Data-driven quality control leverages advanced analytics and real-time data to identify defects with higher accuracy and consistency compared to manual inspection. This method reduces human error, accelerates decision-making, and enables predictive maintenance to prevent future issues. Integrating automated data collection systems enhances overall efficiency and product reliability in industrial processes.

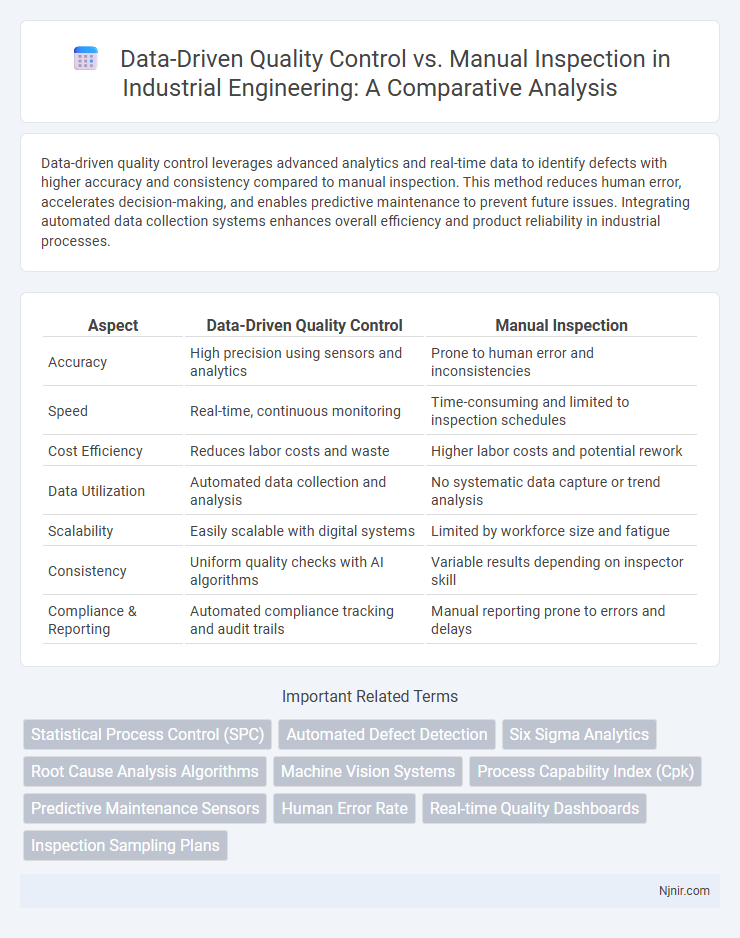

Table of Comparison

| Aspect | Data-Driven Quality Control | Manual Inspection |

|---|---|---|

| Accuracy | High precision using sensors and analytics | Prone to human error and inconsistencies |

| Speed | Real-time, continuous monitoring | Time-consuming and limited to inspection schedules |

| Cost Efficiency | Reduces labor costs and waste | Higher labor costs and potential rework |

| Data Utilization | Automated data collection and analysis | No systematic data capture or trend analysis |

| Scalability | Easily scalable with digital systems | Limited by workforce size and fatigue |

| Consistency | Uniform quality checks with AI algorithms | Variable results depending on inspector skill |

| Compliance & Reporting | Automated compliance tracking and audit trails | Manual reporting prone to errors and delays |

Introduction to Quality Control in Industrial Engineering

Data-driven quality control leverages real-time sensor data, machine learning algorithms, and statistical process control to detect defects and optimize production efficiency in industrial engineering. Manual inspection relies on human expertise and visual assessment, which can introduce variability and slower response times in identifying quality issues. Integrating data-driven methods enhances consistency, accelerates decision-making, and enables predictive maintenance compared to traditional manual inspection approaches.

The Evolution from Manual Inspection to Data-Driven Methods

The evolution from manual inspection to data-driven quality control marks a significant shift in manufacturing and production processes, driven by advances in machine learning, artificial intelligence, and sensor technologies. Data-driven methods leverage real-time analytics and predictive modeling to identify defects with greater accuracy and speed compared to traditional manual inspection, which often suffers from human error and inconsistency. This transformation enhances product quality, reduces operational costs, and fosters continuous improvement through actionable insights derived from vast datasets.

Core Principles of Manual Inspection

Manual inspection relies on human expertise to identify defects through visual and tactile examination, emphasizing sensory perception and experience-based judgment. It prioritizes thoroughness, adaptability, and contextual understanding, allowing inspectors to detect subtle anomalies that automated systems might miss. This hands-on approach ensures nuanced quality assessments by integrating operator intuition with standardized criteria.

Key Technologies in Data-Driven Quality Control

Data-driven quality control leverages advanced technologies such as machine learning algorithms, real-time sensor data integration, and automated image recognition to enhance accuracy and efficiency in defect detection. Industrial IoT (IIoT) devices enable continuous monitoring and data collection, facilitating predictive analytics and reducing reliance on human error inherent in manual inspection. These technologies optimize process control, ensure consistent product quality, and support adaptive quality management systems in manufacturing environments.

Accuracy and Reliability Comparison

Data-driven quality control leverages advanced analytics and real-time sensor data to achieve higher accuracy by minimizing human error and inconsistencies inherent in manual inspection processes. Automated systems consistently detect defects with greater precision, ensuring reliable quality standards across large production volumes, whereas manual inspection often suffers from subjective judgment and fatigue, reducing reliability. Enhanced traceability and data logging in data-driven approaches further improve defect tracking, leading to more reliable quality assurance outcomes than traditional manual methods.

Efficiency and Productivity Impact

Data-driven quality control leverages advanced analytics and automated sensors to identify defects faster and more accurately than manual inspection, significantly reducing error rates and downtime. Automation in data-driven systems accelerates throughput, enhances consistency, and allows real-time monitoring, resulting in higher productivity and optimized resource allocation. Manual inspection, while flexible for complex or nuanced assessments, often causes bottlenecks due to slower processing speeds and human variability, limiting overall efficiency in high-volume manufacturing environments.

Cost Analysis: Data-Driven vs Manual Approaches

Data-driven quality control reduces operational costs by minimizing human error and enabling real-time monitoring, leading to fewer defects and less rework. Manual inspection incurs higher labor expenses and slower throughput, increasing overall production costs due to inconsistency and delayed defect detection. Investing in automated data analytics yields long-term savings by optimizing resource allocation and improving process efficiency.

Skill Requirements and Workforce Implications

Data-driven quality control requires advanced skills in data analysis, machine learning, and digital tools competency, shifting workforce demand towards technical expertise and continuous training. Manual inspection relies heavily on human sensory skills and experience but may face challenges in scalability and consistency due to subjective judgment and fatigue. Transitioning to data-driven systems influences workforce implications by promoting upskilling, reducing manual labor dependence, and enabling more strategic roles focused on interpreting data insights.

Integration with Smart Manufacturing Systems

Data-driven quality control integrates real-time sensor data and machine learning algorithms within smart manufacturing systems, enabling continuous monitoring and automatic defect detection. This approach enhances accuracy and speed by reducing human error compared to manual inspection, which relies on subjective visual assessment and periodic checks. Integration with IoT platforms and advanced analytics allows seamless feedback loops for process optimization, significantly improving manufacturing efficiency and product consistency.

Future Trends in Industrial Quality Control

Data-driven quality control harnesses advanced sensor technologies, machine learning algorithms, and real-time analytics to enhance defect detection accuracy and reduce human error in manufacturing processes. Future trends in industrial quality control emphasize the integration of AI-powered predictive maintenance, automated visual inspection systems, and IoT connectivity to create smarter, more adaptive production lines. These innovations enable continuous data collection and rapid feedback loops, fostering increased efficiency, reduced downtime, and higher product consistency compared to traditional manual inspection methods.

Statistical Process Control (SPC)

Data-driven quality control leveraging Statistical Process Control (SPC) enhances accuracy and efficiency by continuously monitoring process variability, unlike manual inspection which relies on subjective, intermittent evaluations.

Automated Defect Detection

Automated defect detection in data-driven quality control significantly enhances accuracy and efficiency compared to manual inspection by utilizing advanced algorithms and real-time data analysis.

Six Sigma Analytics

Data-driven quality control using Six Sigma Analytics enhances defect detection accuracy and process efficiency compared to traditional manual inspection by leveraging real-time data and statistical analysis.

Root Cause Analysis Algorithms

Data-driven quality control leverages Root Cause Analysis algorithms to efficiently identify and address underlying defects, significantly surpassing the accuracy and speed of manual inspection methods.

Machine Vision Systems

Machine Vision Systems enhance data-driven quality control by delivering precise, real-time defect detection and analytics, outperforming traditional manual inspection in speed, accuracy, and consistency.

Process Capability Index (Cpk)

Data-driven quality control enhances Process Capability Index (Cpk) accuracy and consistency compared to manual inspection by leveraging real-time data and statistical analysis.

Predictive Maintenance Sensors

Predictive maintenance sensors enable data-driven quality control by continuously monitoring equipment conditions and detecting anomalies earlier and more accurately than manual inspection methods.

Human Error Rate

Data-driven quality control reduces human error rates by automating inspections with precise algorithms, while manual inspection relies on subjective human judgment prone to inconsistencies and higher error rates.

Real-time Quality Dashboards

Real-time quality dashboards in data-driven quality control enable immediate detection and correction of defects, significantly outperforming manual inspection by providing continuous, accurate, and actionable insights.

Inspection Sampling Plans

Data-driven quality control enhances inspection sampling plans by leveraging real-time analytics to optimize sample sizes and defect detection rates, outperforming traditional manual inspection methods in accuracy and efficiency.

Data-driven quality control vs Manual inspection Infographic

njnir.com

njnir.com