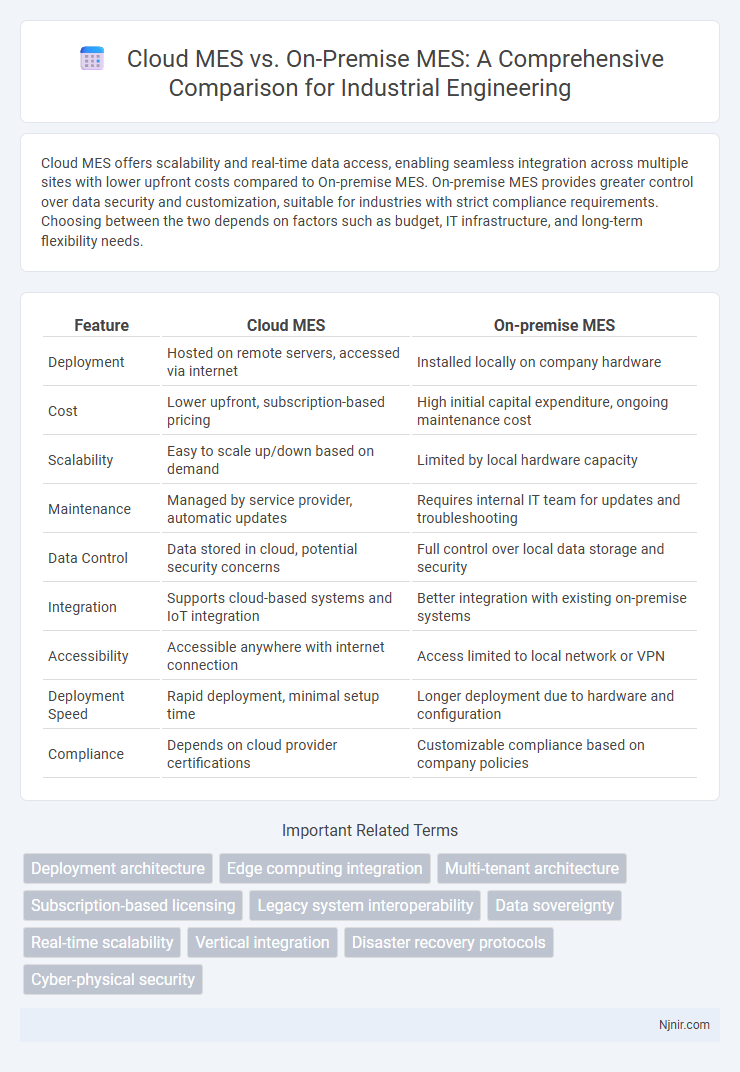

Cloud MES offers scalability and real-time data access, enabling seamless integration across multiple sites with lower upfront costs compared to On-premise MES. On-premise MES provides greater control over data security and customization, suitable for industries with strict compliance requirements. Choosing between the two depends on factors such as budget, IT infrastructure, and long-term flexibility needs.

Table of Comparison

| Feature | Cloud MES | On-premise MES |

|---|---|---|

| Deployment | Hosted on remote servers, accessed via internet | Installed locally on company hardware |

| Cost | Lower upfront, subscription-based pricing | High initial capital expenditure, ongoing maintenance cost |

| Scalability | Easy to scale up/down based on demand | Limited by local hardware capacity |

| Maintenance | Managed by service provider, automatic updates | Requires internal IT team for updates and troubleshooting |

| Data Control | Data stored in cloud, potential security concerns | Full control over local data storage and security |

| Integration | Supports cloud-based systems and IoT integration | Better integration with existing on-premise systems |

| Accessibility | Accessible anywhere with internet connection | Access limited to local network or VPN |

| Deployment Speed | Rapid deployment, minimal setup time | Longer deployment due to hardware and configuration |

| Compliance | Depends on cloud provider certifications | Customizable compliance based on company policies |

Introduction to MES in Industrial Engineering

Manufacturing Execution Systems (MES) are critical software solutions in industrial engineering that monitor, control, and optimize production processes on the shop floor. Cloud MES offers flexible, scalable deployment with real-time data accessibility and reduced IT infrastructure costs, while On-premise MES provides robust data security and customization tailored to specific factory requirements. Understanding the trade-offs between Cloud and On-premise MES enables manufacturers to enhance operational efficiency, quality control, and production transparency.

Key Features of Cloud MES Solutions

Cloud MES solutions offer real-time data accessibility, enabling seamless collaboration across multiple sites and improved decision-making through advanced analytics and AI integration. Scalability and automatic software updates reduce IT overhead and ensure continuous system improvements without disruption. Enhanced security protocols, compliance with industry standards, and flexible deployment options make Cloud MES ideal for dynamic manufacturing environments seeking agility and cost efficiency.

Core Capabilities of On-Premise MES

On-premise MES offers robust data security, real-time control, and customization tailored to specific manufacturing environments. It provides direct integration with existing enterprise systems and equipment, ensuring low latency and high reliability for critical production processes. Furthermore, on-premise MES enables companies to maintain full control over software updates and data governance, meeting strict compliance and regulatory requirements.

Deployment Speed and Flexibility Comparison

Cloud MES offers significantly faster deployment speeds, often enabling operational readiness within weeks due to its SaaS architecture and minimal hardware requirements. On-premise MES implementations typically require months for full deployment, involving extensive infrastructure setup and customization. Cloud MES provides greater flexibility with scalable resources and easier updates, while on-premise systems offer limited adaptability constrained by physical hardware and longer upgrade cycles.

Data Security and Compliance Considerations

Cloud MES offers scalable data encryption, automated backups, and continuous security updates, enhancing protection against cyber threats and ensuring compliance with global standards like ISO 27001 and GDPR. On-premise MES provides direct control over sensitive data, enabling tailored security measures and compliance with strict industry regulations such as FDA 21 CFR Part 11, but requires significant IT resources for maintenance. Organizations must weigh the benefits of cloud flexibility and real-time compliance monitoring against the control and customization of on-premise deployments to address their specific data security needs.

Cost Analysis: Cloud MES vs On-Premise MES

Cloud MES reduces upfront capital expenditures by eliminating the need for physical hardware and infrastructure, offering a subscription-based pricing model that scales with usage. On-premise MES requires significant initial investment in servers, software licenses, and ongoing maintenance costs, leading to higher total cost of ownership over time. Cloud MES provides predictable operational expenses and faster deployment, whereas on-premise MES incurs higher support and upgrade costs due to dedicated IT resource requirements.

Scalability and Integration in Modern Manufacturing

Cloud MES solutions offer superior scalability by enabling manufacturers to easily adjust resources based on production demands, supporting rapid expansion without significant capital investment. Integration capabilities with IoT devices, ERP systems, and advanced analytics platforms are streamlined in Cloud MES due to its centralized architecture and API-driven interfaces. On-premise MES provides control over data and customization but often faces limitations in scaling quickly and integrating with emerging technologies, which can hinder responsiveness in dynamic manufacturing environments.

Maintenance and Support Requirements

Cloud MES offers streamlined maintenance and support through automatic updates and remote troubleshooting managed by the provider, reducing the need for in-house IT staff. On-premise MES requires dedicated on-site personnel for regular maintenance, system upgrades, and immediate technical support, often leading to higher operational costs. Companies with limited IT resources benefit from the cloud model's scalability and continuous support, while those needing full system control may prefer on-premise solutions despite increased maintenance demands.

Real-Time Data Access and Analytics

Cloud MES offers superior real-time data access and analytics by leveraging continuous connectivity and centralized data storage, enabling instant visibility into production metrics across multiple sites. On-premise MES systems often face latency issues and limited scalability, restricting real-time insights and advanced analytics capabilities. Cloud-based solutions integrate AI-driven analytics and IoT data streams seamlessly, enhancing decision-making speed and operational efficiency compared to traditional on-premise deployments.

Future Trends in MES Deployment Models

Future trends in MES deployment models reveal a strong shift towards cloud MES due to its scalability, real-time data accessibility, and lower upfront costs, which align with Industry 4.0 demands. Hybrid MES solutions are emerging, combining cloud flexibility with on-premise control to address security and latency concerns in manufacturing environments. Advancements in edge computing and AI integration are expected to further enhance cloud MES capabilities, driving smarter, more adaptive production workflows.

Deployment architecture

Cloud MES utilizes a centralized, internet-based deployment architecture for scalable, accessible management, while On-premise MES relies on localized servers within a company's infrastructure, offering direct control but limited remote accessibility.

Edge computing integration

Cloud MES leverages seamless Edge computing integration for real-time data processing and enhanced scalability, whereas On-premise MES offers localized control with limited Edge connectivity and slower data analysis.

Multi-tenant architecture

Cloud MES leverages multi-tenant architecture to provide scalable, cost-effective, and easily maintainable solutions, while On-premise MES typically operates on single-tenant setups ensuring dedicated resources but higher infrastructure and maintenance costs.

Subscription-based licensing

Cloud MES offers scalable subscription-based licensing that reduces upfront costs and simplifies updates compared to the high initial investment and maintenance fees of on-premise MES.

Legacy system interoperability

Cloud MES offers enhanced legacy system interoperability through scalable APIs and cloud-based integration layers, whereas On-premise MES often requires complex custom interfaces and higher maintenance to connect with legacy equipment.

Data sovereignty

Cloud MES offers scalable solutions with potential data sovereignty challenges depending on cloud provider locations, while On-premise MES ensures complete local control over sensitive manufacturing data and compliance with regional regulations.

Real-time scalability

Cloud MES provides superior real-time scalability by enabling dynamic resource allocation and instant updates, unlike on-premise MES which is limited by fixed hardware capacity.

Vertical integration

Cloud MES enables seamless vertical integration by offering real-time data accessibility across all production levels, whereas On-premise MES often limits integration due to localized infrastructure and slower data sharing.

Disaster recovery protocols

Cloud MES offers automated, geographically distributed disaster recovery protocols ensuring minimal downtime and data loss, whereas On-premise MES relies on local backups and manual recovery processes that may extend recovery time and increase risk.

Cyber-physical security

Cloud MES offers enhanced cyber-physical security through real-time threat detection and remote updates, while on-premise MES provides localized control but requires manual security management and is more vulnerable to physical breaches.

Cloud MES vs On-premise MES Infographic

njnir.com

njnir.com