Thermal relays operate based on the heat generated by current flow, providing reliable protection against overload by tripping when excessive temperature is detected. Electronic relays utilize semiconductor components and sensors for precise, faster response times with adjustable settings for overload, short circuit, and phase failure protection. The choice between thermal and electronic relays depends on application requirements, with thermal relays favored for simple, low-cost solutions and electronic relays preferred for advanced, sensitive control systems.

Table of Comparison

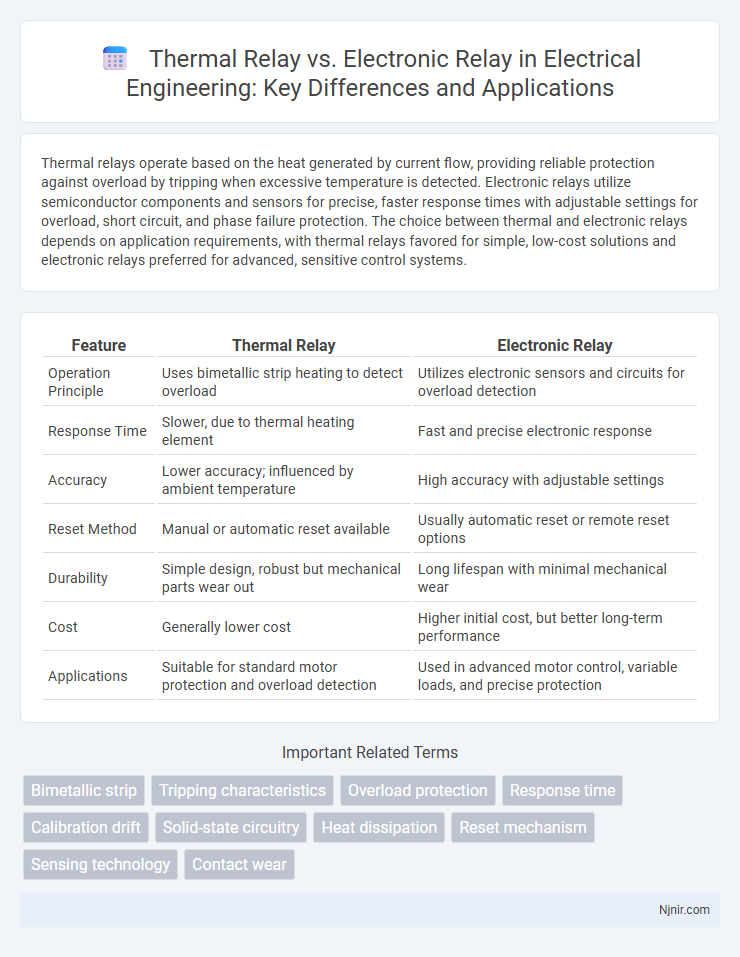

| Feature | Thermal Relay | Electronic Relay |

|---|---|---|

| Operation Principle | Uses bimetallic strip heating to detect overload | Utilizes electronic sensors and circuits for overload detection |

| Response Time | Slower, due to thermal heating element | Fast and precise electronic response |

| Accuracy | Lower accuracy; influenced by ambient temperature | High accuracy with adjustable settings |

| Reset Method | Manual or automatic reset available | Usually automatic reset or remote reset options |

| Durability | Simple design, robust but mechanical parts wear out | Long lifespan with minimal mechanical wear |

| Cost | Generally lower cost | Higher initial cost, but better long-term performance |

| Applications | Suitable for standard motor protection and overload detection | Used in advanced motor control, variable loads, and precise protection |

Introduction to Thermal and Electronic Relays

Thermal relays operate based on the heat generated by electric current, utilizing bimetallic strips that bend when heated to break or close circuits, providing reliable protection against overloads. Electronic relays use semiconductor components and integrated circuits to detect current changes with high precision and faster response times, enabling advanced control and monitoring functions. Both relays serve critical roles in electrical systems, but electronic relays offer enhanced sensitivity and programmability over traditional thermal relays.

Working Principles: Thermal vs Electronic Relays

Thermal relays operate based on the heating effect of electric current, using a bimetallic strip that bends when heated to break the circuit and protect against overloads. Electronic relays employ semiconductor components and microprocessors to detect current variations, providing faster and more precise responses without relying on temperature changes. The fundamental difference lies in thermal relays' reliance on mechanical heat-induced movement versus electronic relays' use of solid-state sensing and control technology.

Key Features and Functional Differences

Thermal relays operate based on heat generated by current flow, providing overload protection by tripping when temperature exceeds a preset limit, making them suitable for motor protection in heavy-duty applications. Electronic relays use solid-state components to detect current anomalies with higher precision, faster response times, and programmable settings, allowing for advanced features like remote monitoring and adjustable trip currents. While thermal relays excel in simplicity and robustness, electronic relays offer enhanced accuracy, flexibility, and integration with digital control systems.

Application Areas in Electrical Engineering

Thermal relays are predominantly used in motor protection applications, where they safeguard against overloads by detecting excess current through heat buildup, making them ideal for industrial machinery and HVAC systems. Electronic relays excel in precise and fast switching operations within automation, control panels, and smart grid technologies due to their advanced sensing and programmable features. Both types play critical roles in electrical engineering by enhancing system reliability and safety across manufacturing plants, power distribution networks, and automated processes.

Response Time and Sensitivity Comparison

Thermal relays exhibit slower response times due to their reliance on heat buildup for activation, typically ranging from several seconds to minutes, which makes them less sensitive to rapid current fluctuations. Electronic relays offer significantly faster response times, often measured in milliseconds, allowing for precise and instantaneous detection of electrical overloads and faults. Sensitivity in electronic relays is higher as they can detect minimal current variations through electronic circuitry, whereas thermal relays respond mainly to prolonged overcurrent conditions based on temperature rise.

Reliability and Maintenance Considerations

Thermal relays offer high reliability in overload protection due to their simple mechanical design, but they require routine calibration and inspection to maintain optimal performance. Electronic relays provide enhanced accuracy and faster response times with minimal mechanical wear, reducing maintenance frequency and improving long-term reliability. However, electronic relays can be more sensitive to voltage fluctuations and environmental factors, necessitating specialized diagnostics and firmware updates.

Cost Analysis: Installation and Operation

Thermal relays generally offer lower upfront installation costs due to simpler design and ease of integration in traditional motor protection circuits. Electronic relays, while having higher initial costs, provide greater accuracy and flexible settings that can reduce long-term operational expenses through improved energy efficiency and reduced downtime. Maintenance for thermal relays tends to be more frequent and costly, whereas electronic relays benefit from longer service intervals and lower associated labor costs over the device lifespan.

Protection Capabilities and Safety Aspects

Thermal relays provide protection by responding to overcurrent through temperature rise, offering reliable protection against motor overheating and phase failure but with slower response times. Electronic relays feature advanced protection capabilities such as adjustable trip settings, precise current measurement, and faster fault detection, enhancing safety by minimizing damage and downtime. Both relays improve safety, but electronic relays deliver superior protection through higher accuracy and quicker fault isolation.

Advancements in Relay Technology

Thermal relays rely on bimetallic strips that respond to heat generated by current flow, offering simple overload protection but limited accuracy and slower response times. Electronic relays utilize solid-state components and microprocessors, providing precise current monitoring, faster trip settings, and programmable features for enhanced protection and diagnostic capabilities. Advances in relay technology have enabled electronic relays to support smart grid integration, remote monitoring, and adaptive protection schemes, significantly improving reliability and efficiency in modern electrical systems.

Choosing the Right Relay for Your Application

Thermal relays are ideal for protecting motors against overloads by using a bimetallic strip that responds to heat, making them reliable for applications with fluctuating load conditions. Electronic relays offer precise control and faster response times through solid-state components, suitable for applications requiring quick switching and advanced diagnostic capabilities. Selecting the right relay depends on factors such as response speed, load type, accuracy requirements, and environmental conditions to ensure optimal protection and performance.

Bimetallic strip

A thermal relay uses a bimetallic strip that bends when heated by excess current to mechanically trigger a circuit break, whereas an electronic relay relies on semiconductor components without mechanical parts for faster and more precise overload protection.

Tripping characteristics

Thermal relays trip based on heat generated by current overload causing bimetallic strip bending with a slow inverse time delay, while electronic relays use solid-state sensors for precise, programmable, and faster tripping characteristics with adjustable time-current curves.

Overload protection

Thermal relays protect motors from overload by using bimetallic strips that bend with heat, while electronic relays detect overload through precise current sensing and adjustable trip settings for faster and more accurate protection.

Response time

Electronic relays provide faster response times than thermal relays, making them more suitable for applications requiring precise and rapid protection.

Calibration drift

Thermal relays experience significant calibration drift due to temperature fluctuations and aging of bimetallic strips, whereas electronic relays maintain precise calibration over time with minimal drift thanks to solid-state components and digital circuitry.

Solid-state circuitry

Solid-state circuitry in electronic relays offers faster switching, higher precision, and enhanced durability compared to the thermal delay and mechanical components of thermal relays.

Heat dissipation

Thermal relays dissipate heat through bimetallic strips reacting to current-induced temperature changes, whereas electronic relays use semiconductor components with integrated heat sinks for more efficient and controlled heat dissipation.

Reset mechanism

Thermal relays use a bimetallic strip that resets manually after cooling, while electronic relays feature automatic or remote reset capabilities through digital control circuits.

Sensing technology

Thermal relays use bimetallic strips that bend with temperature changes to sense overloads, while electronic relays utilize semiconductor sensors and microprocessors for precise current monitoring and faster response.

Contact wear

Thermal relays cause more contact wear due to mechanical operation and heat stress, while electronic relays minimize contact wear with solid-state switching components.

Thermal relay vs Electronic relay Infographic

njnir.com

njnir.com