Ultrasonic mixing enhances chemical reactions by generating cavitation bubbles that improve mass transfer rates and dispersion uniformity, offering superior efficiency compared to mechanical stirring. Mechanical stirring relies on physical agitation, which can be less effective in achieving homogenous mixtures for high-viscosity fluids or nanoscale particle suspensions. Ultrasonic mixing provides precise control over mixing intensity and reduces processing time, making it ideal for advanced chemical engineering applications.

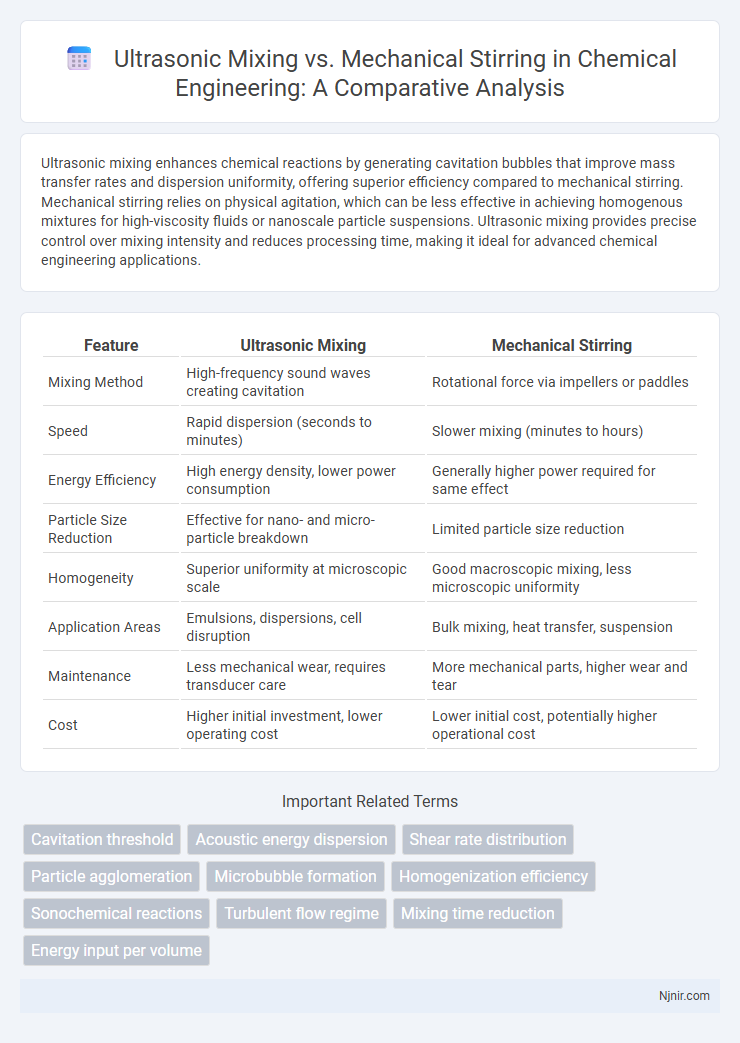

Table of Comparison

| Feature | Ultrasonic Mixing | Mechanical Stirring |

|---|---|---|

| Mixing Method | High-frequency sound waves creating cavitation | Rotational force via impellers or paddles |

| Speed | Rapid dispersion (seconds to minutes) | Slower mixing (minutes to hours) |

| Energy Efficiency | High energy density, lower power consumption | Generally higher power required for same effect |

| Particle Size Reduction | Effective for nano- and micro-particle breakdown | Limited particle size reduction |

| Homogeneity | Superior uniformity at microscopic scale | Good macroscopic mixing, less microscopic uniformity |

| Application Areas | Emulsions, dispersions, cell disruption | Bulk mixing, heat transfer, suspension |

| Maintenance | Less mechanical wear, requires transducer care | More mechanical parts, higher wear and tear |

| Cost | Higher initial investment, lower operating cost | Lower initial cost, potentially higher operational cost |

Introduction to Mixing Techniques in Chemical Engineering

Ultrasonic mixing utilizes high-frequency sound waves to generate cavitation bubbles, promoting intense micro-mixing and enhancing mass transfer efficiency in chemical processes. Mechanical stirring relies on rotating impellers to create bulk fluid motion, providing macroscopic mixing through shear forces and turbulence. Selecting between ultrasonic and mechanical mixing depends on factors such as scale, viscosity, reaction kinetics, and the required mixing uniformity in chemical engineering applications.

Fundamentals of Ultrasonic Mixing

Ultrasonic mixing utilizes high-frequency sound waves to create cavitation bubbles in liquids, which collapse and generate intense local shear forces, leading to rapid and uniform mixing at the microscopic level. Mechanical stirring relies on impellers or blades to physically agitate fluids, producing macroscopic turbulence that is less efficient for blending viscous or heterogeneous mixtures. The fundamental advantage of ultrasonic mixing lies in its ability to enhance mass transfer and dispersion without excessive heat generation or mechanical wear.

Principles of Mechanical Stirring

Mechanical stirring operates on the principle of physically agitating a liquid using a rotating impeller or blade to create turbulence and enhance mixing. The impeller's design and speed generate shear forces that distribute particles or solutes uniformly throughout the fluid. This method relies on direct contact and mechanical energy transfer to achieve homogenous mixtures in various industrial and laboratory applications.

Energy Consumption Comparison

Ultrasonic mixing consumes significantly less energy compared to mechanical stirring due to its efficient high-frequency vibration mechanism, which promotes rapid and uniform dispersion with minimal power input. Mechanical stirring relies on continuous rotational movement that often requires higher torque and longer operational time, leading to increased electricity usage. Studies reveal that ultrasonic mixers can reduce energy consumption by up to 50% while maintaining or improving mixing quality in industrial processes.

Mixing Efficiency and Homogeneity

Ultrasonic mixing delivers superior mixing efficiency and homogeneity compared to mechanical stirring by generating high-frequency cavitation that promotes rapid dispersion and particle size reduction. Mechanical stirring often results in uneven distribution and longer processing times, especially in viscous or complex fluids, due to limited shear forces and turbulent flow. Ultrasonic mixing enables uniform particle distribution at the microscale, enhancing product consistency and reaction rates in applications such as emulsification, nanoparticle synthesis, and chemical processing.

Impact on Particle Size and Dispersion

Ultrasonic mixing significantly reduces particle size through high-frequency cavitation, leading to enhanced dispersion and uniformity in suspensions compared to mechanical stirring. Mechanical stirring often results in larger, less uniform particles due to limited shear forces and mixing efficiency. Ultrasonic methods improve stability and homogeneity in colloidal systems by breaking agglomerates and preventing reaggregation more effectively than traditional mechanical techniques.

Scalability and Industrial Applications

Ultrasonic mixing offers superior scalability with precise control over cavitation intensity and frequency, enabling consistent results from laboratory to industrial scale in industries such as pharmaceuticals, food, and chemical processing. Mechanical stirring remains widely used in large-scale operations due to its simplicity and lower initial cost, but it may struggle with achieving homogeneity in highly viscous or complex mixtures that ultrasonic mixing can handle efficiently. Industrial applications benefit from ultrasonic mixing's enhanced dispersion, emulsification, and particle size reduction, which are critical for product quality and process efficiency in sectors requiring fine control and reproducibility.

Effect on Reaction Kinetics

Ultrasonic mixing improves reaction kinetics by generating cavitation bubbles that enhance mass transfer and increase the surface area for chemical interactions, leading to faster reaction rates. Mechanical stirring relies on macroscopic fluid motion to promote mixing, often resulting in slower reaction kinetics due to less efficient micro-scale mixing. Ultrasound's ability to induce localized high-energy conditions accelerates reactions that are diffusion-limited or require intense mixing at the molecular level.

Maintenance and Operational Challenges

Ultrasonic mixing requires regular inspection and cleaning of transducers to prevent fouling and ensure consistent energy delivery, which can pose maintenance challenges compared to mechanical stirring systems. Mechanical stirrers often involve wear and tear of moving parts such as bearings and seals, necessitating frequent lubrication and part replacement to maintain operational stability. Both methods demand careful monitoring; however, ultrasonic systems typically have higher initial maintenance costs but provide more precise control with fewer mechanical failures over time.

Cost Analysis and Economic Considerations

Ultrasonic mixing offers energy-efficient processing with reduced operational time compared to mechanical stirring, leading to lower long-term energy costs despite higher initial equipment investment. Mechanical stirring typically incurs lower upfront equipment expenses but results in increased maintenance and energy consumption over extended use, impacting overall cost-effectiveness. Economic considerations must weigh the trade-off between ultrasonic technology's rapid processing benefits and its capital expenditure against the more affordable but less efficient mechanical stirring methods.

Cavitation threshold

Ultrasonic mixing surpasses mechanical stirring by achieving cavitation thresholds at lower energy inputs, enhancing dispersion and reaction rates in liquid media.

Acoustic energy dispersion

Ultrasonic mixing disperses acoustic energy more uniformly and intensely throughout the medium compared to mechanical stirring, resulting in enhanced homogeneity and faster reaction rates.

Shear rate distribution

Ultrasonic mixing generates a more uniform and higher shear rate distribution compared to mechanical stirring, enhancing particle dispersion and reaction kinetics in fluid systems.

Particle agglomeration

Ultrasonic mixing effectively reduces particle agglomeration by generating high-frequency cavitation and shear forces, whereas mechanical stirring often results in incomplete dispersion and larger agglomerates.

Microbubble formation

Ultrasonic mixing generates smaller and more uniformly distributed microbubbles than mechanical stirring, enhancing mass transfer and reaction rates in liquid mediums.

Homogenization efficiency

Ultrasonic mixing achieves significantly higher homogenization efficiency than mechanical stirring by generating intense cavitation and microturbulence, leading to uniform particle dispersion and faster mixing times.

Sonochemical reactions

Ultrasonic mixing enhances sonochemical reactions by generating cavitation bubbles that produce localized high temperatures and pressures, resulting in more efficient chemical transformations compared to conventional mechanical stirring.

Turbulent flow regime

Ultrasonic mixing generates a more intense turbulent flow regime with higher shear forces and improved micromixing efficiency compared to mechanical stirring in various industrial applications.

Mixing time reduction

Ultrasonic mixing reduces mixing time by up to 70% compared to mechanical stirring due to its intense cavitation and microstreaming effects.

Energy input per volume

Ultrasonic mixing delivers significantly higher energy input per volume compared to mechanical stirring, enhancing dispersion efficiency and reaction rates in various applications.

ultrasonic mixing vs mechanical stirring Infographic

njnir.com

njnir.com