Zero defects aims to eliminate errors through rigorous quality control and continuous improvement, ensuring that processes produce flawless outputs. Poka-yoke complements this goal by implementing simple, fail-safe mechanisms designed to prevent mistakes before they occur. Together, they enhance industrial engineering by reducing defects, minimizing rework, and improving overall product reliability.

Table of Comparison

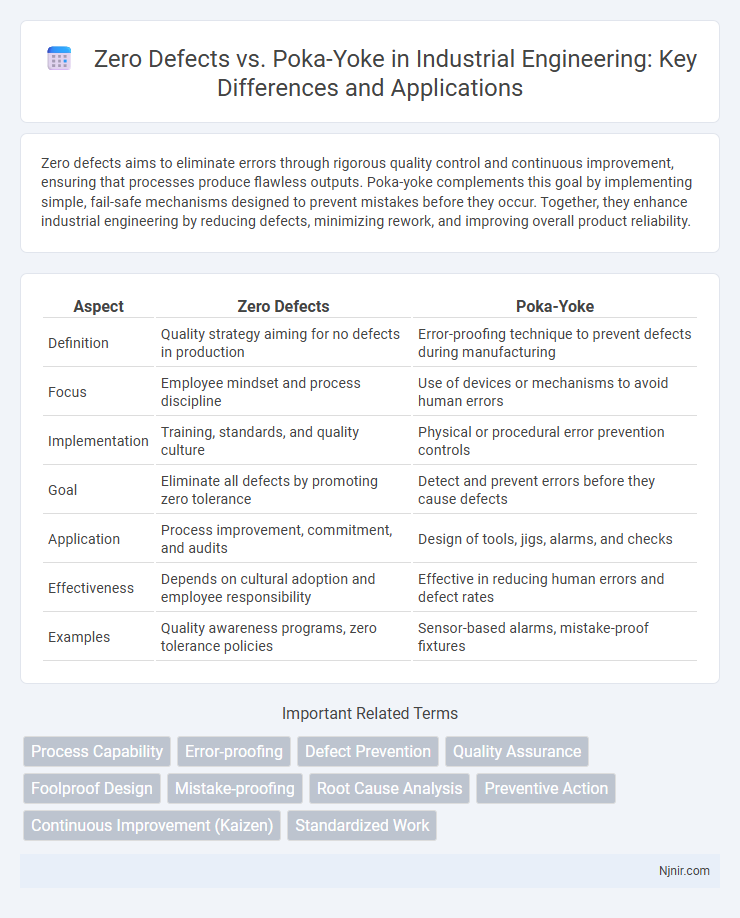

| Aspect | Zero Defects | Poka-Yoke |

|---|---|---|

| Definition | Quality strategy aiming for no defects in production | Error-proofing technique to prevent defects during manufacturing |

| Focus | Employee mindset and process discipline | Use of devices or mechanisms to avoid human errors |

| Implementation | Training, standards, and quality culture | Physical or procedural error prevention controls |

| Goal | Eliminate all defects by promoting zero tolerance | Detect and prevent errors before they cause defects |

| Application | Process improvement, commitment, and audits | Design of tools, jigs, alarms, and checks |

| Effectiveness | Depends on cultural adoption and employee responsibility | Effective in reducing human errors and defect rates |

| Examples | Quality awareness programs, zero tolerance policies | Sensor-based alarms, mistake-proof fixtures |

Understanding Zero Defects in Industrial Engineering

Zero Defects is a quality management philosophy aimed at reducing errors to zero through proactive process control and continuous improvement, essential in industrial engineering for maximizing product reliability and minimizing waste. Unlike Poka-yoke, which uses specific mistake-proofing devices or techniques to prevent errors at the source, Zero Defects emphasizes creating a culture of "doing it right the first time" by empowering employees and implementing robust quality systems. Both approaches are integral to industrial engineering, but Zero Defects prioritizes systemic process perfection while Poka-yoke provides tactical tools for immediate error prevention.

The Poka-Yoke Principle: Definition and Core Concepts

The Poka-Yoke principle, originating from Toyota's production system, emphasizes mistake-proofing processes to prevent errors before they occur, ensuring zero defects in manufacturing. This concept involves designing operations, tools, or workflows that automatically detect and correct human errors, thereby enhancing product quality and reducing waste. Poka-Yoke mechanisms include warning signals, physical constraints, and automated feedback systems that enforce correct performance and eliminate the risk of defects.

Historical Evolution of Zero Defects and Poka-Yoke

Zero Defects, pioneered by Philip Crosby in the 1960s, emphasizes a management-driven approach to achieving flawless quality through prevention and employee accountability. Poka-yoke, developed by Shigeo Shingo within the Toyota Production System in the 1960s and 1970s, introduced error-proofing mechanisms to automatically avoid defects during manufacturing. Both methodologies emerged as responses to industrial quality challenges, with Zero Defects focusing on cultural change and Poka-yoke on practical, in-process safeguards.

Key Differences Between Zero Defects and Poka-Yoke

Zero Defects is a quality management philosophy aimed at reducing errors by emphasizing a zero-error mindset and rigorous process control, while Poka-Yoke is a specific error-proofing technique designed to prevent mistakes during the manufacturing process. Zero Defects focuses on achieving perfection through continuous improvement and employee accountability, whereas Poka-Yoke involves implementing physical or procedural safeguards to automatically detect and correct errors. The key difference lies in Zero Defects' overarching cultural approach to quality, versus Poka-Yoke's practical tools and mechanisms to eliminate defects at the source.

Integrating Zero Defects Into Manufacturing Processes

Zero Defects emphasizes preventing errors by setting quality targets aimed at eliminating defects in manufacturing processes, while Poka-yoke provides practical mistake-proofing devices to detect and correct errors in real-time. Integrating Zero Defects into manufacturing requires implementing systematic quality management practices, such as Six Sigma and Total Quality Management, alongside Poka-yoke mechanisms to ensure continuous process improvement and error prevention. This combination enhances product reliability, reduces waste, and drives operational excellence by embedding quality control at every stage of production.

Poka-Yoke Techniques for Error Prevention

Poka-Yoke techniques focus on error prevention by designing processes that make it impossible or difficult to commit mistakes, thereby supporting zero defects in manufacturing and service workflows. These methods include mistake-proofing devices such as warning signals, physical barriers, and automatic shutdowns that detect and correct errors immediately. Implementing Poka-Yoke reduces defect rates, enhances product quality, and ensures consistent adherence to manufacturing standards.

Benefits of Implementing Zero Defects Strategies

Implementing Zero Defects strategies enhances product quality by minimizing errors and reducing rework costs, leading to higher customer satisfaction. These strategies promote a culture of continuous improvement and accountability, ensuring processes are streamlined and defects are prevented at the source. By achieving near-perfect quality levels, companies can improve operational efficiency, reduce waste, and strengthen their competitive advantage in the market.

Common Poka-Yoke Tools and Their Applications

Common Poka-Yoke tools include mistake-proofing devices such as checklists, control charts, and physical guides that prevent errors in manufacturing processes. These tools are widely applied in automotive assembly lines, electronics production, and packaging industries to detect defects early and reduce human error. Unlike the Zero Defects philosophy, which emphasizes error elimination through quality management, Poka-Yoke provides practical, real-time solutions ensuring process accuracy and product consistency.

Case Studies: Zero Defects vs Poka-Yoke in Industry

Case studies in manufacturing industries highlight Zero Defects as a proactive quality management philosophy aiming for flawless production by eliminating errors at the source, exemplified by Motorola's Six Sigma implementation that reduced defects to near zero. In contrast, Poka-Yoke emphasizes mistake-proofing techniques, as seen in Toyota's assembly lines where simple devices and visual cues prevent human errors before they occur. Both strategies complement each other by combining rigorous process control with practical error-prevention tools, significantly improving product quality and reducing waste.

Choosing the Right Approach: Zero Defects or Poka-Yoke?

Selecting between Zero Defects and Poka-Yoke hinges on the organization's quality management goals and operational context; Zero Defects emphasizes a culture of flawless output through continuous improvement and employee accountability, while Poka-Yoke focuses on mistake-proofing processes with practical error-prevention mechanisms. Implementing Zero Defects suits environments aiming for zero tolerance of defects at all stages, requiring rigorous training and proactive quality assurance systems. Poka-Yoke is ideal for production lines needing immediate, automated error detection and correction to minimize human mistakes and enhance process reliability.

Process Capability

Zero defects emphasize achieving near-perfect process capability by rigorously minimizing defects, while Poka-yoke enhances process capability through error-proofing mechanisms that prevent defects during production.

Error-proofing

Zero defects is a quality management philosophy aiming for flawless products, while Poka-yoke is an error-proofing technique designed to prevent or immediately detect mistakes during the manufacturing process.

Defect Prevention

Zero defects focuses on achieving flawless production through rigorous quality control, while Poka-yoke employs mistake-proofing techniques specifically designed to prevent defects during the manufacturing process.

Quality Assurance

Zero defects aims to eliminate all product flaws through rigorous quality control, while Poka-yoke implements error-proofing mechanisms to prevent mistakes during the manufacturing process within Quality Assurance.

Foolproof Design

Poka-yoke is a foolproof design technique within zero defects methodology that prevents errors by incorporating simple, fail-safe mechanisms to ensure process accuracy and product quality.

Mistake-proofing

Zero defects aims to eliminate all errors in processes while Poka-yoke specifically implements mistake-proofing techniques to prevent human errors from occurring.

Root Cause Analysis

Zero defects emphasizes preventing errors through stringent Root Cause Analysis while Poka-yoke implements real-time error-proofing mechanisms to immediately address defects at the source.

Preventive Action

Zero defects aims to eliminate errors through overall quality management, while Poka-yoke employs specific preventive actions using mistake-proofing devices to avoid defects at the source.

Continuous Improvement (Kaizen)

Zero defects and Poka-yoke both drive continuous improvement (Kaizen) by systematically eliminating errors and enhancing process reliability to achieve higher quality standards.

Standardized Work

Zero defects emphasizes achieving flawless output through rigorous quality standards while Poka-yoke implements error-proofing mechanisms within Standardized Work to prevent mistakes at the source.

Zero defects vs Poka-yoke Infographic

njnir.com

njnir.com