Heat exchangers transfer thermal energy between two or more fluids without mixing them, optimizing energy efficiency in chemical processes. Heat pumps move heat from a lower temperature source to a higher temperature sink using external work, enabling temperature control and energy recovery. Both technologies play crucial roles in process heating and cooling, but heat exchangers primarily facilitate passive heat transfer, whereas heat pumps actively upgrade thermal energy.

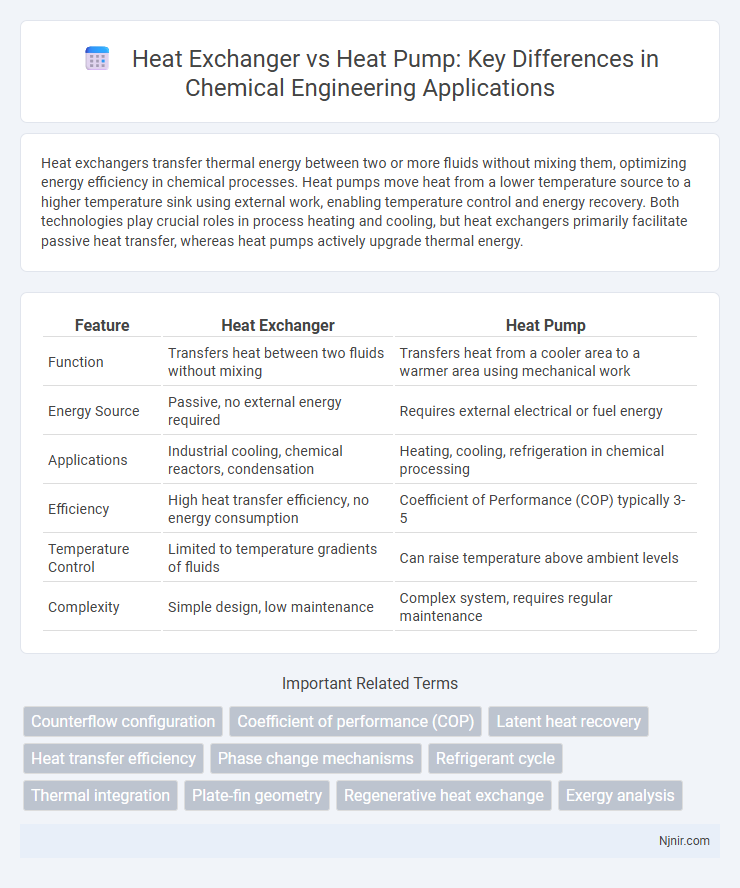

Table of Comparison

| Feature | Heat Exchanger | Heat Pump |

|---|---|---|

| Function | Transfers heat between two fluids without mixing | Transfers heat from a cooler area to a warmer area using mechanical work |

| Energy Source | Passive, no external energy required | Requires external electrical or fuel energy |

| Applications | Industrial cooling, chemical reactors, condensation | Heating, cooling, refrigeration in chemical processing |

| Efficiency | High heat transfer efficiency, no energy consumption | Coefficient of Performance (COP) typically 3-5 |

| Temperature Control | Limited to temperature gradients of fluids | Can raise temperature above ambient levels |

| Complexity | Simple design, low maintenance | Complex system, requires regular maintenance |

Introduction to Heat Exchangers and Heat Pumps

Heat exchangers transfer thermal energy between two or more fluids without mixing them, enabling efficient temperature regulation in industrial and HVAC systems. Heat pumps actively move heat from a cooler space to a warmer one using mechanical work, optimizing energy use in heating and cooling applications. Both technologies are crucial for energy management but operate on different principles and serve distinct purposes in temperature control.

Core Principles and Mechanisms

Heat exchangers transfer thermal energy between two or more fluids without mixing them, relying on conduction and convection principles to facilitate efficient heat transfer across surfaces or walls. Heat pumps operate by extracting heat from a low-temperature source and transferring it to a higher-temperature sink using a refrigeration cycle that involves evaporation, compression, condensation, and expansion of a working fluid. While heat exchangers passively transfer existing heat, heat pumps actively move heat against its natural gradient, enabling heating or cooling with electrical energy input.

Key Differences in Functionality

Heat exchangers transfer thermal energy between two or more fluids without mixing them, primarily enabling efficient temperature regulation in industrial processes and HVAC systems. Heat pumps actively move heat from a colder area to a warmer area using mechanical work, providing both heating and cooling by exploiting refrigeration cycles. While heat exchangers rely on passive heat transfer through conduction and convection, heat pumps depend on compressors, refrigerants, and expansion valves to achieve temperature control.

Applications in Chemical Engineering Processes

Heat exchangers are crucial in chemical engineering for transferring thermal energy between process streams, optimizing reactions, and maintaining temperature control in reactors and distillation columns. Heat pumps enhance energy efficiency by upgrading low-grade heat to higher temperatures, enabling heat recovery and reducing energy consumption in processes such as solvent recovery and drying. Integrating heat exchangers with heat pumps improves process sustainability by minimizing thermal energy waste and lowering operational costs in chemical plants.

Energy Efficiency Comparison

Heat pumps typically offer higher energy efficiency than heat exchangers by transferring heat using electrical energy with coefficients of performance (COP) ranging from 3 to 5, meaning they deliver three to five times more energy than they consume. Heat exchangers operate by transferring existing thermal energy between fluids without additional energy input, but their efficiency depends on temperature gradients and can be limited by heat loss and fouling. For sustainable energy management, heat pumps are preferable in applications requiring active heating or cooling, while heat exchangers are more efficient in passive heat recovery situations.

Design and Operational Considerations

Heat exchangers are designed to transfer thermal energy between two or more fluids without mixing, focusing on maximizing surface area and material conductivity for efficient heat transfer in applications such as HVAC systems and industrial processes. Heat pumps combine heat exchange with refrigeration cycles to move heat from a lower temperature source to a higher temperature sink, requiring components like compressors, evaporators, and condensers optimized for energy efficiency and seasonal demand variations. Operationally, heat exchangers maintain continuous fluid flow with minimal energy input, while heat pumps rely on electrical power to drive phase change cycles, making their performance dependent on ambient temperature conditions and refrigerant properties.

Integration With Industrial Systems

Heat exchangers seamlessly integrate with industrial systems by transferring thermal energy between fluids without mixing, optimizing processes such as chemical reactions, HVAC, and power generation. Heat pumps enhance industrial energy efficiency by extracting ambient or waste heat and upgrading it to higher temperatures for process heating or cooling applications. Combining both technologies allows industries to recycle heat more effectively, reducing overall energy consumption and operational costs.

Economic Analysis and Cost Factors

Heat exchangers typically involve lower initial investment and maintenance costs compared to heat pumps, making them more economical for simple heat transfer applications. Heat pumps, while more expensive upfront due to advanced components and technology, offer higher energy efficiency and can reduce operational costs significantly over time through energy savings. Economic analysis should account for lifecycle costs, including installation, energy consumption, maintenance, and potential energy rebates when comparing heat exchanger and heat pump systems.

Environmental Impact and Sustainability

Heat pumps offer significant environmental benefits by using renewable energy sources to transfer heat, resulting in lower greenhouse gas emissions compared to conventional heat exchangers that primarily rely on fossil fuels for heating and cooling processes. Heat exchangers contribute to energy efficiency by recovering waste heat in industrial settings but often depend on energy inputs with higher carbon footprints, limiting their overall sustainability. Implementing heat pumps in residential and commercial applications can reduce dependency on non-renewable energy, supporting carbon neutrality goals and enhancing long-term sustainability efforts.

Selection Criteria for Chemical Engineers

Chemical engineers prioritize factors such as thermal efficiency, operating temperature range, and maintenance requirements when selecting between heat exchangers and heat pumps. Heat exchangers excel in high-temperature processes and direct heat transfer applications, while heat pumps offer energy-efficient heating and cooling through phase change mechanisms at moderate temperatures. Material compatibility, system integration complexity, and cost-effectiveness remain critical in optimizing process performance and sustainability.

Counterflow configuration

Counterflow heat exchangers maximize thermal efficiency by allowing fluids to flow in opposite directions, whereas heat pumps use mechanical work to transfer heat, making counterflow designs ideal for optimizing heat recovery in exchangers but less relevant for heat pump operation.

Coefficient of performance (COP)

Heat pumps typically achieve a higher Coefficient of Performance (COP) than heat exchangers because they transfer heat by consuming less electrical energy relative to the heat delivered.

Latent heat recovery

Heat exchangers enable latent heat recovery by transferring moisture-laden air's latent heat between streams, while heat pumps actively extract and upgrade latent heat for efficient heating or cooling purposes.

Heat transfer efficiency

Heat pumps generally achieve higher heat transfer efficiency than heat exchangers by actively transferring thermal energy using mechanical work rather than relying solely on passive conduction or convection.

Phase change mechanisms

Heat exchangers transfer thermal energy between fluids without phase change, while heat pumps utilize phase change mechanisms in refrigerants to absorb and release heat efficiently.

Refrigerant cycle

A heat pump transfers heat using a refrigerant cycle that compresses and expands the refrigerant to move heat between indoor and outdoor environments, while a heat exchanger only facilitates heat transfer between two fluids without changing the refrigerant state.

Thermal integration

Heat pumps optimize thermal integration by transferring heat between systems for efficient energy use, whereas heat exchangers solely facilitate heat transfer without active heat pumping, making heat pumps more effective in dynamic thermal management.

Plate-fin geometry

Plate-fin geometry in heat exchangers enhances surface area and thermal efficiency, while heat pumps utilize similar designs to optimize heat transfer during heating and cooling cycles.

Regenerative heat exchange

Regenerative heat exchangers enhance thermal efficiency by cyclically storing and transferring heat within a medium, differing from heat pumps that actively transfer heat using mechanical work.

Exergy analysis

Exergy analysis reveals that heat pumps generally achieve higher thermodynamic efficiency than heat exchangers by minimizing irreversibilities and maximizing useful energy transfer.

heat exchanger vs heat pump Infographic

njnir.com

njnir.com