Safety stock provides a buffer against demand variability and supply delays, reducing the risk of stockouts but increasing holding costs. Just-In-Time (JIT) inventory minimizes inventory levels by synchronizing production closely with demand, enhancing efficiency but requiring reliable suppliers and accurate demand forecasting. Balancing safety stock and JIT strategies optimizes inventory management, ensuring both cost control and service level objectives in industrial engineering.

Table of Comparison

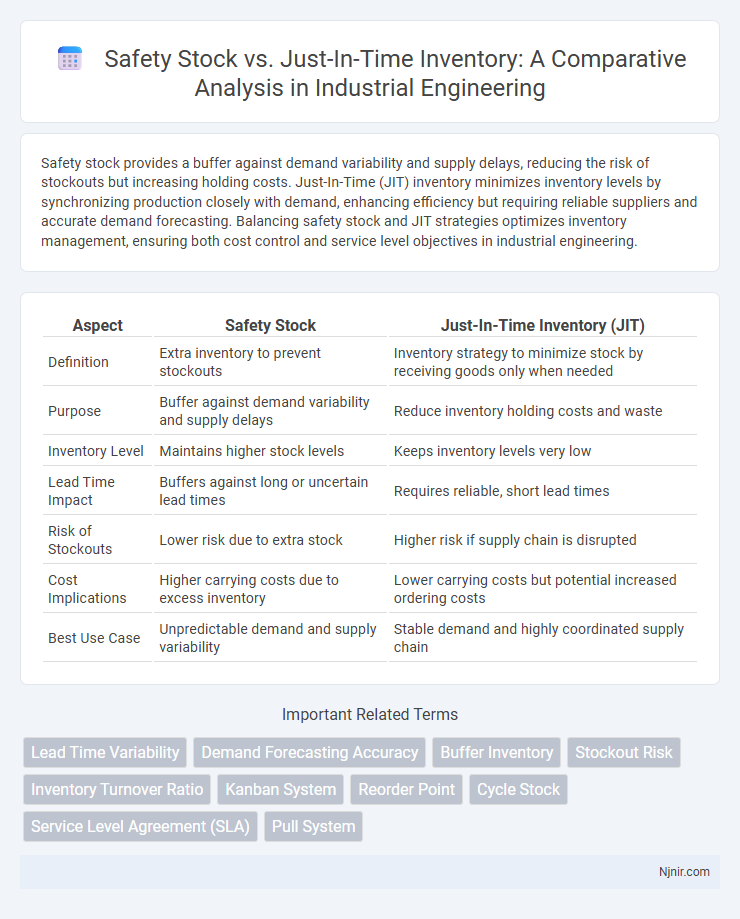

| Aspect | Safety Stock | Just-In-Time Inventory (JIT) |

|---|---|---|

| Definition | Extra inventory to prevent stockouts | Inventory strategy to minimize stock by receiving goods only when needed |

| Purpose | Buffer against demand variability and supply delays | Reduce inventory holding costs and waste |

| Inventory Level | Maintains higher stock levels | Keeps inventory levels very low |

| Lead Time Impact | Buffers against long or uncertain lead times | Requires reliable, short lead times |

| Risk of Stockouts | Lower risk due to extra stock | Higher risk if supply chain is disrupted |

| Cost Implications | Higher carrying costs due to excess inventory | Lower carrying costs but potential increased ordering costs |

| Best Use Case | Unpredictable demand and supply variability | Stable demand and highly coordinated supply chain |

Introduction to Inventory Management Strategies

Safety stock inventory acts as a buffer against demand variability and supply chain disruptions, ensuring product availability during unexpected delays or spikes in demand. Just-In-Time (JIT) inventory strategy minimizes holding costs by receiving goods only as needed in the production process, increasing efficiency and reducing waste. Balancing safety stock with JIT principles requires precise demand forecasting and reliable supplier relationships to optimize inventory levels and maintain seamless operations.

Defining Safety Stock: Purpose and Principles

Safety stock acts as a buffer inventory designed to protect against uncertainties in demand and supply variability, ensuring smooth operations and preventing stockouts. It is calculated based on factors such as lead time variability, demand fluctuations, and desired service levels to maintain customer satisfaction. The principle of safety stock centers on balancing inventory holding costs with the risk of lost sales or production interruptions due to insufficient stock.

Just-In-Time (JIT) Inventory: Concept and Core Elements

Just-In-Time (JIT) Inventory is a lean inventory strategy designed to increase efficiency by receiving goods only as they are needed in the production process, minimizing inventory holding costs. Core elements of JIT include precise demand forecasting, strong supplier relationships, and streamlined manufacturing processes to reduce waste and lead times. Effective JIT implementation requires synchronized production schedules, continuous improvement practices, and a firm commitment to quality control to avoid stockouts and maintain smooth operations.

Key Differences Between Safety Stock and JIT Inventory

Safety stock involves maintaining extra inventory to buffer against demand variability and supply chain disruptions, ensuring product availability despite uncertainties. Just-In-Time (JIT) inventory minimizes stock levels by synchronizing production schedules with demand, reducing holding costs and waste. Key differences include safety stock's focus on risk mitigation through surplus inventory, whereas JIT emphasizes efficiency and lean operations by delivering materials exactly when needed.

Advantages of Maintaining Safety Stock

Maintaining safety stock provides a critical buffer against demand fluctuations and supply chain disruptions, ensuring continuous production and customer satisfaction. It reduces the risk of stockouts, which can lead to lost sales and damaged brand reputation. Safety stock supports operational resilience by allowing companies to absorb delays from suppliers and unexpected increases in demand without halting operations.

Benefits of Implementing Just-In-Time Inventory

Just-In-Time (JIT) inventory minimizes holding costs by reducing excess stock and enhances cash flow efficiency through precise demand forecasting and streamlined supply chain management. This approach decreases waste, lowers storage space requirements, and increases responsiveness to market fluctuations, leading to improved overall operational agility. Companies adopting JIT benefit from leaner inventory practices that optimize working capital and boost customer satisfaction by ensuring timely product availability.

Risks and Drawbacks of Safety Stock Approaches

Safety stock helps mitigate risks of stockouts due to demand variability or supply delays but increases holding costs and potential obsolescence. Excessive safety stock ties up capital and reduces inventory turnover, impacting cash flow and storage capacity. Relying heavily on safety stock can mask inefficiencies in demand forecasting and supply chain responsiveness.

Challenges and Limitations of JIT Systems

Just-In-Time (JIT) inventory systems face challenges such as vulnerability to supply chain disruptions, which can halt production due to the absence of safety stock buffers. Limited flexibility in responding to sudden demand spikes often leads to stockouts and lost sales. Dependence on highly reliable suppliers and precise demand forecasting increases operational risks and complexity.

Industry-Specific Applications and Case Studies

Safety stock ensures buffer inventory to prevent stockouts in industries with variable demand, such as healthcare and automotive manufacturing, where supply chain disruptions can have critical consequences. Just-In-Time (JIT) inventory excels in sectors like electronics and fast fashion, minimizing holding costs by synchronizing production schedules with demand fluctuations. Case studies from Toyota highlight JIT's efficiency in reducing waste and improving cash flow, while pharmaceutical companies rely on safety stock to maintain continuous supply of essential drugs amid unpredictable demand.

Choosing the Right Inventory Strategy for Your Operations

Selecting the ideal inventory strategy depends on demand variability, lead times, and risk tolerance. Safety stock provides a buffer against supply chain disruptions, ensuring product availability but increasing holding costs. Just-In-Time inventory reduces excess stock and minimizes storage expenses by aligning orders closely with production schedules, ideal for stable demand and reliable suppliers.

Lead Time Variability

Safety stock buffers inventory against lead time variability by storing extra units, whereas Just-In-Time inventory minimizes stock by synchronizing deliveries to precise demand timing, reducing the impact of lead time fluctuations.

Demand Forecasting Accuracy

Safety stock mitigates risks from inaccurate demand forecasting by maintaining extra inventory, whereas Just-In-Time inventory minimizes stock levels by relying on highly precise demand forecasting to align supply with real-time demand.

Buffer Inventory

Buffer inventory in safety stock strategies ensures supply chain resilience by maintaining extra stock to prevent disruptions, contrasting with just-in-time inventory's minimal stock approach that reduces holding costs but increases vulnerability to demand variability.

Stockout Risk

Safety stock reduces stockout risk by maintaining buffer inventory, whereas Just-In-Time inventory minimizes stock levels but increases vulnerability to supply disruptions.

Inventory Turnover Ratio

Just-In-Time inventory maximizes inventory turnover ratio by minimizing stock levels, whereas safety stock reduces turnover ratio due to higher inventory holding.

Kanban System

The Kanban system enhances Just-In-Time inventory by visually controlling workflow and minimizing safety stock levels to reduce waste and improve efficiency.

Reorder Point

The reorder point in safety stock inventory systems accounts for demand variability and lead time to prevent stockouts, while just-in-time inventory minimizes reorder points by synchronizing orders closely with production schedules to reduce holding costs.

Cycle Stock

Cycle stock represents the inventory portion replenished regularly to meet predictable demand, contrasting with safety stock's buffer strategy and Just-In-Time inventory's minimal holding approach.

Service Level Agreement (SLA)

Safety stock ensures high Service Level Agreement (SLA) compliance by buffering against demand variability, while Just-In-Time inventory minimizes holding costs but requires stringent SLA adherence through precise demand forecasting and supplier reliability.

Pull System

A pull system in Just-In-Time inventory minimizes safety stock by replenishing materials only as needed, reducing excess inventory and enhancing efficiency.

Safety Stock vs Just-In-Time Inventory Infographic

njnir.com

njnir.com