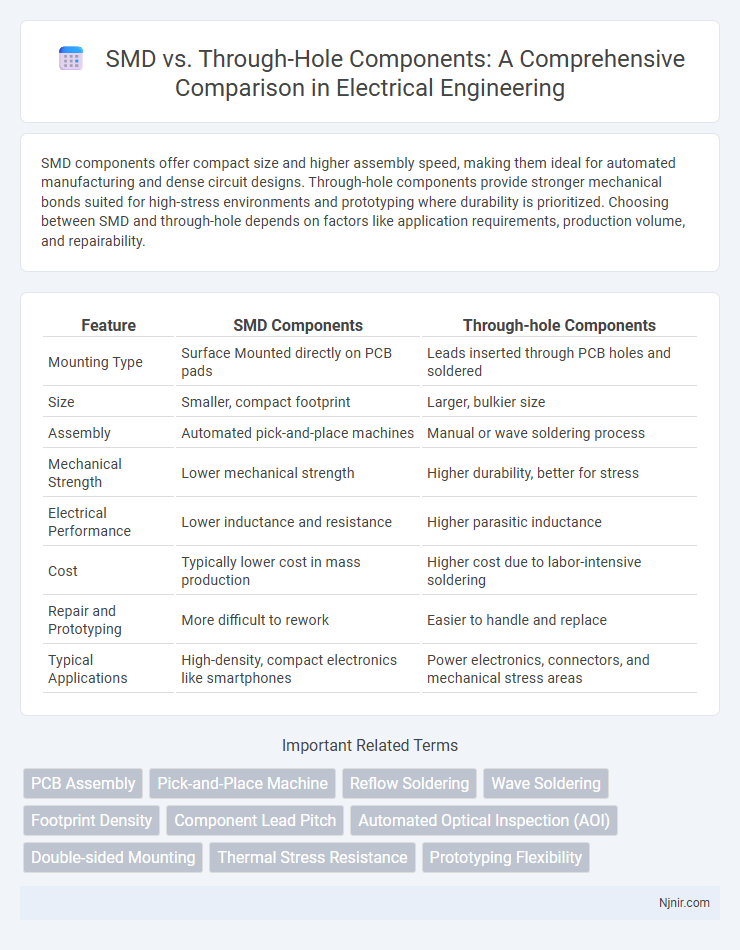

SMD components offer compact size and higher assembly speed, making them ideal for automated manufacturing and dense circuit designs. Through-hole components provide stronger mechanical bonds suited for high-stress environments and prototyping where durability is prioritized. Choosing between SMD and through-hole depends on factors like application requirements, production volume, and repairability.

Table of Comparison

| Feature | SMD Components | Through-hole Components |

|---|---|---|

| Mounting Type | Surface Mounted directly on PCB pads | Leads inserted through PCB holes and soldered |

| Size | Smaller, compact footprint | Larger, bulkier size |

| Assembly | Automated pick-and-place machines | Manual or wave soldering process |

| Mechanical Strength | Lower mechanical strength | Higher durability, better for stress |

| Electrical Performance | Lower inductance and resistance | Higher parasitic inductance |

| Cost | Typically lower cost in mass production | Higher cost due to labor-intensive soldering |

| Repair and Prototyping | More difficult to rework | Easier to handle and replace |

| Typical Applications | High-density, compact electronics like smartphones | Power electronics, connectors, and mechanical stress areas |

Introduction to SMD and Through-hole Components

Surface-mount devices (SMD) are compact electronic components designed for direct placement on printed circuit board (PCB) surfaces, enabling higher circuit density and automated assembly. Through-hole components feature leads inserted into drilled holes on the PCB, offering stronger mechanical bonds ideal for high-stress applications and prototyping. The choice between SMD and through-hole components affects assembly methods, board space utilization, and manufacturing costs in electronic design.

Historical Evolution of Electronic Component Mounting

The historical evolution of electronic component mounting transitioned from through-hole components dominating early electronics due to ease of manual assembly and reliable mechanical connections, to surface-mount devices (SMD) gaining prominence in the late 20th century with advancements in automated manufacturing and miniaturization. Through-hole technology was prevalent during the mid-1900s, especially in vacuum tube replacement era, favoring robust connections on multi-layered PCBs, while SMD emerged in the 1980s to meet demands for higher circuit density and improved performance in consumer electronics. This shift revolutionized PCB design, enabling compact, lightweight devices with enhanced electrical characteristics and manufacturing efficiency.

Structural Differences: SMD vs Through-hole

Surface mount devices (SMD) have flat, compact bodies with leads or terminals designed to be mounted directly onto the surface of printed circuit boards (PCBs), allowing for higher component density and automated placement. Through-hole components feature long leads that pass through drilled holes in the PCB, providing stronger mechanical bonds and better suited for high-reliability applications or environments with mechanical stress. The structural difference between SMD and through-hole components significantly affects assembly methods, electrical performance, and durability, with SMD favoring miniaturization and throughput efficiency while through-hole ensures robustness and ease of prototyping.

Assembly and Manufacturing Processes

Surface-mount device (SMD) components enable faster assembly through automated pick-and-place machines and reflow soldering, significantly reducing production time compared to traditional through-hole technology. Through-hole components require manual insertion or wave soldering, making the manufacturing process more labor-intensive and less compatible with high-density PCB designs. SMD assembly supports higher component density and miniaturization, optimizing mass production efficiency and cost-effectiveness.

Electrical Performance Comparison

Surface-mount devices (SMD) typically offer superior electrical performance compared to through-hole components due to shorter lead lengths, which reduce parasitic inductance and capacitance, enhancing high-frequency response. The smaller size and lower profile of SMDs enable better signal integrity and faster switching speeds, crucial in RF and high-speed digital circuits. Through-hole components, while robust for mechanical stability, often exhibit higher lead inductance and slower transient response, making them less optimal for precision and high-frequency applications.

Reliability and Durability Factors

Surface-mount devices (SMD) typically offer higher reliability in high-vibration and thermal cycling environments due to their smaller size and better mechanical bonding to PCB pads, reducing the risk of solder joint fatigue compared to through-hole components. Through-hole components provide superior mechanical strength for heavy or high-stress applications, as their leads pass through the PCB, ensuring robust physical connections especially in military or aerospace-grade equipment. Durability factors favor SMDs in compact, high-density circuits where exposure to shock and vibration is moderate, while through-hole designs remain preferred for applications requiring enhanced mechanical endurance and easier manual inspection or repair.

Cost Implications and Production Scalability

Surface-mount devices (SMD) reduce manufacturing costs due to automated assembly processes and smaller component sizes, which lower material usage and enable higher circuit density. Through-hole components require more manual labor and longer production times, increasing labor costs and limiting scalability for large-volume manufacturing. SMD technology supports rapid production scaling with automated pick-and-place machines, while through-hole assembly is typically slower and less cost-effective for mass production.

Suitability for Automation and Miniaturization

Surface-mount devices (SMD) are highly suitable for automation due to their small size and compatibility with high-speed pick-and-place machines, enabling efficient mass production. Through-hole components, while offering stronger mechanical bonds ideal for heavy or high-stress applications, are less amenable to automated assembly and require manual or wave soldering processes. SMD technology supports miniaturization with compact footprints and dual-sided PCB mounting, making it the preferred choice for modern electronics demanding reduced size and increased component density.

Application Areas and Industry Trends

Surface-mount devices (SMD) dominate in high-density applications like smartphones, laptops, and aerospace electronics due to their compact size and automated assembly compatibility. Through-hole components remain prevalent in power electronics, automotive, and military industries where mechanical strength and durability are critical. Industry trends show increasing SMD adoption driven by miniaturization and IoT growth, while through-hole is maintained for specialized, high-reliability uses.

Future Outlook in Electronic Component Technology

SMD components dominate miniaturization trends with enhanced performance in compact circuit designs, driving advancements in high-frequency and IoT applications. Through-hole technology remains relevant for durability and high-reliability sectors such as aerospace and automotive, where mechanical strength is critical. Future developments emphasize hybrid assembly techniques, integrating both SMD and through-hole elements to optimize space, thermal management, and reliability in evolving electronic systems.

PCB Assembly

Surface-mount devices (SMD) enable higher component density and faster PCB assembly than through-hole components due to automated placement and reflow soldering techniques.

Pick-and-Place Machine

Pick-and-place machines efficiently handle SMD components due to their smaller size and automated placement capabilities, whereas through-hole components often require manual insertion or specialized equipment.

Reflow Soldering

Reflow soldering is primarily used for surface-mount devices (SMD) due to their smaller size and automated placement, offering faster production and better heat control compared to through-hole components.

Wave Soldering

Wave soldering is more efficient for through-hole components due to their leaded design, while surface mount devices (SMDs) typically require reflow soldering for optimal assembly quality.

Footprint Density

Surface-mount device (SMD) components achieve higher footprint density compared to through-hole components by allowing smaller package sizes and closer placement on printed circuit boards (PCBs).

Component Lead Pitch

SMD components feature a smaller lead pitch typically ranging from 0.5mm to 1.27mm, enabling higher component density and more compact PCB designs compared to the larger, spaced leads of through-hole components.

Automated Optical Inspection (AOI)

Automated Optical Inspection (AOI) systems provide higher accuracy and faster defect detection for Surface-Mount Devices (SMD) compared to Through-hole components due to their smaller size and more consistent placement patterns.

Double-sided Mounting

Double-sided mounting enables efficient use of PCB space by integrating both SMD and through-hole components on opposite sides, enhancing circuit density and performance.

Thermal Stress Resistance

SMD components exhibit superior thermal stress resistance compared to through-hole components due to their smaller size, lower mass, and efficient heat dissipation, reducing the risk of damage during soldering and operation.

Prototyping Flexibility

SMD components offer greater prototyping flexibility through compact design, easier automation, and faster assembly compared to larger, manually soldered through-hole components.

SMD vs Through-hole Components Infographic

njnir.com

njnir.com