Microreactors offer enhanced heat and mass transfer rates due to their high surface-to-volume ratio, enabling precise control over reaction conditions and superior safety profiles. Macroreactors, while capable of handling larger batch volumes, often face challenges in achieving uniform temperature distribution and efficient mixing, which can limit reaction efficiency and scalability. The choice between microreactors and macroreactors depends on process requirements such as production scale, reaction kinetics, and operational flexibility.

Table of Comparison

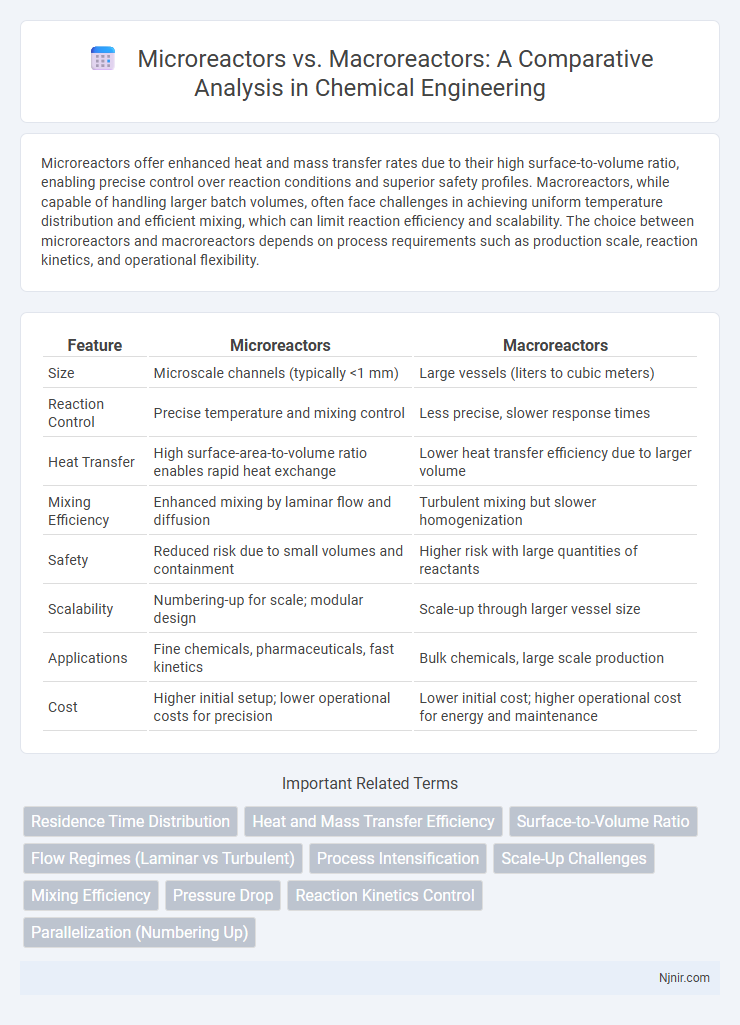

| Feature | Microreactors | Macroreactors |

|---|---|---|

| Size | Microscale channels (typically <1 mm) | Large vessels (liters to cubic meters) |

| Reaction Control | Precise temperature and mixing control | Less precise, slower response times |

| Heat Transfer | High surface-area-to-volume ratio enables rapid heat exchange | Lower heat transfer efficiency due to larger volume |

| Mixing Efficiency | Enhanced mixing by laminar flow and diffusion | Turbulent mixing but slower homogenization |

| Safety | Reduced risk due to small volumes and containment | Higher risk with large quantities of reactants |

| Scalability | Numbering-up for scale; modular design | Scale-up through larger vessel size |

| Applications | Fine chemicals, pharmaceuticals, fast kinetics | Bulk chemicals, large scale production |

| Cost | Higher initial setup; lower operational costs for precision | Lower initial cost; higher operational cost for energy and maintenance |

Introduction to Microreactors and Macroreactors

Microreactors feature microscale channels allowing precise control over reaction conditions, enhancing heat and mass transfer rates compared to traditional macroreactors. Macroreactors, commonly used in large-scale industrial processes, operate with bulk volumes and rely on mixing and heat transfer across larger interfaces, which can limit reaction efficiency and scalability. The fundamental difference lies in the scale and design, where microreactors offer improved safety, faster reaction times, and higher selectivity due to their compact structure and superior fluid dynamics.

Fundamental Principles and Design

Microreactors operate on the principle of enhanced surface-to-volume ratios, enabling superior heat and mass transfer rates compared to macroreactors, which rely on larger scale mixing and batch processing. The compact design of microreactors facilitates precise control over reaction parameters, minimizing diffusion limitations and enabling safer handling of hazardous materials. Macroreactor design focuses on robust agitation and temperature control systems to ensure homogeneity, often involving complex scale-up challenges due to inefficient heat dissipation and mixing inefficiencies.

Material Selection and Construction

Microreactors utilize advanced materials such as silicon, glass, and specialized polymers to ensure precise chemical resistance, thermal stability, and miniaturized fabrication, enabling rapid heat and mass transfer. Macroreactors typically employ stainless steel or glass-lined steel for robust construction, balancing cost-effectiveness with durability under high pressure and temperature conditions. Material selection in microreactors prioritizes microfluidic compatibility and corrosion resistance, while macroreactors focus on structural integrity and long-term operational reliability.

Reaction Kinetics and Process Intensification

Microreactors enable enhanced reaction kinetics through superior mass and heat transfer rates compared to macroreactors, leading to faster reaction times and higher selectivity. The increased surface-to-volume ratio in microreactors intensifies processes by minimizing temperature gradients and improving mixing efficiency, which reduces side reactions and enhances yield. Process intensification in microreactors also allows for safer handling of hazardous reactions due to better control over reaction conditions and scalability through numbering-up strategies.

Heat and Mass Transfer Efficiency

Microreactors exhibit significantly higher heat and mass transfer efficiency compared to macroreactors due to their increased surface-to-volume ratio, enabling rapid heat dissipation and uniform temperature control. Enhanced mixing at the microscale minimizes concentration gradients, resulting in improved reaction selectivity and faster kinetics. This superior transfer efficiency in microreactors reduces hot spots and enhances overall process safety and scalability.

Scale-Up and Throughput Considerations

Microreactors offer enhanced control over reaction conditions, enabling precise temperature and mixing profiles critical for scale-up. Their small volume facilitates rapid heat and mass transfer, improving safety and product consistency, but throughput remains limited compared to macroreactors. Scaling up typically involves numbering-up strategies, where multiple microreactors operate in parallel to achieve industrial-scale production without compromising performance.

Safety and Risk Management

Microreactors offer enhanced safety features compared to macroreactors due to their smaller volumes and reduced chemical inventories, minimizing the potential impact of accidents. Their high surface-area-to-volume ratio allows for superior heat dissipation, lowering the risk of thermal runaway and hazardous conditions. Advanced sensors and automated controls in microreactors enable real-time monitoring and rapid response, further mitigating operational risks.

Economic and Sustainability Analysis

Microreactors offer significant economic advantages due to lower capital investment, reduced energy consumption, and minimized raw material waste compared to traditional macroreactors. Sustainability analysis highlights microreactors' enhanced process intensification, enabling faster reaction times and higher yields with less environmental impact. Macroreactors, while benefiting from economies of scale, often face challenges in energy efficiency and waste management, making microreactors a more viable option for green chemical manufacturing.

Industrial Applications and Case Studies

Microreactors offer enhanced heat and mass transfer rates, enabling precise control and rapid scale-up in pharmaceutical and chemical industries, improving catalyst efficiency and reducing waste. Macroreactors remain ideal for high-volume production such as petrochemical refining, with case studies demonstrating their robustness in large-scale hydrogenation and polymerization processes. Industrial applications reveal microreactors excel in continuous flow synthesis for specialty chemicals, while macroreactors dominate bulk manufacturing due to their higher throughput capacity.

Future Trends and Research Directions

Microreactors offer enhanced heat and mass transfer rates, enabling precise control over reaction conditions and improved scalability for pharmaceutical synthesis, while macroreactors remain dominant for large-scale industrial applications due to their established infrastructure. Future trends emphasize integrating microreactor technology with continuous flow processes and advanced automation to increase efficiency, reduce waste, and enable real-time reaction monitoring through embedded sensors. Research directions focus on developing novel materials for reactor fabrication, optimizing catalyst placement, and expanding applications in green chemistry and fine chemical production.

Residence Time Distribution

Microreactors exhibit narrow and uniform residence time distribution (RTD) due to their small channel dimensions, enhancing reaction control and selectivity compared to macroreactors, which typically have broader RTD leading to increased back-mixing and reduced process efficiency.

Heat and Mass Transfer Efficiency

Microreactors achieve superior heat and mass transfer efficiency compared to macroreactors due to their high surface-to-volume ratio and enhanced mixing capabilities.

Surface-to-Volume Ratio

Microreactors exhibit a significantly higher surface-to-volume ratio than macroreactors, enhancing heat and mass transfer efficiencies crucial for precise chemical reactions.

Flow Regimes (Laminar vs Turbulent)

Microreactors primarily operate under laminar flow regimes due to their small dimensions, enhancing precise control and mixing efficiency, while macroreactors often experience turbulent flow that promotes bulk mixing but can reduce reaction selectivity.

Process Intensification

Microreactors enhance process intensification by offering superior heat and mass transfer rates, precise reaction control, and reduced volume, compared to traditional macroreactors.

Scale-Up Challenges

Microreactors face scale-up challenges due to limited throughput and heat transfer issues, whereas macroreactors encounter difficulties in maintaining uniform mixing and temperature control at large volumes.

Mixing Efficiency

Microreactors achieve superior mixing efficiency through enhanced surface-to-volume ratios and laminar flow conditions compared to macroreactors, resulting in faster mass transfer and improved reaction control.

Pressure Drop

Microreactors exhibit significantly lower pressure drops compared to macroreactors due to their enhanced surface-to-volume ratio and optimized flow channels, enabling more efficient fluid dynamics in high-pressure applications.

Reaction Kinetics Control

Microreactors offer superior reaction kinetics control through enhanced surface-to-volume ratios and precise temperature management compared to macroreactors.

Parallelization (Numbering Up)

Parallelization in microreactors, achieved through numbering up multiple small units, enhances process scalability and control more efficiently than scaling macroreactors.

Microreactors vs Macroreactors Infographic

njnir.com

njnir.com