Process intensification in chemical engineering emphasizes designing more efficient, compact, and sustainable processes by integrating unit operations and enhancing mass and heat transfer. Scale-up traditionally involves enlarging laboratory-scale processes to industrial production, often leading to increased equipment size and energy consumption. Intensification offers advantages over scale-up by reducing footprint, improving reaction rates, and minimizing waste generation while maintaining or enhancing process performance.

Table of Comparison

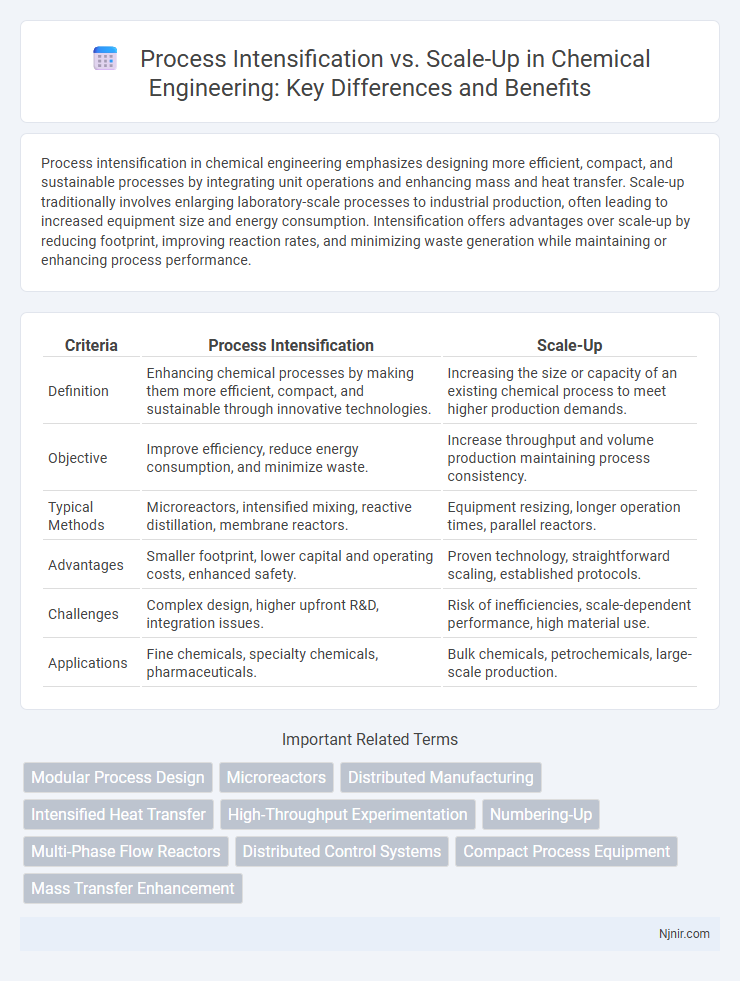

| Criteria | Process Intensification | Scale-Up |

|---|---|---|

| Definition | Enhancing chemical processes by making them more efficient, compact, and sustainable through innovative technologies. | Increasing the size or capacity of an existing chemical process to meet higher production demands. |

| Objective | Improve efficiency, reduce energy consumption, and minimize waste. | Increase throughput and volume production maintaining process consistency. |

| Typical Methods | Microreactors, intensified mixing, reactive distillation, membrane reactors. | Equipment resizing, longer operation times, parallel reactors. |

| Advantages | Smaller footprint, lower capital and operating costs, enhanced safety. | Proven technology, straightforward scaling, established protocols. |

| Challenges | Complex design, higher upfront R&D, integration issues. | Risk of inefficiencies, scale-dependent performance, high material use. |

| Applications | Fine chemicals, specialty chemicals, pharmaceuticals. | Bulk chemicals, petrochemicals, large-scale production. |

Introduction to Process Intensification and Scale-Up

Process intensification involves designing smaller, more efficient equipment and processes to enhance productivity and reduce energy consumption within chemical manufacturing. Scale-up focuses on increasing batch or production size by replicating and enlarging existing processes while maintaining product quality and process stability. Both strategies aim to improve manufacturing efficiency but differ in their approach to equipment design and operational scale adjustments.

Fundamental Principles of Process Intensification

Process intensification focuses on enhancing chemical processes by integrating operations, increasing mass and heat transfer rates, and reducing energy consumption, fundamentally optimizing reactor design and process units for higher efficiency. Key principles include minimizing equipment size through intensified mixing and reaction conditions, utilizing novel technologies such as microreactors and membrane reactors, and achieving more effective separation methods. Unlike traditional scale-up, which enlarges existing processes linearly, process intensification redefines process configurations to improve safety, sustainability, and economic viability.

Key Drivers for Scale-Up in Chemical Engineering

Key drivers for scale-up in chemical engineering include achieving consistent product quality, increasing production capacity, and ensuring process safety and environmental compliance at larger volumes. Scale-up challenges often involve maintaining heat and mass transfer efficiencies, controlling reaction kinetics, and optimizing equipment design to handle increased throughput. Process intensification aims to address these issues by enhancing process efficiency, reducing equipment size, and minimizing energy consumption, enabling more sustainable and cost-effective scale-up strategies.

Comparative Analysis: Process Intensification vs. Scale-Up

Process intensification enhances chemical manufacturing by integrating innovative technologies that increase efficiency, throughput, and sustainability within existing reactor volumes. Scale-up focuses on enlarging equipment size to increase production capacity but often requires significant capital investment and may introduce challenges in maintaining process control and product quality. Comparative analysis reveals that process intensification offers reduced footprint and energy consumption with improved reaction kinetics, whereas scale-up provides straightforward capacity increases but may compromise operational flexibility.

Impact on Energy Efficiency and Sustainability

Process intensification significantly enhances energy efficiency by reducing equipment size and minimizing energy consumption through integrated, high-performance unit operations. In contrast, traditional scale-up often leads to increased energy demands and resource use due to larger, less optimized equipment and extended processing times. Emphasizing intensified processes drives sustainable manufacturing by lowering emissions, reducing waste, and promoting resource-efficient production methods.

Equipment Design Considerations

Process intensification emphasizes designing compact, multifunctional equipment to enhance efficiency, reduce energy consumption, and minimize environmental impact, often integrating multiple unit operations into a single device. Scale-up focuses on enlarging equipment size to increase production capacity while maintaining process consistency, requiring careful consideration of heat and mass transfer, fluid dynamics, and mechanical robustness to avoid performance loss. Equipment design considerations in process intensification prioritize innovation in geometry and modularity, whereas scale-up demands thorough validation of operational parameters to ensure scalability and reliability.

Challenges and Limitations of Each Approach

Process intensification faces challenges such as complex equipment design, increased risk of operational instability, and difficulties in heat and mass transfer at micro scales. Scale-up limitations include non-linear scaling effects, costly pilot testing, and potential loss of efficiency due to changes in fluid dynamics and mixing patterns. Both approaches require careful consideration of material properties, energy consumption, and process control to ensure consistent product quality and safety.

Case Studies in Industrial Applications

Process intensification enhances efficiency by integrating innovative technologies such as microreactors and advanced heat exchangers, leading to smaller equipment footprints and higher productivity in chemical manufacturing. Scale-up in industrial applications often encounters challenges related to maintaining reaction kinetics and mass transfer rates observed in laboratory conditions, as demonstrated by case studies in pharmaceutical and petrochemical industries. Successful examples include the intensified production of specialty chemicals where microfluidics enabled improved selectivity, contrasted with traditional scale-up approaches that required extensive pilot plant trials to achieve similar yields.

Future Trends in Process Development

Future trends in process development emphasize process intensification techniques such as microreactors, continuous flow systems, and advanced heat integration to enhance efficiency and reduce environmental impact. These innovations enable more flexible, modular production units that outperform traditional scale-up methods in speed and resource utilization. Integration of digital twin technology and AI-driven process optimization further accelerates development, driving a shift from conventional scale-up to smarter, intensified processes.

Strategic Decision-Making in Process Selection

Process intensification enhances efficiency by integrating multiple unit operations into a single intensified process, reducing energy use and footprint compared to conventional scale-up methods that expand equipment size to increase capacity. Strategic decision-making in process selection involves evaluating factors such as production volume, capital expenditure, operational costs, and environmental impact to choose between intensification and scale-up approaches. Process intensification is favored for innovative, flexible manufacturing with high resource efficiency, while scale-up suits established, large-scale continuous production where proven reliability is critical.

Modular Process Design

Modular process design enhances process intensification by enabling scalable, flexible units that reduce complexity and cost compared to traditional large-scale scale-up.

Microreactors

Microreactors enable process intensification by enhancing heat and mass transfer rates at a microscale, offering superior control and safety compared to traditional scale-up methods in chemical manufacturing.

Distributed Manufacturing

Distributed manufacturing enhances process intensification by enabling localized, modular production units that reduce scale-up challenges and improve flexibility in chemical and pharmaceutical industries.

Intensified Heat Transfer

Intensified heat transfer enhances process intensification by significantly improving thermal efficiency and reducing equipment size compared to traditional scale-up methods.

High-Throughput Experimentation

High-Throughput Experimentation accelerates process intensification by enabling rapid screening and optimization of reactions at a smaller scale, reducing the challenges associated with traditional scale-up methods.

Numbering-Up

Numbering-up, as a process intensification strategy, enhances production capacity by operating multiple smaller units in parallel instead of traditional scale-up, enabling improved control, scalability, and safety in chemical manufacturing.

Multi-Phase Flow Reactors

Multi-Phase Flow Reactors enable process intensification by improving mass and heat transfer efficiencies on a smaller footprint, offering scalable advantages over traditional scale-up methods that often require larger equipment with diminished performance.

Distributed Control Systems

Distributed Control Systems enhance process intensification by enabling precise real-time monitoring and control at smaller scales, reducing complexity and improving scalability compared to traditional large-scale scale-up approaches.

Compact Process Equipment

Compact process equipment enables efficient process intensification by reducing footprint and energy consumption, offering superior alternatives to traditional scale-up methods.

Mass Transfer Enhancement

Process intensification enhances mass transfer rates by utilizing advanced equipment and innovative designs, whereas scale-up relies on enlarging conventional systems, often facing efficiency losses in mass transfer performance.

process intensification vs scale-up Infographic

njnir.com

njnir.com