CFD simulation enables detailed visualization and analysis of fluid flow and heat transfer phenomena that are often challenging to capture experimentally in chemical engineering processes. Experimental modeling provides essential validation data and real-world conditions but can be limited by scale, cost, and measurement constraints. Integrating CFD simulations with experimental results enhances accuracy, optimizes process designs, and reduces development time in chemical engineering applications.

Table of Comparison

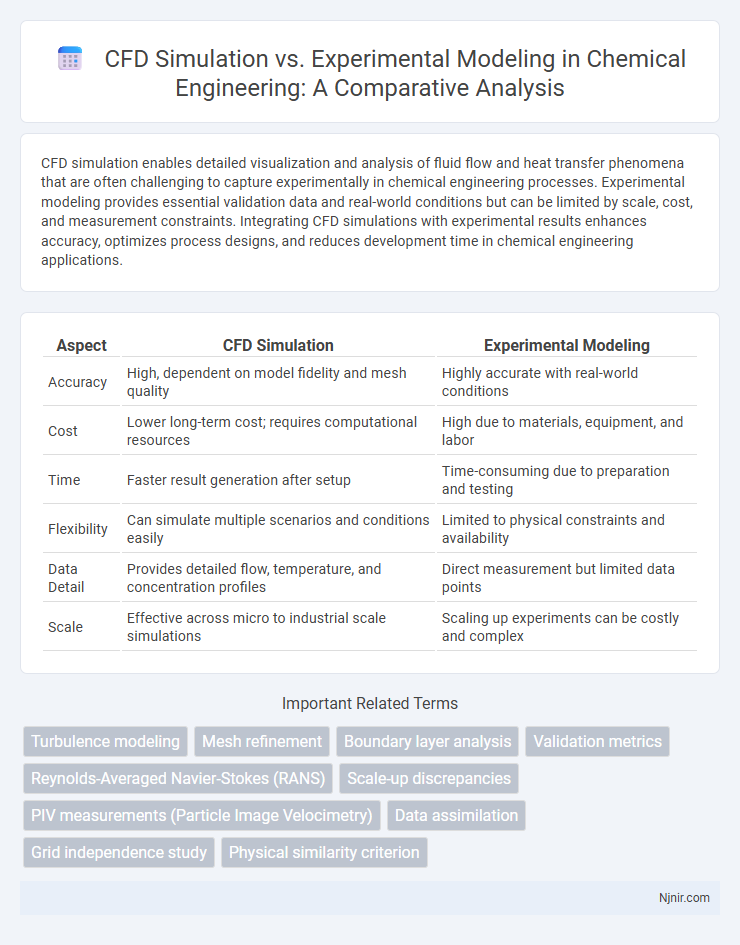

| Aspect | CFD Simulation | Experimental Modeling |

|---|---|---|

| Accuracy | High, dependent on model fidelity and mesh quality | Highly accurate with real-world conditions |

| Cost | Lower long-term cost; requires computational resources | High due to materials, equipment, and labor |

| Time | Faster result generation after setup | Time-consuming due to preparation and testing |

| Flexibility | Can simulate multiple scenarios and conditions easily | Limited to physical constraints and availability |

| Data Detail | Provides detailed flow, temperature, and concentration profiles | Direct measurement but limited data points |

| Scale | Effective across micro to industrial scale simulations | Scaling up experiments can be costly and complex |

Introduction to CFD Simulation and Experimental Modeling

CFD simulation leverages computational algorithms and numerical analysis to predict fluid flow, heat transfer, and related phenomena, offering detailed insights into complex systems without physical prototypes. Experimental modeling involves physical testing and measurement in controlled environments to validate theories and observe real-world behavior, providing empirical data crucial for accuracy. Both methods complement each other, with CFD enabling cost-effective preliminary analysis and experimentation ensuring reliability through tangible evidence.

Fundamental Principles of CFD in Chemical Engineering

CFD simulation in chemical engineering utilizes the Navier-Stokes equations to model fluid flow, heat transfer, and mass transport at a detailed level, enabling prediction of complex reactive and multiphase systems. Experimental modeling provides empirical data but often faces limitations in resolution and scale, making it challenging to capture intricate flow dynamics accurately. Combining CFD with experimental validation enhances process optimization by leveraging computational precision and real-world observations in chemical reactor design and safety analysis.

Experimental Modeling Techniques in Chemical Processes

Experimental modeling techniques in chemical processes provide crucial data on reaction kinetics, mass transfer, and heat exchange by simulating real-world conditions through laboratory-scale reactors, pilot plants, and flow visualization methods. These techniques enable direct measurement of variables such as temperature, concentration, and pressure, ensuring accurate validation of theoretical predictions and computational fluid dynamics (CFD) simulations. Integrating experimental results with CFD enhances process optimization, scale-up accuracy, and safety assessment in chemical engineering applications.

Advantages of CFD Simulation in Chemical Engineering

CFD simulation in chemical engineering offers precise control over complex fluid dynamics and reaction kinetics, enabling detailed visualization of flow patterns and heat transfer that are often difficult to capture experimentally. It significantly reduces costs and time by allowing virtual testing of various process configurations and scaling scenarios without the need for physical prototypes. Enhanced data accuracy from CFD models facilitates optimization of chemical reactors and separation processes, improving safety and efficiency in industrial applications.

Limitations of CFD Simulation Approaches

CFD simulation often faces limitations such as mesh dependency, which can affect the accuracy and stability of results. Turbulence modeling challenges and assumptions in boundary conditions may lead to discrepancies when compared to experimental data. Computational cost and resource intensity further constrain the ability to simulate complex, real-world fluid dynamics accurately.

Benefits and Challenges of Experimental Modeling

Experimental modeling offers direct measurement of physical phenomena, providing highly accurate and real-world data for validating theoretical models or simulations. Challenges include high costs, time-intensive setups, and potential limitations in replicating extreme or hazardous conditions safely. Complex systems may exhibit scale effects and measurement errors, requiring careful calibration and interpretation of experimental results.

Comparative Analysis: Accuracy and Reliability

CFD simulation offers high precision in fluid dynamics analysis by solving complex mathematical models, enabling detailed visualization of flow patterns often difficult to capture experimentally. Experimental modeling provides empirical data reflecting real-world conditions, which help validate and calibrate CFD results, ensuring reliability despite potential measurement errors and scale limitations. Combining both approaches enhances overall accuracy, as CFD predicts scenarios beyond experimental reach while experiments confirm simulation validity.

Cost and Time Considerations: CFD vs Experimental Methods

CFD simulation significantly reduces costs by eliminating the need for physical prototypes, materials, and extensive laboratory setups, while delivering rapid analysis through automated computations. Experimental modeling often involves high expenses due to equipment, maintenance, and skilled labor, with time-consuming setup and iterative testing phases. For projects emphasizing budget efficiency and faster turnaround, CFD offers superior advantages compared to traditional experimental methods.

Integration of CFD and Experimental Data

Integration of CFD simulation and experimental modeling enhances the accuracy of fluid dynamics analysis by combining numerical predictions with real-world measurements. Using experimental data for validating and calibrating CFD models reduces uncertainties and improves turbulence modeling fidelity. Hybrid approaches leverage sensor data and particle image velocimetry (PIV) to refine boundary conditions and optimize aerodynamic designs.

Future Trends in Chemical Engineering Modeling

CFD simulation is rapidly advancing with the integration of artificial intelligence and machine learning algorithms, enabling more accurate and faster predictions of complex chemical processes. Experimental modeling remains crucial for validating simulations and providing real-world data but increasingly relies on automated and high-throughput techniques to enhance efficiency. Future trends emphasize hybrid approaches that combine CFD simulations with experimental data, improving scalability and optimizing chemical reactor designs in sustainable manufacturing.

Turbulence modeling

CFD simulation enables detailed turbulence modeling through various numerical methods such as Large Eddy Simulation (LES) and Reynolds-Averaged Navier-Stokes (RANS), providing precise flow predictions compared to the costlier and time-consuming experimental modeling.

Mesh refinement

Mesh refinement in CFD simulation critically enhances accuracy by resolving complex flow details, whereas experimental modeling relies on physical measurements without the ability to adjust computational grid resolution.

Boundary layer analysis

CFD simulation provides detailed boundary layer analysis through precise velocity and temperature gradient calculations, offering enhanced spatial resolution and flexibility compared to experimental modeling methods like hot-wire anemometry or particle image velocimetry.

Validation metrics

CFD simulation validation metrics such as root mean square error (RMSE), coefficient of determination (R2), and normalized mean absolute error (NMAE) quantitatively compare simulated results with experimental modeling data to ensure accuracy and reliability.

Reynolds-Averaged Navier-Stokes (RANS)

Reynolds-Averaged Navier-Stokes (RANS) CFD simulations provide efficient, time- and cost-effective turbulence modeling with reliable averaged flow predictions compared to detailed but expensive and time-consuming experimental modeling.

Scale-up discrepancies

CFD simulation often underestimates scale-up discrepancies due to idealized boundary conditions and simplified turbulence models, whereas experimental modeling captures complex scale-dependent phenomena and real-world variability more accurately.

PIV measurements (Particle Image Velocimetry)

CFD simulations provide detailed flow field predictions that complement PIV measurements by validating velocity vectors and turbulence structures within experimental fluid dynamics studies.

Data assimilation

CFD simulation enhances experimental modeling accuracy by integrating real-time data assimilation to dynamically update boundary conditions and improve predictive reliability.

Grid independence study

Grid independence study in CFD simulation ensures accurate, stable results by verifying that further mesh refinement does not significantly affect the outcome, unlike experimental modeling which relies on physical measurements but cannot isolate grid effects.

Physical similarity criterion

Physical similarity criterion in CFD simulation ensures accurate replication of experimental modeling by matching dimensionless numbers like Reynolds and Mach for reliable fluid flow predictions.

CFD simulation vs experimental modeling Infographic

njnir.com

njnir.com