Microreactors offer enhanced heat and mass transfer capabilities compared to macroreactors, resulting in improved reaction control and higher safety levels. Their small channel dimensions enable precise temperature regulation and faster mixing, which boosts reaction efficiency and selectivity. In contrast, macroreactors are suitable for large-scale production but often face challenges with uniformity and scalability in complex reactions.

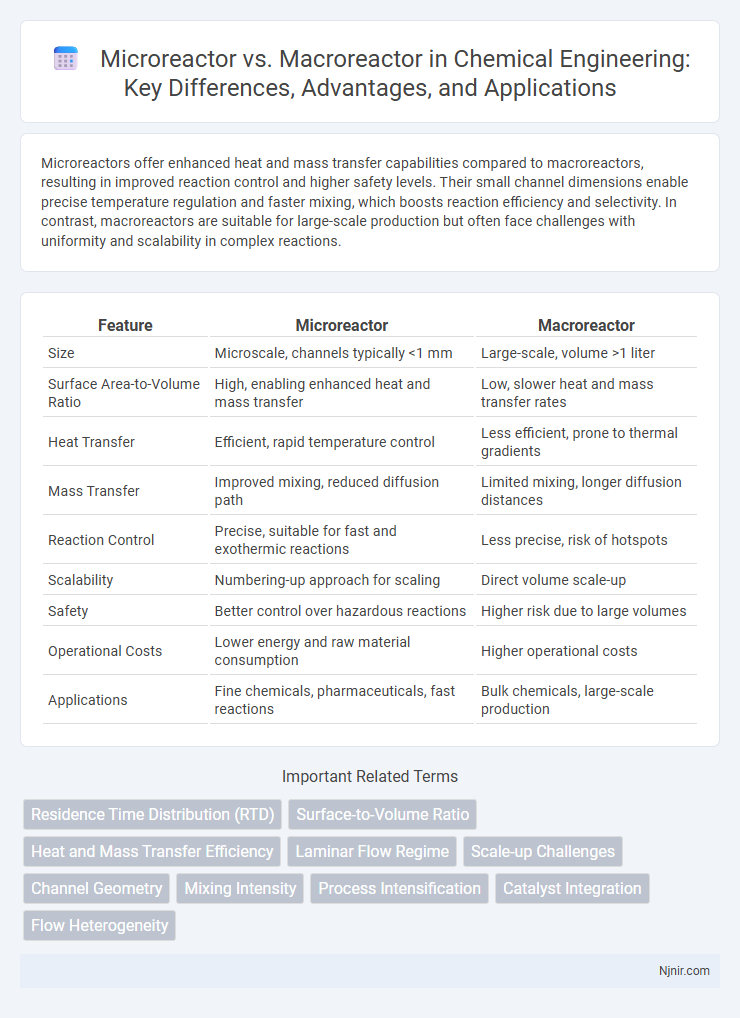

Table of Comparison

| Feature | Microreactor | Macroreactor |

|---|---|---|

| Size | Microscale, channels typically <1 mm | Large-scale, volume >1 liter |

| Surface Area-to-Volume Ratio | High, enabling enhanced heat and mass transfer | Low, slower heat and mass transfer rates |

| Heat Transfer | Efficient, rapid temperature control | Less efficient, prone to thermal gradients |

| Mass Transfer | Improved mixing, reduced diffusion path | Limited mixing, longer diffusion distances |

| Reaction Control | Precise, suitable for fast and exothermic reactions | Less precise, risk of hotspots |

| Scalability | Numbering-up approach for scaling | Direct volume scale-up |

| Safety | Better control over hazardous reactions | Higher risk due to large volumes |

| Operational Costs | Lower energy and raw material consumption | Higher operational costs |

| Applications | Fine chemicals, pharmaceuticals, fast reactions | Bulk chemicals, large-scale production |

Introduction to Microreactors and Macroreactors

Microreactors are compact devices with channels typically less than 1 millimeter wide, enabling enhanced heat and mass transfer rates, precise control over chemical reactions, and increased safety. Macroreactors are larger-scale reactors used for bulk chemical production with volume capacities ranging from liters to cubic meters, offering scalability but often limited by slower heat dissipation and less uniform mixing. The distinct differences in size, operational efficiency, and control mechanisms make microreactors suitable for high-throughput screening and specialized synthesis, while macroreactors remain essential for industrial-scale manufacturing.

Fundamental Design Differences

Microreactors feature channels with diameters typically less than 1 millimeter, enabling enhanced heat and mass transfer due to high surface-to-volume ratios, which contrasts with macroreactors that have larger vessels ranging from liters to cubic meters. The fundamental design of microreactors involves continuous flow operation and precise control over reaction parameters, whereas macroreactors often utilize batch or semi-batch processing with less uniform temperature and concentration profiles. Material choices for microreactors often include silicon or glass for microfabrication precision, while macroreactors generally employ stainless steel or glass-lined steel to withstand industrial-scale pressures and temperatures.

Material Selection and Construction

Microreactors utilize materials such as stainless steel, glass, and silicon due to their ability to withstand high pressures and enable precise heat transfer, while ensuring chemical compatibility for small-scale reactions. Macroreactors often employ carbon steel or high-grade alloys to handle larger volumes and harsher reaction conditions with robust structural integrity. The compact design of microreactors allows for advanced microfabrication techniques, whereas macroreactors rely on traditional welding and casting methods for construction.

Heat and Mass Transfer Efficiency

Microreactors outperform macroreactors in heat and mass transfer efficiency due to their significantly higher surface-area-to-volume ratio, enabling rapid heat dissipation and uniform temperature control. Enhanced microscale flow dynamics in microreactors facilitate improved mixing and reduced concentration gradients, leading to faster reaction rates and higher selectivity. In contrast, macroreactors face limitations from slower heat transfer and less efficient mass transport, often resulting in temperature hotspots and lower process intensification.

Process Scalability and Throughput

Microreactors offer enhanced process scalability through parallelization, enabling precise control over reaction conditions and rapid heat transfer, which significantly improves product consistency and reduces scale-up risks. Macroreactors provide higher throughput per unit but often face challenges in maintaining uniform temperature and mixing, leading to variability in product quality during scale-up. Optimizing microreactor arrays can achieve comparable or superior throughput to macroreactors while maintaining superior control over reaction kinetics and safety profiles.

Safety and Hazard Management

Microreactors significantly enhance safety and hazard management by minimizing the volume of reactants and products at any given time, reducing the risk of large-scale explosions or toxic releases compared to macroreactors. Their compact design allows for better heat and mass transfer control, preventing hot spots and runaway reactions that often challenge traditional large-scale reactors. Continuous flow operation in microreactors also enables rapid quenching and safer handling of hazardous intermediates, improving overall process safety.

Reaction Control and Selectivity

Microreactors offer superior reaction control and enhanced selectivity compared to macroreactors due to their high surface-to-volume ratio, enabling precise temperature and mixing regulation. The improved heat and mass transfer in microreactors minimizes side reactions, resulting in higher product purity and yield. In contrast, macroreactors often face challenges with temperature gradients and slower mixing, leading to lower selectivity and less efficient reaction control.

Energy Consumption and Sustainability

Microreactors significantly reduce energy consumption by enabling precise temperature control and rapid heat transfer, which minimizes waste and enhances reaction efficiency compared to macroreactors. Their compact design supports sustainable practices by lowering raw material usage and enabling modular, on-demand chemical production, thus reducing the carbon footprint. In contrast, macroreactors often involve higher energy inputs and less efficient heat management, leading to increased operational costs and environmental impact.

Industrial Applications and Case Studies

Microreactors offer enhanced heat and mass transfer rates, enabling precise control over reaction conditions in pharmaceutical synthesis and fine chemical production, resulting in higher yields and reduced waste. Macroreactors remain essential for large-scale petrochemical processing and bulk chemical manufacturing due to their capacity for high throughput and established industrial infrastructure. Case studies from companies like BASF highlight microreactors' efficiency in continuous flow reactions, while Dow Chemical demonstrates macroreactors' reliability in large-volume polymer production.

Future Trends and Innovations

Microreactors are poised to revolutionize chemical manufacturing with advancements in modular design and increased process intensification, enabling safer, more efficient, and scalable production. Innovations in 3D printing and microfluidic control systems are enhancing microreactor customization, fostering rapid experimentation and real-time monitoring. Macroreactors continue evolving through integration with digital twin technologies and enhanced catalyst formulations, improving yields and energy efficiency for large-scale industrial applications.

Residence Time Distribution (RTD)

Microreactors exhibit narrower Residence Time Distribution (RTD) due to enhanced flow uniformity and reduced axial dispersion compared to macroreactors, resulting in improved reaction control and selectivity.

Surface-to-Volume Ratio

Microreactors exhibit significantly higher surface-to-volume ratios than macroreactors, enhancing heat transfer efficiency and reaction control in chemical processes.

Heat and Mass Transfer Efficiency

Microreactors achieve superior heat and mass transfer efficiency compared to macroreactors due to their high surface-to-volume ratio and enhanced fluid dynamics.

Laminar Flow Regime

Microreactors maintain precise control over chemical reactions through sustained laminar flow regimes, unlike macroreactors where turbulent flow often reduces reaction efficiency and selectivity.

Scale-up Challenges

Microreactors face significant scale-up challenges due to difficulties in maintaining efficient heat transfer and fluid dynamics uniformity compared to macroreactors.

Channel Geometry

Microreactors feature narrow, precisely engineered channel geometries that enhance heat and mass transfer rates compared to the larger, less uniform channel structures found in macroreactors.

Mixing Intensity

Microreactors provide significantly higher mixing intensity than macroreactors due to their enhanced surface-to-volume ratio and shorter diffusion paths, enabling faster and more efficient chemical reactions.

Process Intensification

Microreactors enable superior process intensification compared to macroreactors by offering enhanced heat and mass transfer, precise reaction control, and reduced energy consumption, resulting in higher reaction efficiency and safety.

Catalyst Integration

Microreactors enhance catalyst integration through higher surface-to-volume ratios and precise control over reaction environments compared to macroreactors.

Flow Heterogeneity

Microreactors exhibit significantly lower flow heterogeneity compared to macroreactors due to their enhanced laminar flow and precise control over fluid dynamics at microscale dimensions.

microreactor vs macroreactor Infographic

njnir.com

njnir.com