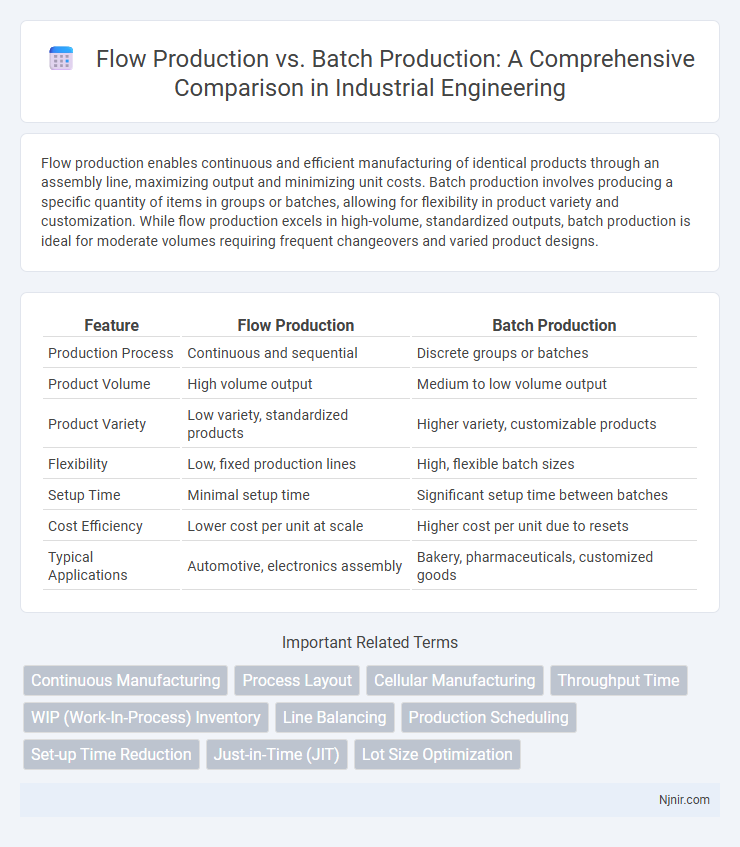

Flow production enables continuous and efficient manufacturing of identical products through an assembly line, maximizing output and minimizing unit costs. Batch production involves producing a specific quantity of items in groups or batches, allowing for flexibility in product variety and customization. While flow production excels in high-volume, standardized outputs, batch production is ideal for moderate volumes requiring frequent changeovers and varied product designs.

Table of Comparison

| Feature | Flow Production | Batch Production |

|---|---|---|

| Production Process | Continuous and sequential | Discrete groups or batches |

| Product Volume | High volume output | Medium to low volume output |

| Product Variety | Low variety, standardized products | Higher variety, customizable products |

| Flexibility | Low, fixed production lines | High, flexible batch sizes |

| Setup Time | Minimal setup time | Significant setup time between batches |

| Cost Efficiency | Lower cost per unit at scale | Higher cost per unit due to resets |

| Typical Applications | Automotive, electronics assembly | Bakery, pharmaceuticals, customized goods |

Introduction to Flow and Batch Production

Flow production involves continuous manufacturing of standardized products, maximizing efficiency through streamlined processes and minimal work-in-progress inventory. Batch production, on the other hand, produces goods in set quantities at a time, allowing flexibility to accommodate variations in product design and customer demand. Both methods are essential for different industries; flow production suits high-volume, uniform products while batch production is ideal for customized, smaller-scale orders.

Key Differences Between Flow and Batch Production

Flow production involves continuous, high-volume manufacturing of standardized products, ensuring consistent output and efficiency. Batch production produces goods in specific groups, allowing more flexibility and customization but with longer setup times and potential downtime between batches. Key differences focus on production speed, product uniformity, and operational flexibility, where flow excels in repetitive tasks and batch supports varied product lines.

Advantages of Flow Production in Industrial Engineering

Flow production significantly enhances efficiency by enabling continuous, streamlined manufacturing processes that reduce lead times and minimize work-in-progress inventory. The standardized, repetitive operations facilitate consistent product quality and lower per-unit costs through economies of scale. Automated machinery integration in flow production further boosts productivity and reduces labor variability, making it ideal for high-volume industrial engineering applications.

Benefits of Batch Production for Flexible Manufacturing

Batch production offers significant benefits for flexible manufacturing by allowing the production of varying product types in smaller quantities without extensive downtime or retooling. This method enhances responsiveness to market demand changes, supports customization, and reduces inventory costs compared to continuous flow production. Manufacturers achieve greater adaptability and efficiency by leveraging batch processes for diverse product lines or seasonal variations.

Limitations and Challenges of Flow Production

Flow production faces challenges such as high initial capital investment and inflexibility in product design changes, limiting responsiveness to market variations. The continuous process is vulnerable to disruptions, where a single breakdown can halt the entire production line, leading to significant downtime and loss. Maintaining quality control and workforce motivation in repetitive, monotonous tasks also presents ongoing difficulties in flow production systems.

Drawbacks Associated with Batch Production Systems

Batch production systems often face challenges such as longer lead times due to setup and changeover between batches, which reduces overall efficiency. There is a higher risk of inventory buildup and increased storage costs caused by fluctuating batch sizes and inconsistent workflow. Quality control can be more complex because defects may affect entire batches, leading to increased waste and rework.

Selecting the Right Production Method: Key Factors

Selecting the right production method hinges on factors like order size, product variety, and demand consistency; flow production excels in high-volume, standardized items with steady demand, while batch production suits moderate volumes and varied products requiring flexibility. Cost efficiency is pivotal, as flow production minimizes unit costs through continuous processes, whereas batch production reduces setup times for smaller runs. Lead time and customization also affect the decision, with flow production offering faster throughput and batch production enabling tailored outputs.

Technology Integration in Flow and Batch Production

Flow production leverages advanced automation technologies and real-time data analytics to maintain continuous product movement, enhancing efficiency and reducing downtime. Batch production integrates flexible manufacturing systems and digital tracking tools to manage varied product batches with precision and adaptability. Both production methods increasingly utilize IoT devices and AI-driven software to optimize workflow, quality control, and inventory management.

Cost Efficiency Analysis: Flow vs. Batch Production

Flow production minimizes unit costs through continuous processes and economies of scale, making it highly cost-efficient for high-volume, standardized products. Batch production incurs higher per-unit costs due to frequent setup changes and downtime but offers flexibility for varied product mixes and smaller volumes. Cost efficiency in flow production surpasses batch production when demand is stable and output volume is large, optimizing labor and material usage.

Future Trends in Industrial Production Systems

Future trends in industrial production systems emphasize the integration of Industry 4.0 technologies such as IoT, AI, and robotics to enhance flow production efficiency through real-time data analytics and automation. Batch production is evolving with modular manufacturing and flexible automation, enabling customized small-scale production while maintaining cost-effectiveness. The convergence of digital twins and smart factories supports a hybrid production model that balances continuous flow efficiency and batch flexibility to meet dynamic market demands.

Continuous Manufacturing

Continuous manufacturing in flow production enables uninterrupted, high-volume output by systematically moving products through consistent, streamlined processes, unlike batch production which relies on discrete, separate production runs.

Process Layout

Flow production utilizes a fixed, linear process layout for continuous product movement, while batch production employs a functional process layout allowing flexible, grouped operations for varied product batches.

Cellular Manufacturing

Cellular manufacturing integrates flow production principles within batch production by organizing workstations into cells that enable continuous, efficient workflows and minimize batch sizes.

Throughput Time

Flow production significantly reduces throughput time by continuously processing items, whereas batch production experiences longer throughput times due to sequential handling and setup between batches.

WIP (Work-In-Process) Inventory

Flow production minimizes WIP inventory by enabling continuous, streamlined processes, whereas batch production results in higher WIP inventory due to intermittent processing and stockpiling between stages.

Line Balancing

Flow production achieves higher efficiency through continuous line balancing that minimizes idle time, while batch production requires flexible line balancing to accommodate variable batch sizes and reduce setup delays.

Production Scheduling

Flow production scheduling maximizes continuous output by tightly coordinating sequential tasks, while batch production scheduling prioritizes flexible timing to accommodate varied product groups and changeovers.

Set-up Time Reduction

Reducing set-up time in flow production enhances continuous throughput by minimizing downtime between processes, while batch production experiences longer set-up times due to frequent changeovers for different product batches.

Just-in-Time (JIT)

Flow production enhances Just-in-Time (JIT) efficiency by continuously moving products through the manufacturing process, minimizing inventory and reducing lead times compared to batch production.

Lot Size Optimization

Optimizing lot size in flow production minimizes inventory and reduces setup times, while batch production requires balancing larger lot sizes to decrease frequency of setups against the risk of excess inventory and increased holding costs.

Flow Production vs Batch Production Infographic

njnir.com

njnir.com