Microreactors offer enhanced heat and mass transfer rates compared to traditional reactors, enabling precise control over reaction conditions and improved safety for highly exothermic processes. Their compact size allows for rapid scalability and reduces reagent consumption, making them ideal for continuous flow synthesis and fine chemical production. Traditional reactors often require larger volumes and longer residence times, which can limit efficiency and increase energy consumption in large-scale chemical manufacturing.

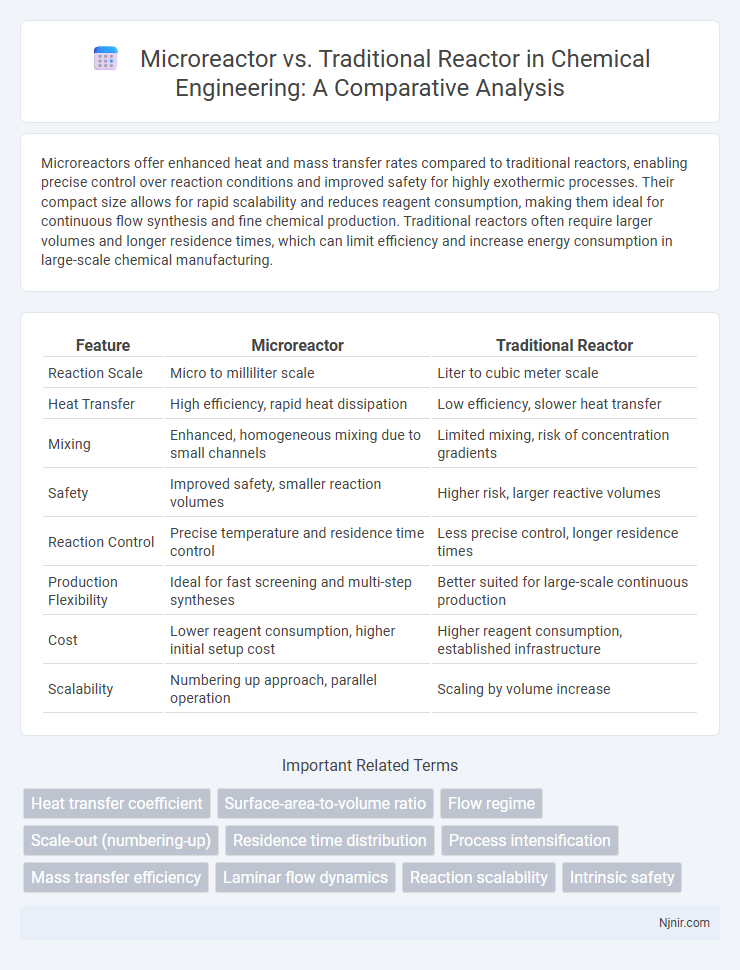

Table of Comparison

| Feature | Microreactor | Traditional Reactor |

|---|---|---|

| Reaction Scale | Micro to milliliter scale | Liter to cubic meter scale |

| Heat Transfer | High efficiency, rapid heat dissipation | Low efficiency, slower heat transfer |

| Mixing | Enhanced, homogeneous mixing due to small channels | Limited mixing, risk of concentration gradients |

| Safety | Improved safety, smaller reaction volumes | Higher risk, larger reactive volumes |

| Reaction Control | Precise temperature and residence time control | Less precise control, longer residence times |

| Production Flexibility | Ideal for fast screening and multi-step syntheses | Better suited for large-scale continuous production |

| Cost | Lower reagent consumption, higher initial setup cost | Higher reagent consumption, established infrastructure |

| Scalability | Numbering up approach, parallel operation | Scaling by volume increase |

Introduction to Chemical Reactors

Microreactors offer enhanced heat and mass transfer rates compared to traditional reactors due to their small channel dimensions, enabling precise temperature control and faster reaction kinetics. Traditional reactors, typically larger in scale, rely on bulk mixing and heating methods that can limit efficiency and selectivity in chemical processes. The compact design of microreactors facilitates continuous processing with improved safety and scalability for advanced chemical manufacturing applications.

Fundamentals of Microreactor Technology

Microreactor technology leverages microscale channels to enhance mass and heat transfer rates, significantly improving reaction efficiency compared to traditional reactors that operate at larger scales with lower surface-area-to-volume ratios. The fundamental advantage lies in precise control over reaction parameters, enabling rapid mixing, temperature uniformity, and safer handling of hazardous substances. Microreactors facilitate intensification of chemical processes, leading to higher yields, reduced waste, and scalability through parallelization.

Overview of Traditional Reactor Designs

Traditional reactor designs, such as batch, continuous stirred-tank reactors (CSTR), and plug flow reactors (PFR), rely on large-scale vessels for chemical reactions, promoting macroscale mixing and heat transfer. These reactors often face limitations in precise temperature control and reaction time, impacting yield and selectivity. Their scale and design produce higher energy requirements and lower surface area-to-volume ratios compared to microreactors, affecting reaction efficiency and safety management.

Scale and Throughput: Microreactors vs. Traditional Reactors

Microreactors offer significantly higher surface-area-to-volume ratios compared to traditional reactors, enabling enhanced heat and mass transfer at microscale dimensions. This scale advantage leads to faster reaction times and improved selectivity, while traditional reactors typically handle larger volumes but with reduced throughput efficiency. Microreactors excel in continuous flow processing, achieving greater throughput per unit volume despite their smaller size, making them ideal for fine chemical and pharmaceutical production.

Heat and Mass Transfer Efficiency

Microreactors exhibit superior heat and mass transfer efficiency compared to traditional reactors due to their high surface-area-to-volume ratio, enabling rapid heat dissipation and uniform temperature control. Enhanced mixing and reduced diffusion distances in microreactors lead to faster reaction rates and improved product selectivity. Traditional reactors often suffer from inefficient heat removal and mass transfer limitations, causing hotspots and uneven reaction conditions.

Process Safety and Control Comparisons

Microreactors offer enhanced process safety through improved thermal management and reduced inventory, minimizing the risk of runaway reactions compared to traditional reactors. Their compact design facilitates precise control over reaction parameters, allowing for rapid adjustments and better containment of hazardous materials. Traditional reactors often face challenges in maintaining uniform conditions and managing large-scale exothermic processes, which can lead to safety hazards and less responsive control systems.

Energy Consumption and Sustainability

Microreactors consume significantly less energy compared to traditional reactors due to their compact design and enhanced heat transfer efficiency, which reduces energy waste during chemical reactions. Their sustainable advantages include lower raw material usage and minimized emissions, supporting greener industrial processes. This energy-efficient operation contributes to reduced carbon footprints, making microreactors a favorable choice for sustainable chemical manufacturing.

Applications in Fine Chemicals and Pharmaceuticals

Microreactors offer precise control over reaction conditions, enabling enhanced selectivity and yield in fine chemicals and pharmaceutical synthesis compared to traditional reactors. Their high surface-to-volume ratio and rapid heat transfer facilitate efficient scale-up of complex multi-step reactions, critical for producing high-purity active pharmaceutical ingredients (APIs). Traditional reactors, while suited for large-scale batch processing, often face limitations in reaction time, safety, and scalability for highly sensitive or hazardous compounds commonly encountered in pharmaceutical manufacturing.

Challenges and Limitations of Microreactors

Microreactors face significant challenges such as limited scalability, which restricts their use in large-scale industrial processes compared to traditional reactors. The complexity of integrating microreactor systems with existing infrastructure and the high initial cost of microfabrication further limit widespread adoption. Issues with clogging, heat management, and pressure drops also present operational limitations unique to microreactors.

Future Trends in Reactor Technology

Microreactors offer enhanced heat and mass transfer rates, enabling safer and more efficient chemical processes compared to traditional reactors. Future trends highlight integration with advanced automation, AI-driven process control, and modular designs for scalability and rapid deployment. These innovations support sustainable manufacturing and real-time optimization in chemical industries.

Heat transfer coefficient

Microreactors exhibit heat transfer coefficients up to 100 times higher than traditional reactors due to their enhanced surface-to-volume ratio and efficient microchannel design.

Surface-area-to-volume ratio

Microreactors offer a significantly higher surface-area-to-volume ratio than traditional reactors, enhancing heat and mass transfer efficiency for improved reaction control and faster processing times.

Flow regime

Microreactors feature laminar flow regimes enabling precise control and enhanced mass transfer, whereas traditional reactors often operate under turbulent flow promoting bulk mixing but less precise reaction control.

Scale-out (numbering-up)

Microreactors enable efficient scale-out through numbering-up by integrating multiple small reactors, offering improved heat transfer, enhanced safety, and consistent product quality compared to traditional reactors that scale-up as a single large unit.

Residence time distribution

Microreactors exhibit narrower residence time distributions than traditional reactors, leading to improved reaction control and higher product selectivity.

Process intensification

Microreactors enable process intensification by providing enhanced mass and heat transfer rates, superior control over reaction conditions, and increased safety compared to traditional reactors.

Mass transfer efficiency

Microreactors achieve significantly higher mass transfer efficiency than traditional reactors due to their enhanced surface-area-to-volume ratio and superior mixing capabilities.

Laminar flow dynamics

Microreactors leverage precise laminar flow dynamics with high surface-to-volume ratios, enabling superior mass and heat transfer compared to the turbulent flow conditions typical in traditional reactors.

Reaction scalability

Microreactors enable precise reaction scalability through enhanced heat and mass transfer rates compared to traditional reactors, allowing efficient scale-up from lab to industrial production.

Intrinsic safety

Microreactors offer enhanced intrinsic safety through improved heat transfer and reduced reactant volumes compared to traditional reactors, minimizing risks of thermal runaway and hazardous leaks.

Microreactor vs Traditional reactor Infographic

njnir.com

njnir.com