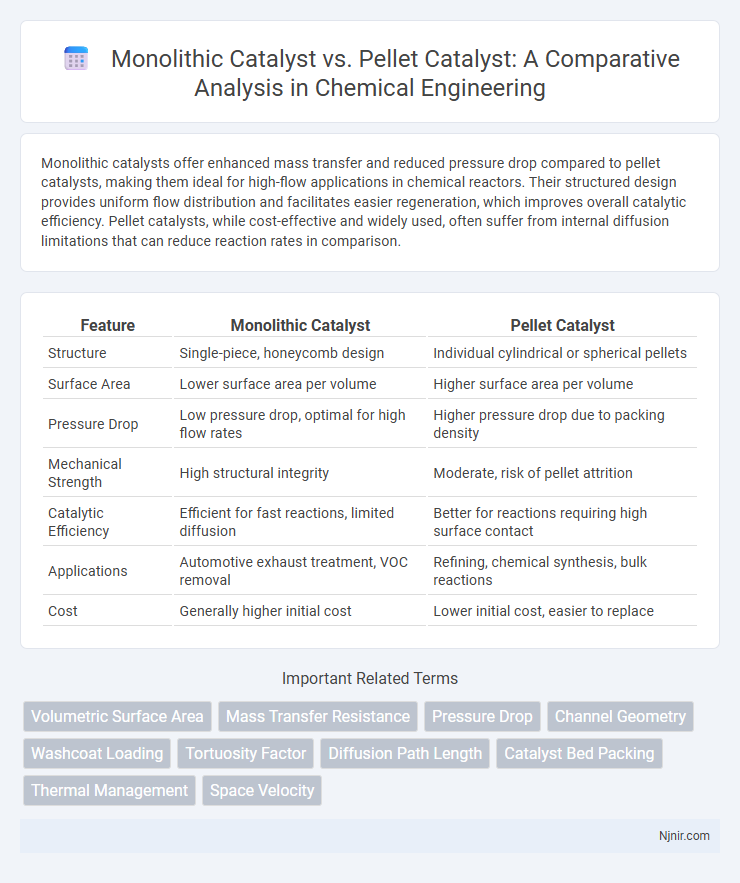

Monolithic catalysts offer enhanced mass transfer and reduced pressure drop compared to pellet catalysts, making them ideal for high-flow applications in chemical reactors. Their structured design provides uniform flow distribution and facilitates easier regeneration, which improves overall catalytic efficiency. Pellet catalysts, while cost-effective and widely used, often suffer from internal diffusion limitations that can reduce reaction rates in comparison.

Table of Comparison

| Feature | Monolithic Catalyst | Pellet Catalyst |

|---|---|---|

| Structure | Single-piece, honeycomb design | Individual cylindrical or spherical pellets |

| Surface Area | Lower surface area per volume | Higher surface area per volume |

| Pressure Drop | Low pressure drop, optimal for high flow rates | Higher pressure drop due to packing density |

| Mechanical Strength | High structural integrity | Moderate, risk of pellet attrition |

| Catalytic Efficiency | Efficient for fast reactions, limited diffusion | Better for reactions requiring high surface contact |

| Applications | Automotive exhaust treatment, VOC removal | Refining, chemical synthesis, bulk reactions |

| Cost | Generally higher initial cost | Lower initial cost, easier to replace |

Introduction to Catalysts in Chemical Engineering

Catalysts in chemical engineering accelerate reaction rates without being consumed, with monolithic and pellet catalysts serving distinct roles. Monolithic catalysts feature a structured, honeycomb design that offers low pressure drop and high mass transfer efficiency, often used in automotive and environmental applications. Pellet catalysts, composed of granular particles, provide high surface area and are commonly employed in fixed-bed reactors for processes such as hydrocracking and catalytic reforming.

Overview of Monolithic and Pellet Catalysts

Monolithic catalysts consist of a single, continuous structure with parallel channels coated by a catalytic material, enabling low pressure drop and high mass transfer rates, ideal for automotive exhaust treatment and industrial gas processing. Pellet catalysts are made of small, individual particles or extrudates of catalytic material, providing high surface area and flexibility in packing density, commonly used in fixed-bed reactors for petrochemical and environmental applications. The choice between monolithic and pellet catalysts depends on reactor design, reaction kinetics, and operational conditions, balancing factors like flow dynamics and catalyst accessibility.

Structural Differences: Monolithic vs Pellet Catalysts

Monolithic catalysts feature a continuous, honeycomb-like structure composed of parallel channels, providing low-pressure drop and high surface area for catalytic reactions. Pellet catalysts consist of discrete, porous granules or pellets that offer greater surface accessibility but result in higher pressure drops compared to monolithic designs. The distinct structural differences impact mass transfer efficiency, catalyst loading, and operational stability in various chemical processing applications.

Material Composition and Manufacturing Methods

Monolithic catalysts are primarily composed of ceramic or metal substrates with a honeycomb structure, allowing high surface area and low pressure drop, manufactured through extrusion or fiber-ceramic techniques. Pellet catalysts consist of granular materials such as alumina, silica, or zeolites, formed by pelletizing, extrusion, or spherical granulation processes to maximize active site exposure. Differences in material composition directly influence their mechanical strength, thermal conductivity, and catalytic efficiency, while manufacturing methods determine the porosity and diffusion characteristics essential for specific applications.

Performance Efficiency in Industrial Applications

Monolithic catalysts offer higher surface area-to-volume ratios and lower pressure drops, enhancing mass transfer and reaction rates in industrial applications compared to pellet catalysts. Pellet catalysts, while providing greater mechanical strength and ease of replacement, often suffer from diffusion limitations that reduce overall catalytic efficiency. The choice between monolithic and pellet catalysts depends on specific process requirements such as flow dynamics, reaction kinetics, and operational costs.

Mass and Heat Transfer Characteristics

Monolithic catalysts exhibit superior mass transfer properties due to their structured channels, reducing pressure drop and enhancing reactant diffusion compared to pellet catalysts, which have porous but often tortuous pathways causing higher resistance. Heat transfer in monolithic catalysts is more efficient because their thin walls and high thermal conductivity ensure rapid temperature equalization, while pellet catalysts tend to retain heat unevenly due to internal pore structures and lower thermal conductivity. Optimizing mass and heat transfer in monolithic catalysts leads to improved catalytic performance and energy efficiency in industrial applications.

Pressure Drop and Fluid Dynamics

Monolithic catalysts exhibit significantly lower pressure drop compared to pellet catalysts due to their structured channels, facilitating smoother fluid flow and enhanced mass transfer. Pellet catalysts create higher pressure drops as fluid passes through randomly packed particles, causing turbulence and increased flow resistance. Optimizing fluid dynamics in monolithic catalysts improves reaction efficiency and reduces energy consumption in industrial processes.

Longevity, Maintenance, and Regeneration

Monolithic catalysts offer superior longevity due to their robust structure that resists thermal and mechanical degradation, reducing the frequency of replacement compared to pellet catalysts. Maintenance is typically lower for monolithic catalysts, as their continuous channels minimize pressure drop and fouling, whereas pellet catalysts often require more frequent cleaning to prevent clogging and attrition. Regeneration processes for monolithic catalysts are generally more efficient and less labor-intensive, resulting in reduced downtime, while pellet catalysts may demand more complex handling to restore activity after deactivation.

Economic Considerations and Cost Analysis

Monolithic catalysts offer lower pressure drop and higher mass transfer efficiency, resulting in reduced energy consumption and operational costs compared to pellet catalysts. Pellet catalysts typically require higher catalyst volume and generate increased pressure drop, leading to greater capital expenditures for reactor design and maintenance. Economic considerations favor monolithic catalysts due to their longer lifespan and reduced catalyst replacement frequency, which together minimize total cost of ownership in industrial catalytic processes.

Application Suitability: Choosing the Right Catalyst

Monolithic catalysts excel in high-flow applications such as automotive exhaust treatment due to their low pressure drop and uniform flow distribution. Pellet catalysts are preferred in chemical processes requiring high surface area and flexibility in reactor design, such as hydroprocessing and gas-phase reactions. Selecting the right catalyst depends on process conditions, including flow rates, temperature, and space constraints to optimize performance and efficiency.

Volumetric Surface Area

Monolithic catalysts typically offer lower volumetric surface area compared to pellet catalysts due to their structured geometry, impacting catalytic efficiency in volume-constrained applications.

Mass Transfer Resistance

Monolithic catalysts exhibit lower mass transfer resistance compared to pellet catalysts due to their structured channels that enhance reactant diffusion and minimize pressure drop.

Pressure Drop

Monolithic catalysts typically exhibit significantly lower pressure drop compared to pellet catalysts due to their structured channels that facilitate smoother gas flow.

Channel Geometry

Monolithic catalyst features continuous channels with high geometric surface area optimizing flow distribution, whereas pellet catalyst consists of discrete porous particles with irregular channel spaces affecting mass transfer efficiency.

Washcoat Loading

Monolithic catalysts typically offer lower washcoat loading compared to pellet catalysts, enabling enhanced mass transfer and reduced pressure drop in catalytic converters.

Tortuosity Factor

The tortuosity factor in monolithic catalysts is generally lower than in pellet catalysts, enhancing mass transfer rates and improving overall catalytic efficiency.

Diffusion Path Length

Monolithic catalysts offer a significantly shorter diffusion path length than pellet catalysts, enhancing mass transfer efficiency and catalytic reaction rates.

Catalyst Bed Packing

Monolithic catalyst beds offer lower pressure drop and higher flow distribution efficiency compared to pellet catalyst beds, which typically provide higher surface area but suffer from channeling and uneven packing density.

Thermal Management

Monolithic catalysts offer superior thermal management compared to pellet catalysts due to their uniform structure and higher thermal conductivity, enabling efficient heat distribution and reduced hotspot formation in catalytic reactors.

Space Velocity

Monolithic catalysts typically achieve higher space velocity than pellet catalysts due to their structured channels enabling enhanced mass transfer and lower pressure drop in catalytic reactors.

Monolithic Catalyst vs Pellet Catalyst Infographic

njnir.com

njnir.com