KPIs (Key Performance Indicators) measure specific operational metrics crucial for monitoring ongoing performance in industrial engineering processes. OKRs (Objectives and Key Results) align broader strategic goals with measurable outcomes, driving innovation and continuous improvement within manufacturing systems. Integrating KPIs with OKRs enhances decision-making by linking day-to-day efficiency metrics to long-term organizational objectives.

Table of Comparison

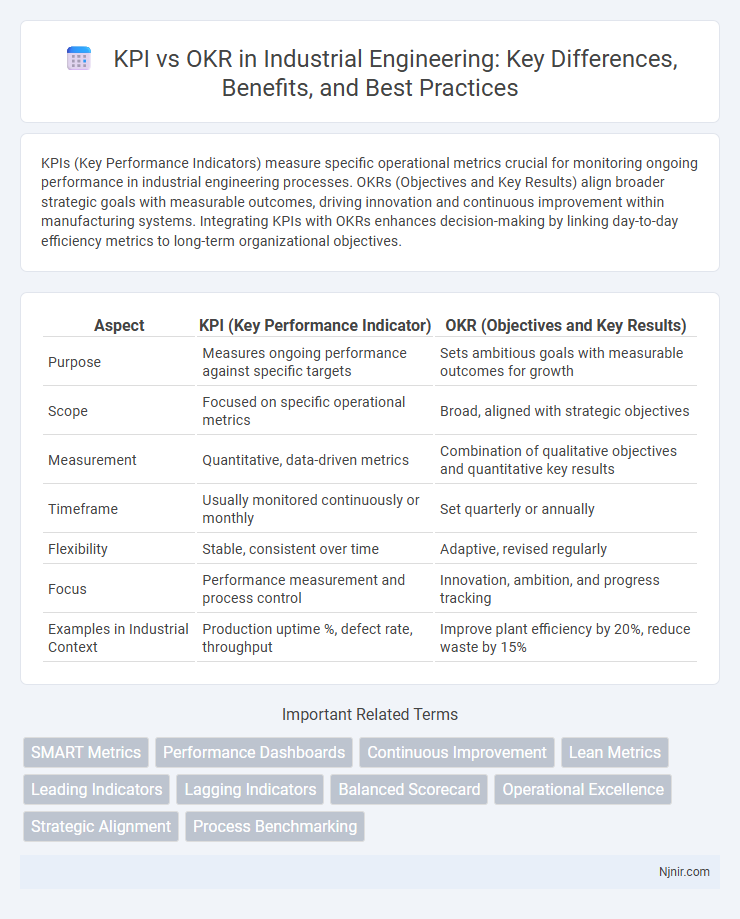

| Aspect | KPI (Key Performance Indicator) | OKR (Objectives and Key Results) |

|---|---|---|

| Purpose | Measures ongoing performance against specific targets | Sets ambitious goals with measurable outcomes for growth |

| Scope | Focused on specific operational metrics | Broad, aligned with strategic objectives |

| Measurement | Quantitative, data-driven metrics | Combination of qualitative objectives and quantitative key results |

| Timeframe | Usually monitored continuously or monthly | Set quarterly or annually |

| Flexibility | Stable, consistent over time | Adaptive, revised regularly |

| Focus | Performance measurement and process control | Innovation, ambition, and progress tracking |

| Examples in Industrial Context | Production uptime %, defect rate, throughput | Improve plant efficiency by 20%, reduce waste by 15% |

Understanding KPIs and OKRs in Industrial Engineering

KPIs (Key Performance Indicators) in industrial engineering measure specific operational efficiency metrics such as production rate, defect ratio, and machine downtime, providing quantifiable data to assess performance. OKRs (Objectives and Key Results) set strategic goals like improving supply chain responsiveness or reducing waste, paired with measurable results to track progress and align team efforts. Understanding the distinction and integration of KPIs and OKRs enables industrial engineers to monitor ongoing performance while driving impactful improvements across manufacturing processes.

Key Differences Between KPIs and OKRs

KPIs (Key Performance Indicators) measure specific metrics to evaluate ongoing performance against set targets, focusing on efficiency and outcomes. OKRs (Objectives and Key Results) define ambitious objectives accompanied by measurable key results, driving alignment and progress through transparent goals. KPIs track performance quantitatively, while OKRs encourage strategic initiatives and continuous improvement through qualitative and quantitative targets.

The Role of KPIs in Industrial Performance Measurement

Key Performance Indicators (KPIs) serve as quantifiable metrics essential for monitoring industrial performance, providing real-time data on operational efficiency, production quality, and resource utilization. KPIs enable companies to track progress toward strategic goals by measuring specific parameters such as equipment uptime, defect rates, and energy consumption. This data-driven approach allows industrial managers to identify bottlenecks, optimize processes, and drive continuous improvement across manufacturing operations.

OKRs: Driving Strategic Alignment in Industrial Operations

OKRs (Objectives and Key Results) are essential for driving strategic alignment in industrial operations by linking ambitious objectives with measurable outcomes that propel organizational focus and agility. Unlike KPIs, which monitor ongoing performance metrics, OKRs foster cross-functional collaboration and continuous improvement by encouraging teams to set challenging goals aligned with the company's long-term vision. Implementing OKRs in industrial settings enhances transparency, accelerates decision-making, and ensures all operational units contribute directly to critical business priorities.

When to Use KPIs vs OKRs in Industrial Engineering

KPIs measure specific performance metrics such as production efficiency, downtime, and quality control, making them ideal for ongoing process monitoring in industrial engineering. OKRs set strategic objectives like reducing waste by 15% or improving supply chain responsiveness within a quarter, driving innovation and cross-functional alignment. Use KPIs for tracking operational stability and OKRs to pursue transformational goals that require coordinated efforts across multiple departments.

Benefits of Integrating KPIs and OKRs

Integrating KPIs and OKRs enhances organizational performance by aligning measurable key performance indicators with ambitious objectives and key results, fostering clear accountability and continuous progress tracking. This synergy drives data-informed decision-making and ensures that strategic goals are consistently translated into actionable, outcome-focused initiatives. Combining KPIs with OKRs promotes transparency, enhances employee engagement, and accelerates business growth through focused execution.

Common Challenges in Implementing KPIs and OKRs

Common challenges in implementing KPIs and OKRs include setting unclear or overly ambitious goals that hinder accurate performance measurement. Organizations often struggle with aligning individual objectives to overall business strategy, leading to fragmented efforts and reduced accountability. Insufficient communication and lack of continuous monitoring further impede the effective tracking and achievement of these performance frameworks.

Case Studies: KPI and OKR Success Stories in Industry

Case studies of KPI and OKR implementations reveal distinct success patterns in diverse industries, such as Google's use of OKRs to drive rapid innovation and alignment across teams, resulting in accelerated product development cycles. In contrast, companies like Coca-Cola leverage KPIs to monitor operational efficiency and market performance, enabling data-driven decisions that optimize supply chain management and marketing ROI. These real-world examples demonstrate how aligning strategic goals through OKRs or measuring progress via KPIs can significantly boost organizational performance and competitive advantage.

Best Practices for Defining Industrial KPIs and OKRs

Defining industrial KPIs requires clear alignment with operational goals, quantifiable metrics, and regular performance tracking to ensure production efficiency and quality. OKRs in industrial settings prioritize ambitious, measurable objectives paired with specific key results to drive innovation and continuous improvement. Best practices involve setting realistic yet challenging targets, fostering cross-functional collaboration, and continuously reviewing progress to adapt strategies and maintain competitiveness.

Future Trends: Evolving Metrics in Industrial Engineering

KPI and OKR methodologies are increasingly integrating AI-driven analytics and real-time data monitoring to enhance precision in industrial engineering performance metrics. Future trends emphasize predictive KPIs that adapt to operational changes alongside flexible OKRs that align with rapid innovation cycles and sustainability goals. This evolution supports dynamic, data-centric decision-making frameworks optimizing efficiency and strategic growth in industrial systems.

SMART Metrics

SMART metrics enhance KPI effectiveness by providing Specific, Measurable, Achievable, Relevant, and Time-bound criteria, while OKRs drive alignment and ambition through clearly defined Objectives and Key Results.

Performance Dashboards

Performance dashboards visualize KPIs to measure ongoing business metrics, while OKRs drive goal-setting with specific objectives and key results to track progress and outcomes effectively.

Continuous Improvement

KPI measures specific performance metrics to track progress, while OKR sets ambitious goals to drive continuous improvement and innovation.

Lean Metrics

KPI measures specific performance outcomes while OKR aligns Lean Metrics with strategic objectives to drive continuous improvement and innovation.

Leading Indicators

Leading indicators in OKRs drive proactive performance improvements while KPIs primarily measure historical outcomes.

Lagging Indicators

KPI lagging indicators measure past performance outcomes to evaluate overall business success, while OKR lagging indicators assess the achievement of specific, strategic objectives aligned with growth.

Balanced Scorecard

Balanced Scorecard integrates KPIs to measure performance outcomes while OKRs align objectives with measurable key results, enhancing strategic focus and organizational balance.

Operational Excellence

KPI tracks specific performance metrics to measure operational efficiency, while OKR aligns ambitious objectives with key results to drive continuous improvement and operational excellence.

Strategic Alignment

KPI measures specific performance metrics to track progress, while OKR sets ambitious objectives with key results to ensure strategic alignment and drive organizational focus.

Process Benchmarking

Process benchmarking leverages KPIs to measure performance efficiency while OKRs drive strategic alignment and continuous improvement in organizational processes.

KPI vs OKR Infographic

njnir.com

njnir.com