Root cause analysis (RCA) identifies the fundamental cause of failures after they occur, enabling targeted corrective actions to prevent recurrence. Failure mode and effects analysis (FMEA) is a proactive tool that assesses potential failure modes in processes or products to prioritize risks before issues arise. Both methodologies enhance reliability and safety but differ in timing and focus within industrial engineering problem-solving.

Table of Comparison

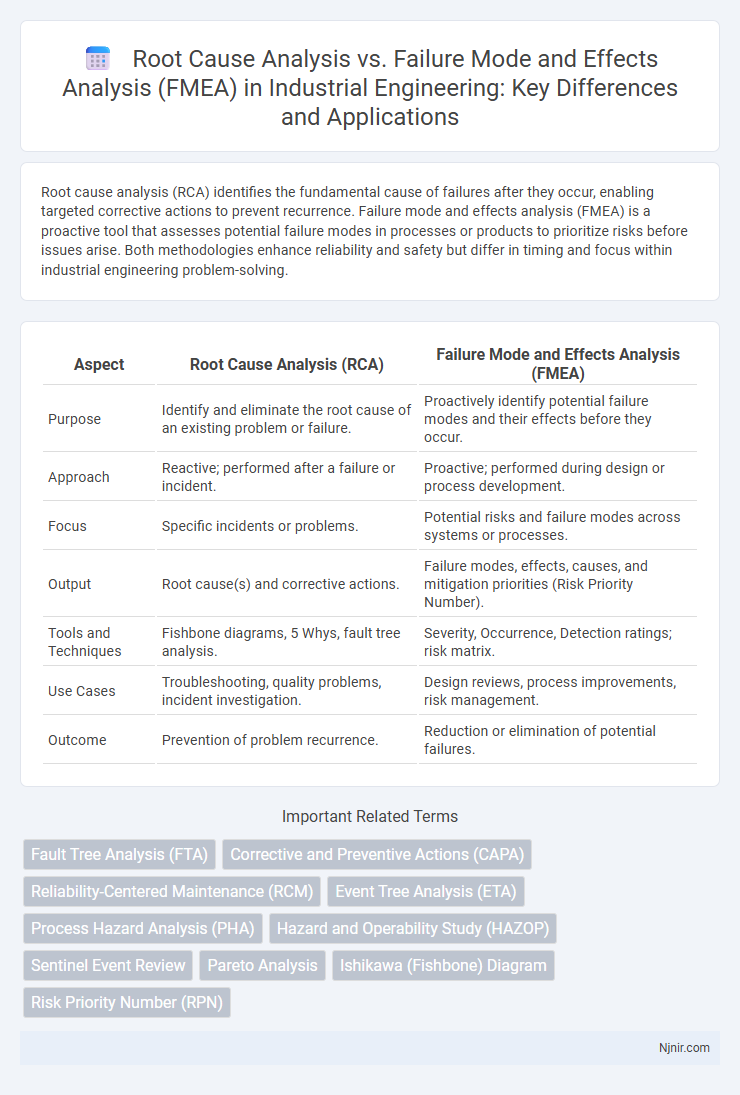

| Aspect | Root Cause Analysis (RCA) | Failure Mode and Effects Analysis (FMEA) |

|---|---|---|

| Purpose | Identify and eliminate the root cause of an existing problem or failure. | Proactively identify potential failure modes and their effects before they occur. |

| Approach | Reactive; performed after a failure or incident. | Proactive; performed during design or process development. |

| Focus | Specific incidents or problems. | Potential risks and failure modes across systems or processes. |

| Output | Root cause(s) and corrective actions. | Failure modes, effects, causes, and mitigation priorities (Risk Priority Number). |

| Tools and Techniques | Fishbone diagrams, 5 Whys, fault tree analysis. | Severity, Occurrence, Detection ratings; risk matrix. |

| Use Cases | Troubleshooting, quality problems, incident investigation. | Design reviews, process improvements, risk management. |

| Outcome | Prevention of problem recurrence. | Reduction or elimination of potential failures. |

Introduction to Root Cause Analysis and FMEA

Root Cause Analysis (RCA) systematically identifies underlying causes of problems to prevent recurrence, emphasizing causal relationships and corrective actions. Failure Mode and Effects Analysis (FMEA) proactively evaluates potential failure modes within processes or products, assessing severity, occurrence, and detection to prioritize risk mitigation. Both tools enhance quality management by targeting issues through analysis but differ in timing--RCA addresses incidents after they occur, while FMEA anticipates failures before they happen.

Defining Root Cause Analysis in Industrial Engineering

Root Cause Analysis (RCA) in industrial engineering is a systematic process used to identify the fundamental causes of defects or failures in manufacturing systems and processes. It focuses on tracing problems back to their origin to prevent recurrence and improve process reliability. Unlike Failure Mode and Effects Analysis (FMEA), which anticipates potential failure modes and their effects before issues occur, RCA is applied after a failure to diagnose and address the underlying issues.

Understanding Failure Mode and Effects Analysis (FMEA)

Failure Mode and Effects Analysis (FMEA) is a systematic approach used to identify potential failure modes within a system, assess their causes and effects, and prioritize actions to mitigate risks before failures occur. It focuses on evaluating the severity, occurrence, and detectability of each failure mode to enhance reliability and safety in design and processes. FMEA differs from Root Cause Analysis (RCA), which investigates failures after they happen to determine underlying causes and prevent recurrence.

Key Objectives: RCA vs FMEA

Root Cause Analysis (RCA) focuses on identifying the underlying causes of a specific problem or failure to prevent recurrence, emphasizing problem-solving based on past events. Failure Mode and Effects Analysis (FMEA) aims to proactively identify potential failure modes and assess their impact to prioritize mitigation actions before failures occur. RCA targets reactive solutions for known issues, while FMEA prioritizes risk reduction through early detection and prevention.

Methodologies: Step-by-Step Comparison

Root cause analysis (RCA) systematically identifies the underlying causes of a problem by collecting data, analyzing contributing factors, and implementing corrective actions through a structured approach like the 5 Whys or Fishbone Diagram. Failure Mode and Effects Analysis (FMEA) prioritizes potential failures by ranking their severity, occurrence, and detectability using a risk priority number (RPN) to prevent issues before they arise. While RCA is reactive and focuses on resolving existing problems, FMEA is proactive, aiming to anticipate and mitigate possible failures during the design or process stages.

Tools and Techniques Used in RCA and FMEA

Root Cause Analysis (RCA) employs tools such as the 5 Whys, Fishbone Diagram (Ishikawa), and Pareto Analysis to systematically identify the fundamental cause of a problem. Failure Mode and Effects Analysis (FMEA) utilizes a structured approach including Risk Priority Number (RPN) calculation, severity, occurrence, and detection ratings to evaluate potential failure modes and their effects on system performance. Both methodologies incorporate data collection and process mapping, but RCA targets cause identification after an event, while FMEA proactively assesses potential failures to prevent defects.

Applications in Industrial Engineering Environments

Root cause analysis (RCA) identifies underlying causes of defects or failures, enabling targeted corrective actions in manufacturing processes and production lines. Failure Mode and Effects Analysis (FMEA) systematically evaluates potential failure modes, their causes, and effects to prioritize risk mitigation efforts in product design and process improvement. Both tools are integral in industrial engineering for enhancing quality control, minimizing downtime, and optimizing operational efficiency in complex industrial systems.

Strengths and Limitations of RCA and FMEA

Root Cause Analysis (RCA) excels in identifying the underlying causes of specific failures, providing deep insights for resolving recurring problems but can be time-consuming and reactive. Failure Mode and Effects Analysis (FMEA) offers a proactive approach by systematically evaluating potential failure modes and their impacts, enhancing risk mitigation during design or process stages, yet it may overlook complex or unforeseen failure interactions. Both methods complement each other; RCA uncovers root causes post-failure, while FMEA anticipates risks to prevent failures, though their effectiveness depends on thorough data collection and expertise.

Integration of RCA and FMEA in Continuous Improvement Programs

Integrating Root Cause Analysis (RCA) and Failure Mode and Effects Analysis (FMEA) within Continuous Improvement Programs enhances problem-solving efficiency by combining RCA's in-depth identification of underlying causes with FMEA's proactive risk assessment and prioritization of potential failures. This fusion enables organizations to not only address existing issues systematically but also to anticipate and mitigate future risks, resulting in improved product quality, reliability, and operational performance. Effective integration leverages data-driven insights from both methodologies to drive sustainable process improvements and reduce downtime.

Choosing the Right Approach for Industrial Problems

Root cause analysis (RCA) targets identifying the fundamental reason behind a specific industrial failure, making it ideal for addressing urgent or unexpected breakdowns. Failure mode and effects analysis (FMEA) proactively evaluates potential failure points within a process or product, prioritizing risks to prevent future issues. Selecting the appropriate method depends on whether the goal is reactive problem-solving with RCA or proactive risk mitigation with FMEA in industrial environments.

Fault Tree Analysis (FTA)

Fault Tree Analysis (FTA) is a top-down, deductive failure analysis method that systematically identifies root causes of system failures, differentiating it from Failure Mode and Effects Analysis (FMEA), which is a bottom-up, inductive approach focusing on potential failure modes and their effects.

Corrective and Preventive Actions (CAPA)

Root Cause Analysis (RCA) identifies underlying causes of failures for targeted Corrective Actions, while Failure Mode and Effects Analysis (FMEA) proactively predicts potential failure modes to implement Preventive Actions within the CAPA framework.

Reliability-Centered Maintenance (RCM)

Root cause analysis identifies the underlying reasons for failures to improve Reliability-Centered Maintenance (RCM), while Failure Mode and Effects Analysis (FMEA) proactively assesses potential failure modes and their impacts to enhance RCM strategies.

Event Tree Analysis (ETA)

Event Tree Analysis (ETA) rigorously complements Root Cause Analysis and Failure Mode and Effects Analysis (FMEA) by systematically mapping potential event sequences and their outcomes to identify risk probabilities and failure impacts.

Process Hazard Analysis (PHA)

Root cause analysis identifies underlying causes of process failures, while Failure Mode and Effects Analysis (FMEA) systematically evaluates potential failure modes and their impacts as key components of Process Hazard Analysis (PHA) to enhance industrial safety.

Hazard and Operability Study (HAZOP)

Hazard and Operability Study (HAZOP) is a qualitative risk assessment technique complementing Root Cause Analysis and FMEA by systematically identifying hazards and operability issues in complex processes to improve safety and reliability.

Sentinel Event Review

Sentinel Event Review prioritizes identifying root causes through detailed Root Cause Analysis while FMEA systematically evaluates potential failure modes to prevent sentinel events in healthcare settings.

Pareto Analysis

Pareto Analysis in Root Cause Analysis identifies the most significant causes by frequency or impact, while in Failure Mode and Effects Analysis (FMEA), it prioritizes failure modes based on risk priority numbers to focus mitigation efforts on the critical few.

Ishikawa (Fishbone) Diagram

The Ishikawa (Fishbone) Diagram is a key tool in Root Cause Analysis for visually identifying potential causes of problems, whereas Failure Mode and Effects Analysis (FMEA) systematically evaluates failure modes and their impacts to prioritize risks.

Risk Priority Number (RPN)

Failure Mode and Effects Analysis (FMEA) utilizes the Risk Priority Number (RPN) to quantify and prioritize potential failure risks, whereas Root Cause Analysis identifies underlying causes of failures without relying on RPN metrics.

Root cause analysis vs Failure mode and effects analysis (FMEA) Infographic

njnir.com

njnir.com