart functional characteristics such as corrosion resistance, wear resistance, or aesthetic appeal. Fundamental principles include surface preparation, coating composition, and deposition methods, which determine adhesion, durability, and performance of the coating. Techniques such as thermal spraying, chemical vapor deposition, and electroplating are commonly employed to achieve uniform, controlled coatings tailored to specific industrial applications.

Core Concepts of Encapsulation Techniques

Encapsulation techniques involve enclosing active ingredients within a protective barrier to improve stability, control release, and enhance bioavailability, commonly using materials such as polymers, lipids, or proteins. Core methods include physical encapsulation via spray drying or coacervation, chemical encapsulation through polymerization, and molecular inclusion using cyclodextrins. Effective encapsulation optimizes ingredient protection against environmental factors, targeted delivery, and sustained release profiles, critical in pharmaceuticals, food technology, and cosmetics.

Material Selection Criteria for Coating and Encapsulation

Material selection criteria for coating emphasize adhesion strength, chemical resistance, and thermal stability to protect substrates from environmental and mechanical damage. Encapsulation materials must offer excellent electrical insulation, moisture barrier properties, and flexibility to safeguard sensitive components in electronics and pharmaceuticals. Both processes require compatibility with the underlying substrate and durability under operational conditions for optimal performance.

Comparative Analysis: Coating vs Encapsulation

Coating provides a surface layer that protects materials from environmental factors, while encapsulation fully encloses the core substance, offering superior protection and controlled release properties. Coatings typically enhance durability and resistance to wear, moisture, and corrosion, whereas encapsulation is crucial for applications requiring isolation from external interactions, such as pharmaceuticals and electronics. Both techniques differ in application methods and performance outcomes, with coatings favored for surface enhancement and encapsulation preferred for safeguarding sensitive or reactive components.

Process Technologies and Equipment Used

Coating and encapsulation utilize distinct process technologies tailored to their applications, with coating often relying on methods such as spray coating, dip coating, and roll-to-roll coating employing equipment like spray guns, coating knives, and rollers to apply uniform thin layers on surfaces. Encapsulation involves technologies like microencapsulation, nanoencapsulation, and fluidized bed coating, using specialized equipment such as encapsulation machines, fluidized bed coaters, and spray dryers to encase materials within protective shells. Both processes require precise control over parameters like thickness, curing time, and temperature, achieved through automated systems and real-time monitoring tools integrated into the coating and encapsulation equipment.

Performance and Functional Properties

Coating enhances surface durability, corrosion resistance, and aesthetic appeal by applying a protective layer that isolates the substrate from environmental factors. Encapsulation improves performance by fully enclosing components, providing superior protection against moisture, dust, and mechanical stress, which extends the lifespan and reliability of electronic devices. Both methods impact thermal management and electrical insulation differently, with coating offering surface-level protection and encapsulation delivering comprehensive safeguarding of sensitive parts.

Applications in the Chemical Engineering Sector

Coating and encapsulation are critical techniques in chemical engineering for enhancing material properties and process efficiency. Coating applications include corrosion resistance, wear protection, and chemical barrier formation on equipment and pipelines using materials like polymers, ceramics, and metallic layers. Encapsulation is widely used for controlled release of catalysts, additives, and hazardous substances, improving reaction control, safety, and environmental compliance in chemical manufacturing processes.

Challenges and Limitations of Each Method

Coating faces challenges such as poor adhesion on certain substrates, leading to delamination and reduced durability, while environmental factors like UV exposure and moisture can degrade coated surfaces over time. Encapsulation limitations include complexity in achieving uniform coverage, risk of trapping impurities, and increased production costs due to additional material and processing requirements. Both methods require careful material selection and process control to optimize performance and longevity in various applications.

Future Trends and Innovations in Coating and Encapsulation

Future trends in coating and encapsulation emphasize advanced nanomaterials and smart coatings that enhance durability, self-healing properties, and targeted delivery systems. Innovations include bio-based and environmentally friendly coatings that reduce ecological impact while improving performance in sectors like electronics, pharmaceuticals, and construction. Emerging technologies such as stimuli-responsive encapsulation enable precise control over release mechanisms, fostering growth in drug delivery and agricultural applications.

Surface modification

Coating enhances surface properties by applying a protective layer, while encapsulation involves surrounding particles or materials completely, providing improved surface modification for controlled release and protection.

Barrier properties

Encapsulation provides superior barrier properties by fully enclosing materials to prevent moisture, oxygen, and contaminants penetration, whereas coatings primarily offer surface protection with less comprehensive barrier effectiveness.

Microencapsulation

Microencapsulation enhances product stability and controlled release by encapsulating active ingredients within protective coatings that prevent degradation and improve functionality.

Layer-by-layer assembly

Layer-by-layer assembly enhances coating precision by alternately depositing oppositely charged materials, enabling controlled encapsulation for improved material protection and functionality.

Polymer matrix

Polymer matrix encapsulation provides superior protection and mechanical stability compared to coating by fully embedding active materials within the polymer, enhancing durability and performance in harsh environments.

Controlled release

Coating provides a physical barrier on the surface of a material to regulate controlled release rates, while encapsulation encloses the active agent within a matrix or shell, enabling more precise and sustained controlled release profiles.

Thin film deposition

Thin film deposition techniques such as chemical vapor deposition (CVD) and atomic layer deposition (ALD) are essential for coating surfaces with uniform layers, while encapsulation involves creating protective barriers around materials to enhance durability and prevent contamination.

Interfacial adhesion

Encapsulation provides superior interfacial adhesion by fully surrounding and isolating the substrate, whereas coating offers only surface coverage that may result in weaker adhesion and increased susceptibility to delamination.

Core-shell structures

Core-shell structures enhance material performance by using coatings to provide surface protection while encapsulation encloses the core completely, optimizing functionality and stability in applications like drug delivery and catalysis.

Functionalization

Coating enhances surface functionalization by providing a protective layer that modifies surface properties, while encapsulation embeds functional agents within a matrix to enable controlled release and improved stability.

Coating vs Encapsulation Infographic

njnir.com

njnir.com