Plastic pyrolysis breaks down complex polymer chains into valuable hydrocarbon fuels and chemical feedstocks through thermal decomposition, offering a solution for mixed and contaminated plastics that mechanical recycling cannot process efficiently. Mechanical recycling, on the other hand, involves the physical reprocessing of sorted plastics into new products, preserving polymer integrity but limited by contamination and polymer degradation over successive cycles. Optimizing plastic waste management requires integrating both methods to maximize material recovery and reduce environmental impact.

Table of Comparison

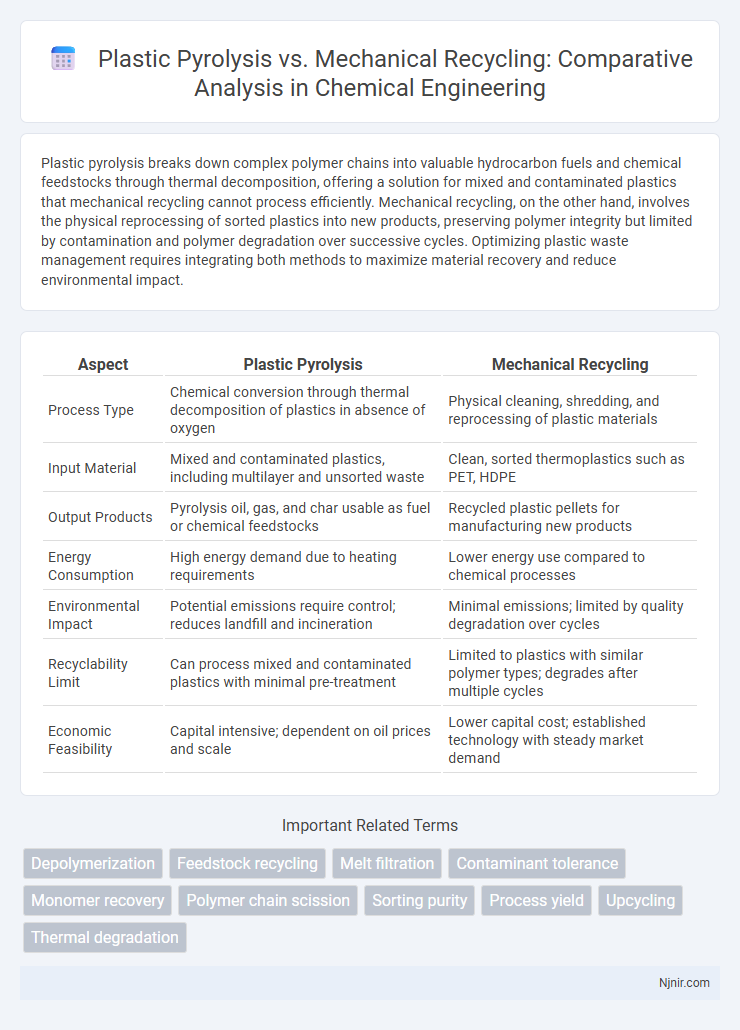

| Aspect | Plastic Pyrolysis | Mechanical Recycling |

|---|---|---|

| Process Type | Chemical conversion through thermal decomposition of plastics in absence of oxygen | Physical cleaning, shredding, and reprocessing of plastic materials |

| Input Material | Mixed and contaminated plastics, including multilayer and unsorted waste | Clean, sorted thermoplastics such as PET, HDPE |

| Output Products | Pyrolysis oil, gas, and char usable as fuel or chemical feedstocks | Recycled plastic pellets for manufacturing new products |

| Energy Consumption | High energy demand due to heating requirements | Lower energy use compared to chemical processes |

| Environmental Impact | Potential emissions require control; reduces landfill and incineration | Minimal emissions; limited by quality degradation over cycles |

| Recyclability Limit | Can process mixed and contaminated plastics with minimal pre-treatment | Limited to plastics with similar polymer types; degrades after multiple cycles |

| Economic Feasibility | Capital intensive; dependent on oil prices and scale | Lower capital cost; established technology with steady market demand |

Introduction to Plastic Waste Management

Plastic pyrolysis converts plastic waste into valuable fuels and chemicals through thermal decomposition at high temperatures in an oxygen-free environment, offering a solution for mixed and contaminated plastics that mechanical recycling cannot process efficiently. Mechanical recycling involves sorting, cleaning, and remelting plastic waste into new products, but it is limited by the degradation of plastic quality and contamination levels. Effective plastic waste management increasingly relies on integrating both methods to maximize material recovery and reduce environmental impact.

Overview of Mechanical Recycling Processes

Mechanical recycling involves the physical processing of plastic waste through sorting, cleaning, shredding, and melting to produce reusable plastic pellets. This process retains the polymer structure but can degrade material quality over multiple cycles due to thermal and mechanical stress. Compared to plastic pyrolysis, mechanical recycling is more energy-efficient and cost-effective for clean, single-type plastics but faces challenges with mixed or contaminated waste streams.

Fundamentals of Plastic Pyrolysis Technology

Plastic pyrolysis technology involves thermally decomposing plastic waste at high temperatures in an oxygen-free environment to convert polymers into valuable fuels and raw materials. Unlike mechanical recycling, which physically processes plastics by melting and remolding, pyrolysis breaks down molecular structures, enabling the recycling of mixed and contaminated plastics that mechanical methods cannot handle effectively. Key parameters affecting pyrolysis outcomes include temperature, residence time, and catalyst presence, which influence product yield and quality, making it a versatile solution for plastic waste valorization.

Feedstock Requirements: Mechanical vs Pyrolysis

Mechanical recycling requires clean, sorted plastic waste, predominantly single-type polymers like PET and HDPE, to maintain material integrity and quality. Plastic pyrolysis can process mixed, contaminated, and multilayer plastics, converting them into valuable fuels and chemicals despite feedstock variability. Pyrolysis tolerates heterogeneous feedstock with minimal pre-sorting, whereas mechanical recycling demands strict feedstock cleanliness and homogeneity to avoid degradation.

Product Output and Value Chains

Plastic pyrolysis converts mixed plastic waste into valuable hydrocarbons like oils, gases, and char, enabling feedstock flexibility and integration into chemical refineries, enhancing product value chains. Mechanical recycling produces lower-value recycled plastics limited by polymer degradation and sorting requirements, primarily reintegrating materials into packaging and non-durable goods markets. The higher versatility and energy density of pyrolysis outputs support broader industrial applications, driving improved economic returns and circular economy potential compared to conventional mechanical recycling.

Environmental Impact Assessment

Plastic pyrolysis and mechanical recycling differ significantly in environmental impact assessments; pyrolysis converts waste plastics into valuable fuels but generates greenhouse gases and potential toxic emissions, requiring strict emission controls to minimize atmospheric pollution. Mechanical recycling preserves plastic polymers without chemical alteration, reducing energy consumption and limiting carbon footprint, though it faces challenges with contamination and polymer degradation limiting material quality. Lifecycle analyses indicate mechanical recycling generally offers a lower environmental impact due to reduced emissions and resource recovery efficiency compared to pyrolysis processes.

Energy Consumption and Carbon Footprint

Plastic pyrolysis typically consumes more energy than mechanical recycling due to high-temperature processes required to thermally decompose plastics into fuels or monomers. Mechanical recycling, which involves cleaning, shredding, and remelting plastics, generally exhibits a lower carbon footprint because it preserves polymer structures and avoids combustion-related emissions. Studies indicate mechanical recycling can reduce energy consumption by up to 80% compared to virgin plastic production, while pyrolysis often results in higher greenhouse gas emissions despite offering solutions for mixed or contaminated plastics.

Economic Feasibility and Scalability

Plastic pyrolysis offers higher economic feasibility in processing mixed and contaminated plastic waste due to its ability to convert various polymer types into valuable fuel products, whereas mechanical recycling requires clean, sorted plastics, limiting its cost-effectiveness. Scalability is more achievable with pyrolysis plants as they can handle large volumes of diverse plastics without extensive pretreatment, while mechanical recycling systems face challenges in scale-up given their dependence on material purity and fragmentation processes. Investment costs for pyrolysis technology tend to be higher initially but yield greater long-term economic returns through fuel production, contrasting with the lower upfront costs but limited market value of mechanically recycled plastics.

Policy and Regulatory Considerations

Plastic pyrolysis faces complex policy and regulatory challenges due to its classification as a chemical recycling process, often triggering stricter environmental and safety standards compared to mechanical recycling, which is widely accepted and supported by established waste management frameworks. Governments and regulatory bodies are increasingly scrutinizing pyrolysis for potential emissions and byproducts, necessitating comprehensive permits and compliance with air quality and hazardous waste regulations. Mechanical recycling benefits from clearer regulatory guidelines, subsidies, and circular economy policies that prioritize lowering contamination and improving collection systems to enhance material recovery rates.

Future Prospects and Innovations in Plastic Recycling

Plastic pyrolysis offers a promising future by converting mixed plastic waste into valuable fuels and raw materials, addressing limitations of mechanical recycling which struggles with contamination and polymer degradation. Innovations in catalytic pyrolysis and advanced sorting technologies are enhancing efficiency and product quality, potentially making chemical recycling more economically viable and environmentally sustainable. Emerging trends include integrating AI-driven process optimization and scaling decentralized pyrolysis units to complement mechanical recycling infrastructure, promoting a circular plastic economy.

Depolymerization

Depolymerization in plastic pyrolysis breaks down polymers into monomers for chemical reuse, offering higher material recovery compared to mechanical recycling, which physically shreds plastics without altering their molecular structure.

Feedstock recycling

Feedstock recycling through plastic pyrolysis chemically converts mixed and contaminated plastic waste into valuable hydrocarbons, offering higher flexibility and recovery rates compared to mechanical recycling, which primarily processes clean, single-polymer streams into lower-quality materials.

Melt filtration

Melt filtration in plastic pyrolysis optimizes the removal of contaminants from pyrolyzed oils, offering a more effective purification compared to mechanical recycling, which primarily processes solid plastics without addressing molecular impurities.

Contaminant tolerance

Plastic pyrolysis tolerates higher contaminant levels than mechanical recycling, enabling efficient processing of mixed and contaminated plastic waste streams.

Monomer recovery

Plastic pyrolysis enables higher monomer recovery rates compared to mechanical recycling by breaking down polymers into original monomers suitable for virgin-quality plastic production.

Polymer chain scission

Plastic pyrolysis involves polymer chain scission through thermal decomposition breaking long polymer chains into smaller molecules, whereas mechanical recycling preserves polymer chain integrity by physically reprocessing plastics without altering their chemical structure.

Sorting purity

Plastic pyrolysis tolerates mixed and lower-purity plastic feedstocks, while mechanical recycling requires high sorting purity to maintain material quality and performance.

Process yield

Plastic pyrolysis typically achieves higher process yield by converting mixed plastic waste into valuable liquid fuels, whereas mechanical recycling often results in lower yield due to degradation and contamination limitations.

Upcycling

Plastic pyrolysis transforms mixed plastic waste into valuable fuels and chemicals, enabling higher-value upcycling compared to mechanical recycling, which primarily downcycles plastics into lower-quality materials.

Thermal degradation

Plastic pyrolysis involves thermal degradation by breaking down polymers at high temperatures in an oxygen-free environment, yielding valuable hydrocarbons, whereas mechanical recycling retains polymer structure by melting and reshaping without chemical change.

plastic pyrolysis vs mechanical recycling Infographic

njnir.com

njnir.com