Heijunka, or production leveling, optimizes workflow by distributing production volume and variety evenly over time, reducing inventory and minimizing bottlenecks. One-piece flow emphasizes continuous movement of individual units through processes without delays, enhancing quality and reducing lead time. Combining Heijunka with one-piece flow creates a balanced system that improves operational efficiency and responsiveness in industrial engineering.

Table of Comparison

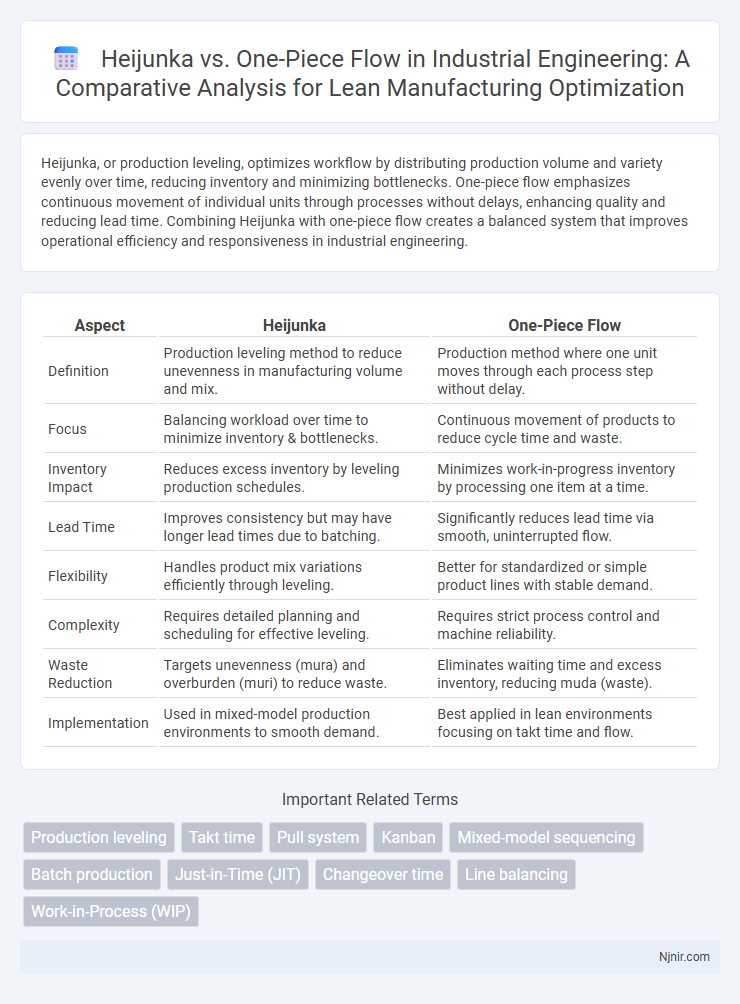

| Aspect | Heijunka | One-Piece Flow |

|---|---|---|

| Definition | Production leveling method to reduce unevenness in manufacturing volume and mix. | Production method where one unit moves through each process step without delay. |

| Focus | Balancing workload over time to minimize inventory & bottlenecks. | Continuous movement of products to reduce cycle time and waste. |

| Inventory Impact | Reduces excess inventory by leveling production schedules. | Minimizes work-in-progress inventory by processing one item at a time. |

| Lead Time | Improves consistency but may have longer lead times due to batching. | Significantly reduces lead time via smooth, uninterrupted flow. |

| Flexibility | Handles product mix variations efficiently through leveling. | Better for standardized or simple product lines with stable demand. |

| Complexity | Requires detailed planning and scheduling for effective leveling. | Requires strict process control and machine reliability. |

| Waste Reduction | Targets unevenness (mura) and overburden (muri) to reduce waste. | Eliminates waiting time and excess inventory, reducing muda (waste). |

| Implementation | Used in mixed-model production environments to smooth demand. | Best applied in lean environments focusing on takt time and flow. |

Introduction to Heijunka and One-Piece Flow

Heijunka, a Lean manufacturing technique, levels production by smoothing order variations to reduce waste and improve efficiency, while One-Piece Flow emphasizes manufacturing products one unit at a time for faster throughput and quality control. Heijunka promotes balanced workloads and consistent output to prevent bottlenecks, whereas One-Piece Flow focuses on minimizing work-in-process inventory and ensuring continuous movement. Both approaches optimize production but differ in handling batch sizes and inventory management to achieve Lean goals.

Key Principles of Heijunka

Heijunka emphasizes leveling production by smoothing type and volume over a fixed period to reduce variability and inventory, enabling consistent workflow. Its key principles include mixed-model sequencing, standardized work cycles, and takt time adherence to balance production capacity with customer demand. This contrasts with one-piece flow, which focuses on moving single units through each process step sequentially to minimize lead time and waste.

Key Principles of One-Piece Flow

One-piece flow maximizes efficiency by producing items one at a time, reducing waste and inventory buffer costs. Key principles include minimizing batch sizes, ensuring smooth workflow without interruptions, and promoting continuous movement through each production stage. This approach enhances quality control by detecting defects immediately, enabling faster response and improvement cycles.

Comparative Overview: Heijunka vs One-Piece Flow

Heijunka levels production by distributing work evenly over a set period, reducing inventory and smoothing workflow in manufacturing processes. One-piece flow emphasizes producing items one at a time through each step without batch delays, enhancing quality control and minimizing lead time. Comparing both, Heijunka optimizes production scheduling at a macro level, while one-piece flow focuses on micro-level efficiency in individual process steps.

Benefits of Using Heijunka in Industrial Engineering

Heijunka improves production stability by leveling workloads and reducing bottlenecks, leading to consistent output and minimized inventory costs. It enhances flexibility by smoothing fluctuations in demand, which supports just-in-time manufacturing and reduces lead times. Implementing Heijunka optimizes resource utilization and decreases waste, contributing to higher overall operational efficiency in industrial engineering processes.

Benefits of Implementing One-Piece Flow

One-piece flow enhances production efficiency by reducing work-in-progress inventory and minimizing lead times, resulting in faster response to customer demand. This approach improves quality control by enabling immediate detection and correction of defects, which decreases waste and rework costs. Implementing one-piece flow fosters a more balanced workload, leading to smoother operations and increased employee engagement on the production line.

Challenges in Adopting Heijunka Systems

Heijunka implementation often faces challenges related to demand variability and fluctuating production volumes, making it difficult to maintain a leveled schedule. Balancing product mix while minimizing inventory and avoiding bottlenecks requires precise forecasting and cross-functional coordination, which many organizations struggle to achieve. Unlike one-piece flow that emphasizes continuous movement of single units, Heijunka demands complex planning and system flexibility to handle batch leveling without compromising efficiency.

Obstacles in One-Piece Flow Implementation

One-piece flow implementation faces obstacles such as equipment variability, workforce skill gaps, and inconsistent material supply, which disrupt continuous production. Limited flexibility to handle product variation often causes bottlenecks and increases cycle time, reducing overall efficiency. In contrast, Heijunka's leveled production scheduling mitigates these challenges by balancing workloads and smoothing out fluctuations in demand.

Case Studies: Heijunka and One-Piece Flow in Practice

Case studies reveal that Heijunka significantly improves production stability by leveling workload and minimizing inventory fluctuations, as demonstrated in Toyota's assembly lines where demand variability is smoothed to enhance efficiency. One-piece flow, exemplified in electronics manufacturing plants, reduces lead times and defects by moving products through sequential steps without batch delays, increasing responsiveness and quality. Combining Heijunka with one-piece flow in automotive factories shows synergistic effects, balancing workload leveling with continuous flow to optimize resource utilization and throughput.

Choosing the Right Approach: Factors for Decision-Making

Choosing between Heijunka and One-piece flow depends on production volume, product variety, and demand predictability. Heijunka excels in leveling production to reduce inventory and smooth demand fluctuations, making it ideal for mixed-model assembly lines with high product variation. One-piece flow enhances quality and lead time by minimizing work-in-progress but is best suited for stable demand and standardized product lines.

Production leveling

Heijunka optimizes production leveling by evenly distributing workload and minimizing inventory, whereas one-piece flow emphasizes continuous, sequential production to reduce lead times and enhance quality.

Takt time

Heijunka balances production volume over time to align with Takt time, while One-piece flow emphasizes continuous movement of individual units matching the exact Takt time for minimal inventory and lead time.

Pull system

Heijunka balances production volume and variety through leveled scheduling in a pull system, while one-piece flow emphasizes continuous, single-unit movement to minimize inventory and lead time.

Kanban

Heijunka uses Kanban to level production and balance workflow, while one-piece flow employs Kanban signals to ensure continuous, single-unit processing without bottlenecks.

Mixed-model sequencing

Heijunka optimizes mixed-model sequencing by leveling production volume and variety over time, while one-piece flow emphasizes continuous movement of individual units to minimize inventory and reduce lead time.

Batch production

Heijunka reduces batch production variability by leveling workload and mixing product types, whereas one-piece flow eliminates batches by producing items sequentially to minimize inventory and lead time.

Just-in-Time (JIT)

Heijunka balances production volume and type to support Just-in-Time (JIT) by reducing variability, while One-piece flow emphasizes minimizing inventory and lead time for continuous JIT delivery.

Changeover time

Heijunka minimizes changeover time by leveling production volume and variety, while one-piece flow reduces changeover time by producing single units sequentially for faster transitions.

Line balancing

Heijunka evenly distributes production volume and mix to optimize line balancing, while one-piece flow focuses on continuous movement of single units, enhancing takt time alignment but requiring precise synchronization for balanced workload.

Work-in-Process (WIP)

Heijunka minimizes Work-in-Process (WIP) by leveling production volume and variety to stabilize workflow, while One-piece flow reduces WIP by moving items through each production stage individually for continuous processing.

Heijunka vs One-piece flow Infographic

njnir.com

njnir.com