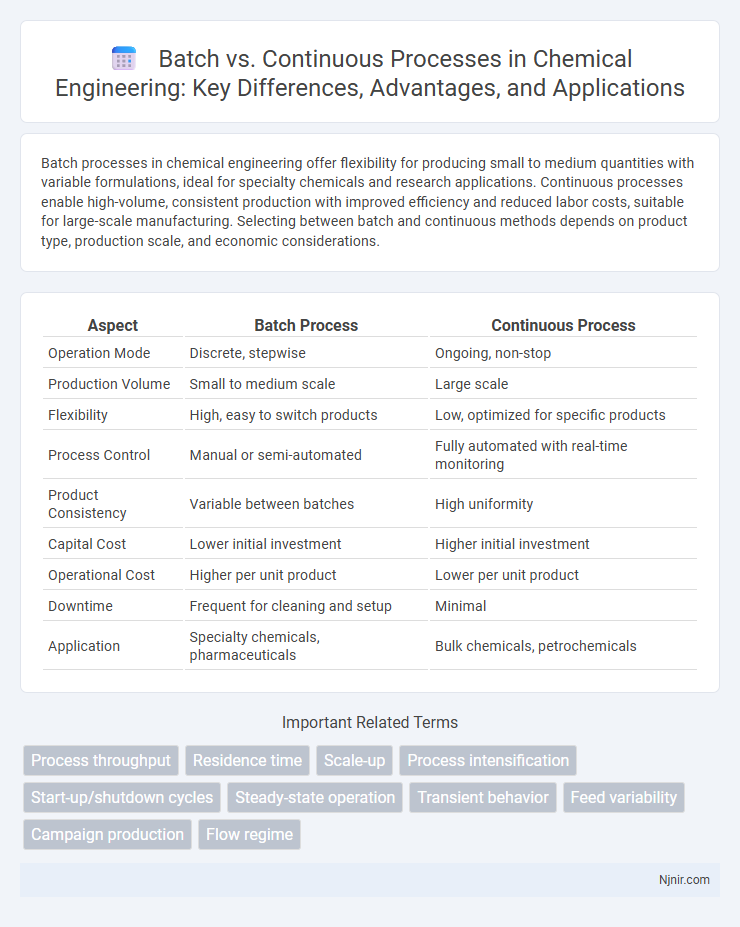

Batch processes in chemical engineering offer flexibility for producing small to medium quantities with variable formulations, ideal for specialty chemicals and research applications. Continuous processes enable high-volume, consistent production with improved efficiency and reduced labor costs, suitable for large-scale manufacturing. Selecting between batch and continuous methods depends on product type, production scale, and economic considerations.

Table of Comparison

| Aspect | Batch Process | Continuous Process |

|---|---|---|

| Operation Mode | Discrete, stepwise | Ongoing, non-stop |

| Production Volume | Small to medium scale | Large scale |

| Flexibility | High, easy to switch products | Low, optimized for specific products |

| Process Control | Manual or semi-automated | Fully automated with real-time monitoring |

| Product Consistency | Variable between batches | High uniformity |

| Capital Cost | Lower initial investment | Higher initial investment |

| Operational Cost | Higher per unit product | Lower per unit product |

| Downtime | Frequent for cleaning and setup | Minimal |

| Application | Specialty chemicals, pharmaceuticals | Bulk chemicals, petrochemicals |

Introduction to Batch and Continuous Processes

Batch processes involve producing goods in specific, controlled quantities where materials are processed in discrete steps, allowing flexibility in product variation and customization. Continuous processes operate nonstop, with raw materials constantly moving through production lines to achieve high volume efficiency and consistent product quality. Selecting between batch and continuous systems depends on factors like production scale, product complexity, and demand variability.

Key Differences Between Batch and Continuous Operations

Batch operations involve processing a finite amount of material in discrete, separate steps, allowing for flexibility and customization in production but often resulting in longer downtime between cycles. Continuous operations maintain an uninterrupted flow of materials through the system, optimizing efficiency and consistency in large-scale production while requiring significant initial investment and control complexity. Key differences include production scale, process control, downtime frequency, and suitability for product variation, with batch favoring small volumes and flexibility, and continuous excelling in high-volume, uniform output.

Advantages of Batch Processing

Batch processing offers advantages such as improved resource utilization by processing large volumes of data simultaneously, which reduces system idle time and overhead costs. It enhances fault tolerance because errors can be detected and corrected before moving on to the next batch, minimizing the impact on overall operations. Scalability is also a key benefit, allowing for easy adjustment of batch sizes to handle varying workloads efficiently in environments like data analytics and financial transactions.

Advantages of Continuous Processing

Continuous processing offers enhanced productivity with the ability to operate 24/7, significantly reducing downtime and increasing overall throughput compared to batch processing. This method ensures consistent product quality by maintaining steady-state conditions, minimizing variations associated with start-stop cycles in batch operations. Energy efficiency is improved through optimized process control, resulting in lower operational costs and reduced waste generation.

Process Design Considerations

Batch process design requires flexibility to handle variable recipe sizes and frequent changeovers, optimizing for product variety and small to medium production volumes. Continuous process design focuses on steady-state operation with optimized flow rates and minimal downtime, ideal for large-scale, consistent production with high throughput. Equipment selection and control strategies must align with the intended process scale and product specifications to ensure operational efficiency and product quality.

Applications in Chemical Manufacturing

Batch chemical manufacturing excels in producing specialty chemicals, pharmaceuticals, and customized products requiring precise control over reaction times and conditions. Continuous chemical manufacturing is preferred for large-scale production of commodity chemicals, petrochemicals, and polymers due to its efficiency, consistent quality, and reduced operational costs. The choice between batch and continuous processes depends on product complexity, volume requirements, and flexibility needed in chemical production.

Scalability and Flexibility Comparison

Batch processing offers high flexibility by allowing customization of individual job parameters but often faces scalability limitations due to resource contention and longer processing times. Continuous processing excels in scalability as it handles large data volumes in real-time through automated pipelines, enabling faster throughput and consistent output. The choice depends on operational demands: batch suits variable workloads with complex logic, while continuous supports rapid scaling for steady, high-frequency data streams.

Cost and Energy Efficiency Analysis

Batch processing often incurs higher energy consumption and operational costs due to frequent start-ups and shutdowns, causing inefficiencies in resource utilization. Continuous processing optimizes energy use by maintaining steady-state operations, leading to lower per-unit production costs and reduced waste generation. Economic analysis highlights that industries with large-scale, consistent production demands benefit significantly from continuous processing in terms of cost savings and energy efficiency.

Safety and Environmental Impact

Batch processing allows for better containment and control of hazardous materials, reducing the risk of accidental releases and exposure, which enhances safety protocols. Continuous processing minimizes waste generation and energy consumption through steady-state operations, leading to a lower environmental footprint. Implementing robust monitoring systems in both batch and continuous processes is essential to detect deviations and prevent environmental contamination.

Choosing the Right Process for Your Application

Choosing the right process--batch or continuous--depends on factors like production volume, product consistency, and operational flexibility. Batch processing suits small to medium-scale production requiring frequent changeovers and diverse product lines. Continuous processing excels in high-volume, uniform production environments demanding consistent quality and efficiency.

Process throughput

Continuous processing achieves higher process throughput than batch processing by maintaining uninterrupted production flow and minimizing downtime.

Residence time

Residence time in batch processing is fixed and uniform for all materials, whereas continuous processing features variable residence times depending on flow rates and reactor design.

Scale-up

Batch processes offer flexibility for small to medium-scale production, while continuous processes enable efficient scale-up for large-volume manufacturing with consistent product quality.

Process intensification

Continuous processing enhances process intensification by enabling consistent operation, improved heat and mass transfer, and higher throughput compared to traditional batch methods.

Start-up/shutdown cycles

Batch processes experience frequent start-up and shutdown cycles causing higher operational costs, whereas continuous processes maintain steady production with minimal start-up and shutdown, enhancing efficiency and reducing downtime.

Steady-state operation

Continuous processes maintain steady-state operation by running non-stop, ensuring consistent product quality and efficiency, whereas batch processes operate intermittently, leading to variable conditions and potential productivity fluctuations.

Transient behavior

Batch processes exhibit pronounced transient behavior due to periodic start-stop cycles, while continuous processes maintain steady-state conditions with minimal transient fluctuations.

Feed variability

Batch processes handle feed variability by processing fixed quantities with controlled composition, while continuous processes require consistent feed quality to maintain steady-state operation and product uniformity.

Campaign production

Batch campaign production processes multiple marketing materials simultaneously for efficiency, while continuous campaign production delivers real-time, ongoing content tailored to dynamic audience interactions.

Flow regime

Batch processes operate under unsteady flow regimes with variable fluid dynamics, while continuous processes maintain steady flow regimes ensuring consistent fluid behavior.

Batch vs Continuous Infographic

njnir.com

njnir.com