Process intensification in chemical engineering optimizes system performance by integrating equipment and enhancing mass, heat, and momentum transfer rates beyond conventional design limits. This approach reduces equipment size, energy consumption, and environmental impact while improving safety and product quality. Conventional design typically relies on large, discrete units with limited operational flexibility and higher capital and operational costs.

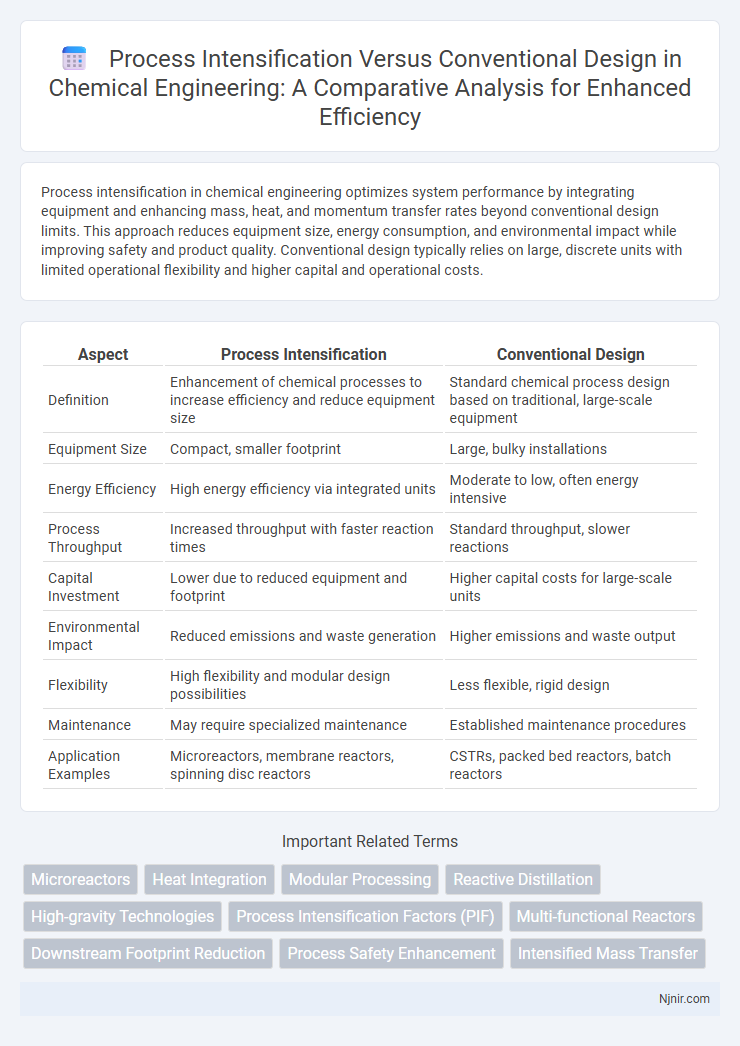

Table of Comparison

| Aspect | Process Intensification | Conventional Design |

|---|---|---|

| Definition | Enhancement of chemical processes to increase efficiency and reduce equipment size | Standard chemical process design based on traditional, large-scale equipment |

| Equipment Size | Compact, smaller footprint | Large, bulky installations |

| Energy Efficiency | High energy efficiency via integrated units | Moderate to low, often energy intensive |

| Process Throughput | Increased throughput with faster reaction times | Standard throughput, slower reactions |

| Capital Investment | Lower due to reduced equipment and footprint | Higher capital costs for large-scale units |

| Environmental Impact | Reduced emissions and waste generation | Higher emissions and waste output |

| Flexibility | High flexibility and modular design possibilities | Less flexible, rigid design |

| Maintenance | May require specialized maintenance | Established maintenance procedures |

| Application Examples | Microreactors, membrane reactors, spinning disc reactors | CSTRs, packed bed reactors, batch reactors |

Defining Process Intensification in Chemical Engineering

Process Intensification in chemical engineering refers to innovative design strategies that significantly enhance process efficiency, reduce equipment size, and minimize energy consumption compared to conventional design methods. It involves integrating multiple unit operations into a single system, using advanced materials, and employing novel technologies to optimize reaction rates and mass transfer. This approach aims to achieve higher productivity and sustainability within chemical plants by overcoming limitations of traditional, large-scale processes.

Conventional Process Design: Principles and Practices

Conventional process design relies on established engineering principles such as steady-state operation, linear scalability, and equipment standardization to ensure safety, reliability, and ease of control in chemical production. It typically involves distinct unit operations arranged sequentially, allowing for straightforward troubleshooting and maintenance but often resulting in larger equipment and higher energy consumption. Conventional practices emphasize detailed process simulations, conservative design margins, and adherence to industry codes to minimize operational risks and optimize performance within well-understood boundaries.

Key Drivers for Process Intensification Adoption

Process intensification adoption is driven by the need to enhance energy efficiency, reduce equipment size, and minimize environmental impact compared to conventional design. Key factors include higher throughput, improved heat and mass transfer rates, and the ability to integrate multiple unit operations into a single compact system. Economic incentives such as lower capital and operating costs alongside regulatory pressures for sustainability further accelerate the shift toward intensified processes.

Comparing Equipment Size and Footprint

Process intensification significantly reduces equipment size and footprint compared to conventional design by integrating multiple unit operations into a single compact system. Smaller equipment leads to lower capital costs, reduced energy consumption, and easier scalability in industrial processes. Conventional designs typically require larger, standalone units that occupy more space and involve higher maintenance and operational complexities.

Energy Efficiency: Intensified vs. Conventional Processes

Process intensification significantly enhances energy efficiency by integrating multiple operations into compact units, reducing energy consumption per unit of output compared to conventional designs. Intensified processes utilize innovative technologies such as microreactors and heat integration, which minimize energy losses and improve thermal management. Conventional processes often involve larger equipment and sequential steps, leading to higher energy demands and inefficiencies.

Safety Considerations in Intensified and Conventional Systems

Process intensification enhances safety by reducing equipment volume and hazardous inventory, minimizing exposure to dangerous chemicals and lowering the risk of accidents compared to conventional design. Conventional systems often involve larger reactors and storage vessels, increasing potential hazards such as leaks, spills, and explosions due to greater quantities of reactive substances. Intensified designs integrate advanced control and containment strategies, improving operational safety through better thermal management and rapid response to process deviations.

Economic Analysis: Capital and Operational Costs

Process intensification significantly reduces capital costs by minimizing equipment size and footprint, leading to lower investment in materials and construction. Operational costs decrease due to enhanced energy efficiency, reduced raw material consumption, and improved process integration, resulting in lower utility expenses and maintenance requirements. Conventional designs often incur higher capital expenditures and operational costs due to larger equipment and less efficient energy utilization.

Case Studies: Successful Process Intensification Implementations

Case studies demonstrate that process intensification (PI) significantly enhances efficiency by reducing equipment size, energy consumption, and production costs compared to conventional design. For example, integrating reactive distillation in chemical synthesis led to a 30% increase in yield and 25% energy savings in pharmaceutical manufacturing. Industrial applications of membrane reactors in hydrogen production also highlight increased conversion rates and lower environmental impact versus traditional reactors.

Scalability and Flexibility Challenges

Process intensification offers significant advantages in scalability by enabling compact equipment designs that enhance mass and heat transfer rates, facilitating easier scale-up compared to conventional designs typically limited by larger equipment footprints. Flexibility challenges are reduced as intensified processes often integrate multifunctional units, allowing rapid adaptation to varying production demands and feedstock variations, which conventional systems struggle to accommodate due to rigid, unit-specific configurations. These attributes result in intensified processes providing superior operational agility and cost-effective scalability over traditional chemical engineering methods.

Future Trends and Opportunities in Process Design

Process intensification offers transformative potential in process design by enhancing efficiency, reducing equipment size, and minimizing energy consumption compared to conventional design methods. Emerging trends emphasize integration of advanced materials, modular units, and digital twins to optimize performance and accelerate scalability. Opportunities arise from combining process intensification with Industry 4.0 technologies, enabling smart, adaptive systems that respond to dynamic operational demands and sustainability goals.

Microreactors

Microreactors enable process intensification by offering enhanced heat and mass transfer, precise control, and reduced footprint compared to conventional reactor designs.

Heat Integration

Process intensification enhances heat integration by maximizing energy recovery and minimizing utility consumption compared to conventional design.

Modular Processing

Modular processing in process intensification enhances efficiency and scalability by integrating compact, flexible units, contrasting with the rigid, large-scale infrastructure typical of conventional design.

Reactive Distillation

Reactive distillation intensifies chemical processes by combining reaction and separation in a single unit, significantly reducing equipment size and energy consumption compared to conventional design, which separates these steps into distinct units.

High-gravity Technologies

High-gravity technologies enhance process intensification by significantly increasing mass and heat transfer rates compared to conventional designs, resulting in improved efficiency and reduced equipment size.

Process Intensification Factors (PIF)

Process Intensification Factors (PIF) quantify efficiency gains by comparing metrics such as energy consumption, equipment size, and production capacity between intensified and conventional process designs.

Multi-functional Reactors

Multi-functional reactors enhance process intensification by integrating reaction, separation, and heat transfer within a single unit, significantly outperforming conventional designs in efficiency and scalability.

Downstream Footprint Reduction

Process Intensification reduces downstream footprint by integrating unit operations, minimizing equipment size, and enhancing process efficiency compared to conventional design.

Process Safety Enhancement

Process Intensification enhances process safety by reducing equipment size, minimizing hazardous inventories, and improving heat and mass transfer rates compared to conventional design.

Intensified Mass Transfer

Process intensification enhances mass transfer efficiency through innovative designs such as microreactors and high-gravity fields, significantly outperforming conventional designs in transfer rates and energy consumption.

Process Intensification vs Conventional Design Infographic

njnir.com

njnir.com