Just-In-Time (JIT) inventory management minimizes waste and reduces holding costs by synchronizing production schedules with demand forecasts, ensuring materials arrive precisely when needed. Just-In-Case (JIC) maintains excess inventory to safeguard against supply chain disruptions, prioritizing reliability over efficiency. Balancing JIT and JIC strategies enables industrial engineers to optimize inventory control, improve cash flow, and maintain operational resilience.

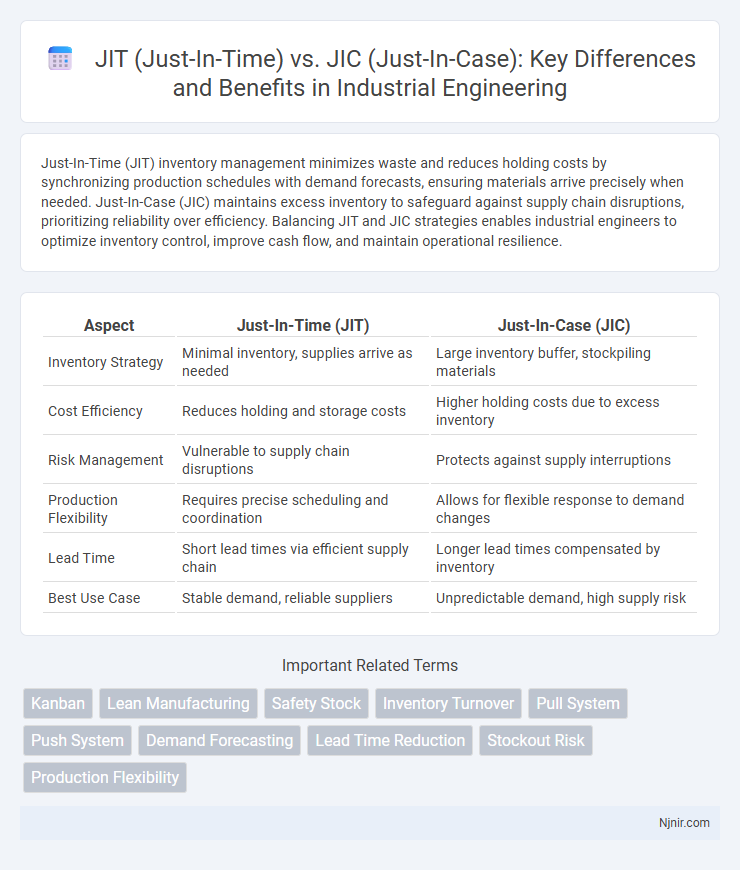

Table of Comparison

| Aspect | Just-In-Time (JIT) | Just-In-Case (JIC) |

|---|---|---|

| Inventory Strategy | Minimal inventory, supplies arrive as needed | Large inventory buffer, stockpiling materials |

| Cost Efficiency | Reduces holding and storage costs | Higher holding costs due to excess inventory |

| Risk Management | Vulnerable to supply chain disruptions | Protects against supply interruptions |

| Production Flexibility | Requires precise scheduling and coordination | Allows for flexible response to demand changes |

| Lead Time | Short lead times via efficient supply chain | Longer lead times compensated by inventory |

| Best Use Case | Stable demand, reliable suppliers | Unpredictable demand, high supply risk |

Introduction to JIT and JIC in Industrial Engineering

Just-In-Time (JIT) in Industrial Engineering emphasizes minimizing inventory by synchronizing production schedules closely with demand, reducing waste and enhancing efficiency. Just-In-Case (JIC) builds buffer stock to manage uncertainties and prevent disruptions in supply chains, prioritizing reliability over lean inventory. Both strategies address inventory management but diverge on balancing cost control with risk mitigation.

Core Principles of Just-In-Time Systems

Just-In-Time (JIT) systems prioritize minimizing inventory by producing goods only as needed, reducing waste and enhancing efficiency through precise demand forecasting and streamlined workflows. Core principles include continuous improvement (Kaizen), waste elimination (Muda), and synchronization of production with customer demand, enabling lean operations and cost savings. JIT contrasts with Just-In-Case (JIC) systems, which emphasize stockpiling inventory to mitigate supply chain disruptions but often result in higher holding costs and inefficiencies.

Fundamentals of Just-In-Case Inventory Strategies

Just-In-Case (JIC) inventory strategies prioritize maintaining high stock levels to mitigate risks associated with supply chain disruptions, demand fluctuations, and unforeseen delays. This approach ensures operational continuity by creating buffer inventory, which contrasts sharply with Just-In-Time (JIT) methods that emphasize minimal inventory holding and lean operations. JIC fundamentally relies on forecasting accuracy and safety stock calculations to balance carrying costs against service level requirements, aiming to prevent stockouts and support customer satisfaction.

Comparative Analysis: JIT vs JIC

JIT (Just-In-Time) inventory management minimizes holding costs by receiving materials only as they are needed in the production process, increasing efficiency but risking supply chain disruptions. JIC (Just-In-Case) maintains higher inventory levels to safeguard against uncertainties and demand spikes, ensuring product availability but incurring higher storage and capital costs. Companies adopting JIT benefit from lean operations and reduced waste, while those using JIC prioritize reliability and flexibility to mitigate supply chain risks.

Impact on Supply Chain Efficiency

JIT (Just-In-Time) minimizes inventory levels by delivering materials exactly when needed, significantly reducing storage costs and waste while increasing supply chain responsiveness and efficiency. In contrast, JIC (Just-In-Case) maintains higher inventory buffers to mitigate risks of supply disruptions, which can lead to increased holding costs and potential overstocking but provides greater security against demand variability. The choice between JIT and JIC directly impacts supply chain agility, cost structure, and risk management strategies, with JIT favoring lean operations and JIC prioritizing supply continuity.

Cost Implications in JIT and JIC Approaches

JIT (Just-In-Time) reduces inventory carrying costs by minimizing stock levels, leading to lower warehousing expenses and less capital tied up in inventory. In contrast, JIC (Just-In-Case) incurs higher costs due to maintaining large safety stocks, resulting in increased storage, insurance, and potential obsolescence expenses. Companies implementing JIT must invest in reliable supply chain coordination to avoid stockouts, while JIC approaches prioritize cost security with elevated inventory management overhead.

Risk Management and Flexibility Considerations

JIT (Just-In-Time) inventory management minimizes waste and reduces holding costs by synchronizing supply with demand but increases vulnerability to supply chain disruptions, posing significant risk management challenges. JIC (Just-In-Case) maintains higher inventory levels to buffer against uncertainties, enhancing operational flexibility and reducing the risk of stockouts during demand spikes or supply interruptions. Effective risk management requires balancing JIT efficiency with JIC's safety stock strategy to ensure resilience without excessive carrying costs.

Quality Control under JIT and JIC Models

Quality control in Just-In-Time (JIT) systems emphasizes defect prevention through continuous inspections and real-time feedback, reducing waste and enhancing efficiency by producing only what is needed. Just-In-Case (JIC) quality control relies on maintaining buffer inventory and rigorous end-of-line inspections to catch defects before products reach customers, ensuring reliability despite potential supply chain disruptions. The JIT model demands a proactive quality culture and quick response to errors, while JIC prioritizes stockpiled safety margins to absorb variability and defects.

Case Studies: Industry Applications of JIT and JIC

Case studies reveal automotive giants like Toyota leveraging JIT to minimize inventory costs and enhance efficiency through real-time demand-driven production. Conversely, aerospace firms such as Boeing implement JIC strategies, maintaining substantial inventory buffers to mitigate supply chain disruptions and ensure continuous production. These contrasting approaches highlight the industry-specific balance between lean inventory management and risk aversion required for operational resilience.

Future Trends in Inventory Management

Future trends in inventory management emphasize the integration of Just-In-Time (JIT) and Just-In-Case (JIC) strategies through advanced AI-driven demand forecasting and real-time data analytics. Hybrid inventory models leverage predictive analytics to optimize stock levels, minimizing excess inventory typical of JIC while preserving JIT's efficiency in reducing waste and lead times. Emerging supply chain technologies, such as blockchain and IoT, further enhance transparency and responsiveness, enabling firms to dynamically adjust between JIT and JIC approaches based on fluctuating market conditions and risk profiles.

Kanban

Kanban enhances JIT inventory management by visualizing workflow and minimizing waste, whereas JIC relies on maintaining excess stock to mitigate supply risk.

Lean Manufacturing

Lean Manufacturing prioritizes JIT (Just-In-Time) by minimizing inventory and waste through demand-driven production, contrasting with JIC (Just-In-Case) which maintains excess inventory as a buffer against uncertainty.

Safety Stock

JIC (Just-In-Case) maintains higher safety stock levels to mitigate supply chain disruptions, whereas JIT (Just-In-Time) minimizes safety stock to reduce inventory costs and enhance operational efficiency.

Inventory Turnover

JIT (Just-In-Time) significantly increases inventory turnover by minimizing stock levels and reducing holding costs, whereas JIC (Just-In-Case) lowers inventory turnover due to maintaining higher safety stock to mitigate supply chain disruptions.

Pull System

The Pull System in JIT (Just-In-Time) minimizes inventory and reduces waste by producing goods only as needed, contrasting with JIC (Just-In-Case), which maintains excess stock to mitigate supply chain disruptions.

Push System

The Push System in inventory management often aligns with JIC (Just-In-Case) strategies, emphasizing stock accumulation based on forecasted demand to prevent shortages, unlike JIT (Just-In-Time) which minimizes inventory by producing goods only as needed.

Demand Forecasting

JIT relies on precise demand forecasting to minimize inventory and reduce waste, while JIC uses conservative demand estimates to maintain higher safety stock and buffer against supply uncertainties.

Lead Time Reduction

Just-In-Time (JIT) minimizes lead time by synchronizing production with demand, whereas Just-In-Case (JIC) increases lead time due to buffer inventory and precautionary stockholding.

Stockout Risk

JIT minimizes stockout risk by relying on precise demand forecasting and fast replenishment, while JIC reduces stockout risk through maintaining higher inventory levels as a buffer against uncertainties.

Production Flexibility

JIT production enhances flexibility by minimizing inventory and enabling rapid response to demand changes, while JIC production maintains higher inventory levels to ensure readiness at the cost of reduced adaptability.

JIT (Just-In-Time) vs JIC (Just-In-Case) Infographic

njnir.com

njnir.com