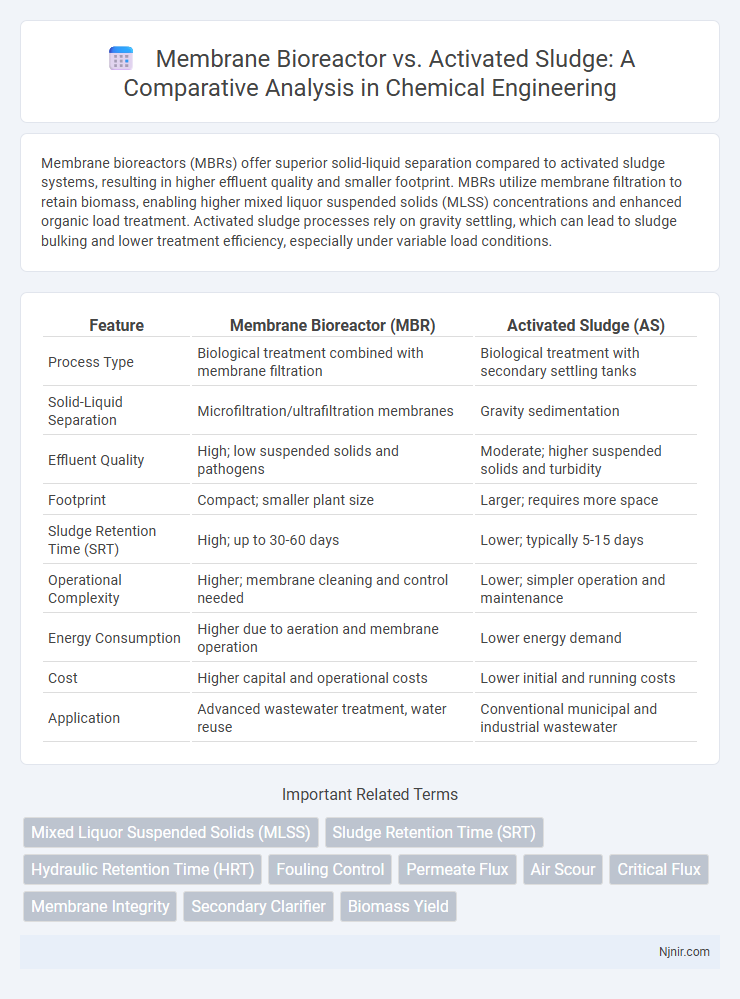

Membrane bioreactors (MBRs) offer superior solid-liquid separation compared to activated sludge systems, resulting in higher effluent quality and smaller footprint. MBRs utilize membrane filtration to retain biomass, enabling higher mixed liquor suspended solids (MLSS) concentrations and enhanced organic load treatment. Activated sludge processes rely on gravity settling, which can lead to sludge bulking and lower treatment efficiency, especially under variable load conditions.

Table of Comparison

| Feature | Membrane Bioreactor (MBR) | Activated Sludge (AS) |

|---|---|---|

| Process Type | Biological treatment combined with membrane filtration | Biological treatment with secondary settling tanks |

| Solid-Liquid Separation | Microfiltration/ultrafiltration membranes | Gravity sedimentation |

| Effluent Quality | High; low suspended solids and pathogens | Moderate; higher suspended solids and turbidity |

| Footprint | Compact; smaller plant size | Larger; requires more space |

| Sludge Retention Time (SRT) | High; up to 30-60 days | Lower; typically 5-15 days |

| Operational Complexity | Higher; membrane cleaning and control needed | Lower; simpler operation and maintenance |

| Energy Consumption | Higher due to aeration and membrane operation | Lower energy demand |

| Cost | Higher capital and operational costs | Lower initial and running costs |

| Application | Advanced wastewater treatment, water reuse | Conventional municipal and industrial wastewater |

Introduction to Membrane Bioreactors and Activated Sludge Systems

Membrane bioreactors (MBRs) combine conventional activated sludge treatment with membrane filtration, enhancing solids separation and effluent quality by integrating microfiltration or ultrafiltration membranes. Activated sludge systems rely on aerated biological processes to degrade organic pollutants and settle suspended solids through sedimentation, producing treated wastewater and biomass. MBRs offer higher biomass concentrations and smaller footprints compared to traditional activated sludge, making them suitable for advanced wastewater treatment and water reuse applications.

Process Fundamentals of MBR and Activated Sludge

Membrane bioreactors (MBRs) combine conventional activated sludge processes with membrane filtration, enhancing solids-liquid separation and allowing higher mixed liquor suspended solids (MLSS) concentrations typically ranging from 8,000 to 15,000 mg/L. Activated sludge systems rely on aeration and microbial degradation of organic matter with MLSS concentrations generally between 2,000 and 4,000 mg/L, followed by gravity settling for solids separation. MBRs use microfiltration or ultrafiltration membranes to retain biomass and achieve superior effluent quality, while activated sludge depends on settling tanks, often leading to lower solid retention times and potential sludge bulking issues.

Key Differences in System Configuration

Membrane bioreactors (MBRs) combine a suspended growth biological treatment process with membrane filtration, replacing conventional secondary clarifiers used in activated sludge systems. Activated sludge systems rely on gravity settling for biomass separation, whereas MBRs utilize micro or ultrafiltration membranes for solid-liquid separation, enabling higher mixed liquor suspended solids (MLSS) concentrations. This compact membrane integration in MBRs results in smaller footprint designs and enhanced effluent quality compared to traditional activated sludge configurations.

Microbial Community Dynamics Comparison

Membrane bioreactors (MBRs) maintain a more stable and diverse microbial community than conventional activated sludge systems, enhancing biodegradation efficiency and system resilience. The physical separation by membranes in MBRs reduces biomass washout, promoting the growth of slow-growing, specialized microbes critical for nutrient removal. In contrast, activated sludge systems often exhibit greater microbial fluctuations due to higher sludge wastage and less effective solids retention, impacting treatment consistency.

Performance in Organic and Nutrient Removal

Membrane bioreactors (MBRs) demonstrate superior performance in organic and nutrient removal compared to conventional activated sludge systems due to their enhanced biomass retention and higher mixed liquor suspended solids (MLSS) concentrations. MBRs achieve greater removal efficiencies of biochemical oxygen demand (BOD), total nitrogen (TN), and total phosphorus (TP) by integrating membrane filtration with biological treatment, facilitating longer sludge retention times and finer biomass separation. This results in improved effluent quality with lower concentrations of organic compounds and nutrients, making MBRs more effective for stringent wastewater treatment standards.

Operational Costs and Energy Efficiency

Membrane bioreactors (MBRs) typically incur higher operational costs than conventional activated sludge systems due to membrane maintenance and replacement expenses. Despite this, MBRs offer greater energy efficiency by enabling higher mixed liquor suspended solids (MLSS) concentrations, which reduce aeration demands. Activated sludge systems generally consume more energy for aeration but have lower upfront and maintenance costs compared to MBR technology.

Effluent Quality and Reuse Potential

Membrane bioreactors (MBRs) provide superior effluent quality compared to activated sludge systems, achieving lower levels of biochemical oxygen demand (BOD), total suspended solids (TSS), and pathogens due to their high-resolution membrane filtration. MBR effluent exhibits enhanced reuse potential for applications such as irrigation and industrial processes, meeting stringent discharge standards with reduced post-treatment requirements. Activated sludge effluent typically requires additional tertiary treatment to achieve similar water quality, limiting its direct reuse capabilities.

Sludge Production and Handling

Membrane bioreactors (MBRs) generate significantly less sludge compared to conventional activated sludge systems due to higher biomass retention and more complete organic matter degradation. The reduced sludge volume in MBRs minimizes handling and disposal costs while improving overall process efficiency. Activated sludge systems produce higher quantities of excess sludge, requiring more frequent handling and increased disposal efforts, impacting operational costs and environmental management.

Scalability and Applicability in Industry

Membrane bioreactor (MBR) systems offer superior scalability compared to activated sludge processes, enabling efficient handling of varying industrial wastewater volumes without compromising treatment quality. MBR technology is highly applicable in industries with stringent effluent standards, such as pharmaceuticals and food processing, due to its advanced solid-liquid separation and compact footprint. Activated sludge remains prevalent in large-scale municipal applications but faces limitations in adaptability and footprint reduction for industries requiring high-quality effluent at smaller scales.

Future Trends and Technological Innovations

Membrane bioreactor (MBR) technology is evolving with innovations such as advanced membranes that enhance filtration efficiency and reduce fouling, driving its adoption in wastewater treatment over traditional activated sludge systems. Future trends indicate increased integration of MBR with AI-driven monitoring and automation to optimize operational performance and energy consumption. Activated sludge processes continue to improve through hybrid systems combining biological treatment with MBR elements, targeting higher treatment capacity and compliance with stricter environmental regulations.

Mixed Liquor Suspended Solids (MLSS)

Membrane bioreactors (MBRs) typically operate at higher Mixed Liquor Suspended Solids (MLSS) concentrations of 8,000-12,000 mg/L compared to activated sludge systems, which usually maintain MLSS levels around 2,000-4,000 mg/L, resulting in improved biomass retention and treatment efficiency in MBRs.

Sludge Retention Time (SRT)

Membrane bioreactors (MBRs) achieve longer Sludge Retention Times (SRTs) than activated sludge systems by retaining biomass with membrane filtration, enhancing treatment efficiency and biomass concentration.

Hydraulic Retention Time (HRT)

Membrane bioreactors typically have shorter Hydraulic Retention Times (HRT) of 4-8 hours compared to activated sludge systems, which often require 6-12 hours for effective treatment and sludge separation.

Fouling Control

Membrane bioreactors offer superior fouling control compared to activated sludge systems by utilizing fine pore membranes and optimized aeration techniques to minimize biofilm buildup and enhance filtration efficiency.

Permeate Flux

Membrane bioreactors achieve higher permeate flux rates than activated sludge systems due to enhanced solid-liquid separation and reduced fouling.

Air Scour

Membrane bioreactors use air scour to effectively clean membranes and enhance filtration efficiency, whereas activated sludge systems rely on aeration primarily for microbial oxygen supply and mixing.

Critical Flux

Membrane bioreactors maintain higher critical flux rates than activated sludge systems, enabling improved filtration efficiency and reduced membrane fouling in wastewater treatment.

Membrane Integrity

Membrane bioreactors maintain superior membrane integrity compared to activated sludge systems by preventing membrane fouling and enabling consistent filtration performance in wastewater treatment.

Secondary Clarifier

Membrane bioreactors eliminate the need for a secondary clarifier by integrating membrane filtration for biomass separation, whereas activated sludge systems rely on secondary clarifiers for settling and separating treated wastewater.

Biomass Yield

Membrane bioreactors achieve lower biomass yield compared to activated sludge systems due to enhanced biomass retention and higher microbial growth efficiency.

Membrane bioreactor vs Activated sludge Infographic

njnir.com

njnir.com