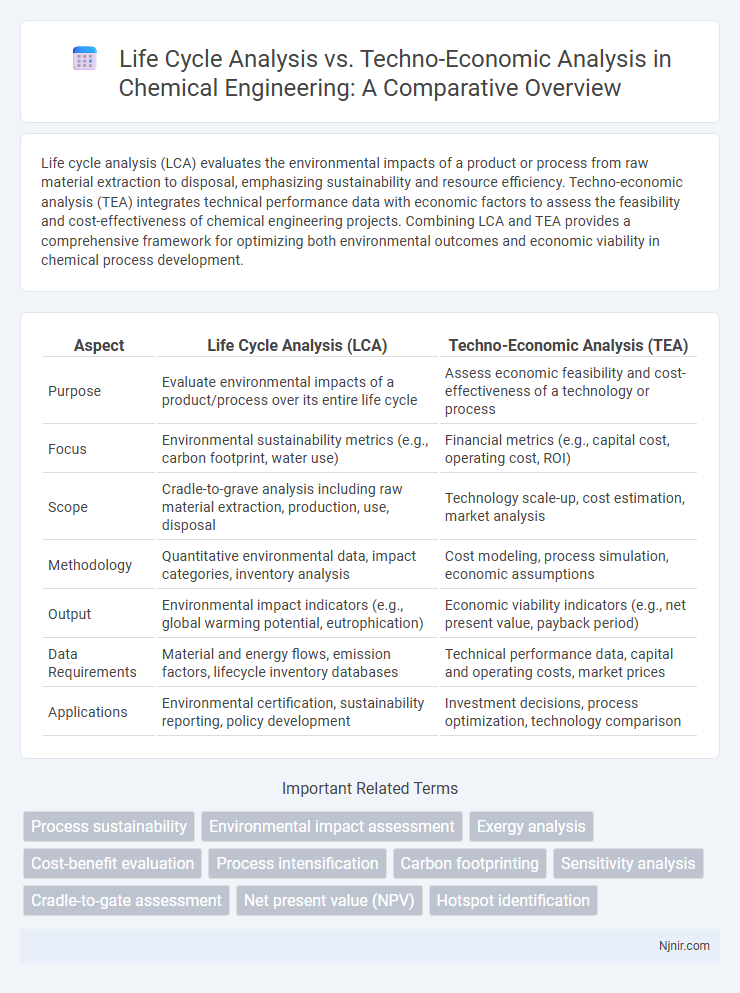

Life cycle analysis (LCA) evaluates the environmental impacts of a product or process from raw material extraction to disposal, emphasizing sustainability and resource efficiency. Techno-economic analysis (TEA) integrates technical performance data with economic factors to assess the feasibility and cost-effectiveness of chemical engineering projects. Combining LCA and TEA provides a comprehensive framework for optimizing both environmental outcomes and economic viability in chemical process development.

Table of Comparison

| Aspect | Life Cycle Analysis (LCA) | Techno-Economic Analysis (TEA) |

|---|---|---|

| Purpose | Evaluate environmental impacts of a product/process over its entire life cycle | Assess economic feasibility and cost-effectiveness of a technology or process |

| Focus | Environmental sustainability metrics (e.g., carbon footprint, water use) | Financial metrics (e.g., capital cost, operating cost, ROI) |

| Scope | Cradle-to-grave analysis including raw material extraction, production, use, disposal | Technology scale-up, cost estimation, market analysis |

| Methodology | Quantitative environmental data, impact categories, inventory analysis | Cost modeling, process simulation, economic assumptions |

| Output | Environmental impact indicators (e.g., global warming potential, eutrophication) | Economic viability indicators (e.g., net present value, payback period) |

| Data Requirements | Material and energy flows, emission factors, lifecycle inventory databases | Technical performance data, capital and operating costs, market prices |

| Applications | Environmental certification, sustainability reporting, policy development | Investment decisions, process optimization, technology comparison |

Introduction to Life Cycle Analysis and Techno-Economic Analysis

Life Cycle Analysis (LCA) systematically assesses the environmental impacts of a product or process throughout its entire lifespan, from raw material extraction to disposal. Techno-Economic Analysis (TEA) evaluates the economic feasibility and performance metrics of technologies, integrating cost estimation with technical parameters. Both methodologies provide crucial insights for sustainable decision-making by balancing environmental consequences and economic viability in innovation and development projects.

Defining Life Cycle Analysis in Chemical Engineering

Life Cycle Analysis (LCA) in chemical engineering evaluates the environmental impacts of a product or process from raw material extraction to disposal, emphasizing sustainability and resource efficiency. It quantifies factors such as energy consumption, emissions, and waste generation throughout the entire life cycle. Compared to Techno-Economic Analysis (TEA), which focuses on cost, economic feasibility, and financial performance, LCA prioritizes ecological footprint and environmental trade-offs in process development.

Fundamentals of Techno-Economic Analysis

Techno-economic analysis (TEA) fundamentally integrates technical performance data with economic metrics to evaluate the feasibility and cost-effectiveness of technologies or processes. Unlike life cycle analysis (LCA), which focuses on environmental impacts throughout a product's life span, TEA emphasizes capital expenditures, operational costs, and market factors to determine profitability and investment viability. Key components of TEA include process modeling, cost estimation, sensitivity analysis, and economic indicators such as net present value (NPV) and internal rate of return (IRR).

Key Differences Between Life Cycle Analysis and Techno-Economic Analysis

Life Cycle Analysis (LCA) assesses environmental impacts of a product or process throughout its entire life span, including raw material extraction, manufacturing, use, and disposal, while Techno-Economic Analysis (TEA) evaluates the economic feasibility and performance metrics of technologies or projects, focusing on costs, revenue, and financial viability. LCA emphasizes sustainability metrics such as carbon footprint, energy consumption, and waste generation, whereas TEA centers on capital expenditure (CAPEX), operational expenditure (OPEX), and return on investment (ROI). The key difference lies in LCA's comprehensive environmental impact scope versus TEA's focus on economic cost-benefit assessment for technology deployment.

Purpose and Applications in Chemical Process Design

Life cycle analysis (LCA) evaluates the environmental impacts of chemical processes from raw material extraction to disposal, supporting sustainable design decisions and regulatory compliance. Techno-economic analysis (TEA) quantifies economic feasibility by assessing capital costs, operating expenses, and market factors, guiding investment and commercialization strategies. Combining LCA and TEA enables integrated assessment of environmental performance and economic viability, optimizing chemical process design for sustainability and profitability.

Comparative Methodologies: LCA vs TEA

Life Cycle Analysis (LCA) evaluates environmental impacts across a product's entire life span, emphasizing sustainability metrics like carbon footprint, energy consumption, and resource depletion. Techno-Economic Analysis (TEA) focuses on financial performance and economic feasibility, analyzing cost factors such as capital expenses, operational costs, and return on investment. Comparing LCA and TEA reveals complementary methodologies where LCA addresses ecological sustainability while TEA assesses economic viability, essential for comprehensive decision-making in technology development and project implementation.

Core Metrics and Assessment Parameters

Life cycle analysis (LCA) evaluates environmental impacts across a product's entire lifespan using core metrics such as carbon footprint, energy consumption, and water usage, emphasizing sustainability and ecological burden. Techno-economic analysis (TEA) focuses on financial viability by assessing parameters like capital expenditure, operating costs, internal rate of return (IRR), and payback period. Both methodologies incorporate sensitivity and uncertainty analysis but diverge in prioritizing environmental impact versus economic feasibility metrics.

Integrating LCA and TEA for Sustainable Process Development

Integrating Life Cycle Analysis (LCA) and Techno-Economic Analysis (TEA) provides a comprehensive framework for sustainable process development by evaluating environmental impacts alongside economic feasibility. This combined approach enables identification of trade-offs between ecological footprint and cost-efficiency, optimizing resource use and reducing emissions throughout the entire product life cycle. Utilizing integrated LCA-TEA models supports decision-making in process design by balancing sustainability goals with market constraints and profitability metrics.

Challenges in Implementing LCA and TEA

Challenges in implementing Life Cycle Analysis (LCA) include data availability, quality inconsistencies, and system boundary definitions, which complicate accurate environmental impact assessments across product lifecycles. Techno-economic Analysis (TEA) faces challenges in forecasting technology costs, market dynamics, and integrating uncertain economic parameters, often resulting in variable financial feasibility outcomes. Both methods require extensive interdisciplinary collaboration and standardized methodologies to improve reliability and decision-making effectiveness in sustainability evaluations.

Future Trends in Life Cycle and Techno-Economic Evaluations

Future trends in life cycle analysis (LCA) and techno-economic analysis (TEA) emphasize integrating artificial intelligence and big data to enhance predictive accuracy and real-time decision-making. Advanced hybrid models combining environmental impact assessments with cost-benefit evaluations are becoming standard for sustainable technology development, particularly in renewable energy and circular economy sectors. Increased focus on digital twins and blockchain technology improves transparency and traceability in LCA and TEA, facilitating more robust sustainability metrics and stakeholder trust.

Process sustainability

Life cycle analysis evaluates environmental impacts across all process stages to ensure sustainability, while techno-economic analysis assesses cost-effectiveness and economic viability, both crucial for optimizing sustainable process development.

Environmental impact assessment

Life cycle analysis provides a comprehensive environmental impact assessment by evaluating the entire product lifecycle, while techno-economic analysis primarily focuses on cost efficiency and feasibility, often overlooking detailed environmental impacts.

Exergy analysis

Exergy analysis enhances life cycle analysis by quantifying energy quality and efficiency, while techno-economic analysis evaluates cost-effectiveness, making exergy a critical metric for optimizing sustainable energy systems.

Cost-benefit evaluation

Life cycle analysis evaluates environmental impacts throughout a product's lifespan while techno-economic analysis focuses on quantifying costs and economic benefits for informed cost-benefit evaluation.

Process intensification

Process intensification enhances both life cycle analysis and techno-economic analysis by minimizing environmental impacts and reducing capital and operational costs through streamlined process designs.

Carbon footprinting

Life cycle analysis provides comprehensive carbon footprinting by assessing environmental impacts across all product stages, while techno-economic analysis evaluates the cost-effectiveness of carbon reduction technologies without fully capturing their lifecycle emissions.

Sensitivity analysis

Sensitivity analysis in life cycle analysis evaluates environmental impact variability, while in techno-economic analysis it assesses cost-effectiveness under uncertain economic parameters.

Cradle-to-gate assessment

Cradle-to-gate life cycle analysis evaluates environmental impacts from raw material extraction to factory gate, while techno-economic analysis assesses the cost-effectiveness and economic feasibility of the production process within the same boundary.

Net present value (NPV)

Life cycle analysis assesses environmental impacts throughout a product's lifespan, while techno-economic analysis evaluates financial viability using metrics like Net Present Value (NPV) to measure investment profitability.

Hotspot identification

Life cycle analysis identifies environmental hotspots by evaluating the full product life cycle, while techno-economic analysis pinpoints cost-intensive hotspots by assessing economic feasibility and technology performance.

Life cycle analysis vs Techno-economic analysis Infographic

njnir.com

njnir.com