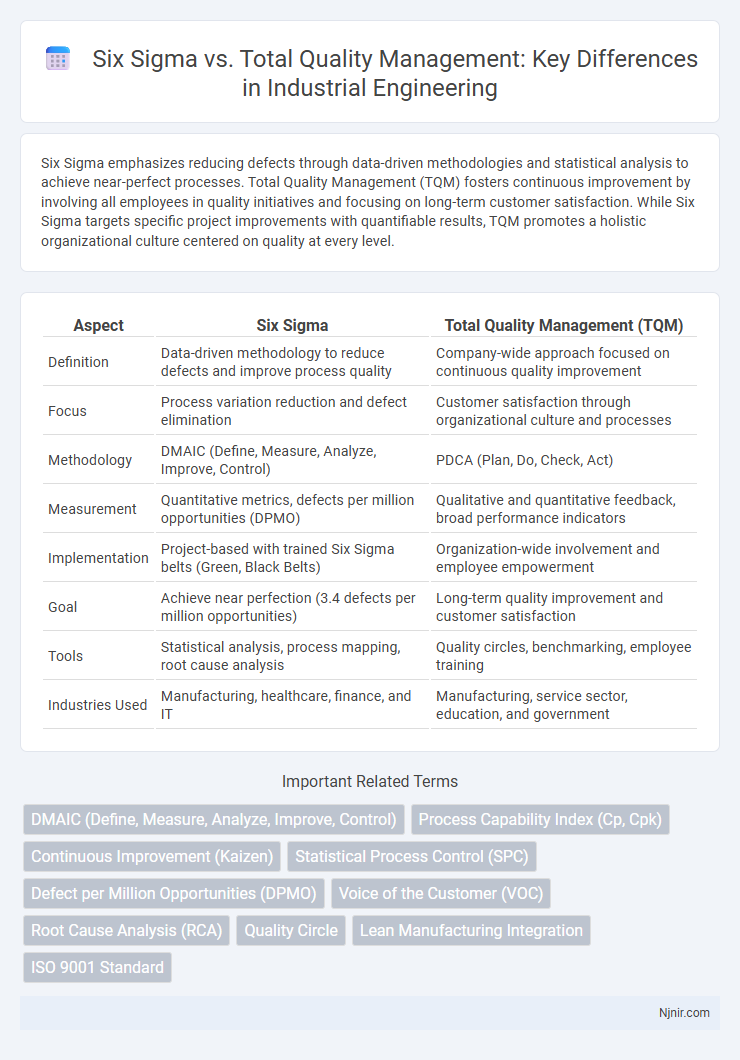

Six Sigma emphasizes reducing defects through data-driven methodologies and statistical analysis to achieve near-perfect processes. Total Quality Management (TQM) fosters continuous improvement by involving all employees in quality initiatives and focusing on long-term customer satisfaction. While Six Sigma targets specific project improvements with quantifiable results, TQM promotes a holistic organizational culture centered on quality at every level.

Table of Comparison

| Aspect | Six Sigma | Total Quality Management (TQM) |

|---|---|---|

| Definition | Data-driven methodology to reduce defects and improve process quality | Company-wide approach focused on continuous quality improvement |

| Focus | Process variation reduction and defect elimination | Customer satisfaction through organizational culture and processes |

| Methodology | DMAIC (Define, Measure, Analyze, Improve, Control) | PDCA (Plan, Do, Check, Act) |

| Measurement | Quantitative metrics, defects per million opportunities (DPMO) | Qualitative and quantitative feedback, broad performance indicators |

| Implementation | Project-based with trained Six Sigma belts (Green, Black Belts) | Organization-wide involvement and employee empowerment |

| Goal | Achieve near perfection (3.4 defects per million opportunities) | Long-term quality improvement and customer satisfaction |

| Tools | Statistical analysis, process mapping, root cause analysis | Quality circles, benchmarking, employee training |

| Industries Used | Manufacturing, healthcare, finance, and IT | Manufacturing, service sector, education, and government |

Introduction to Six Sigma and Total Quality Management

Six Sigma is a data-driven methodology aimed at reducing defects and variability in processes to enhance quality and efficiency, utilizing statistical tools and disciplined project management techniques. Total Quality Management (TQM) emphasizes continuous improvement through employee involvement and customer-focused strategies, fostering a culture where quality is integral to all organizational processes. Both approaches seek to improve organizational performance but differ in scope, tools, and implementation strategies, with Six Sigma focusing on precise quantification and TQM on holistic quality culture.

Core Principles of Six Sigma

Six Sigma centers on reducing process variation and enhancing quality through data-driven decision-making, emphasizing the DMAIC methodology--Define, Measure, Analyze, Improve, and Control. It targets achieving near-perfect quality with a defect rate of 3.4 per million opportunities by applying statistical tools and rigorous problem-solving techniques. Unlike Total Quality Management (TQM), which promotes continuous improvement across all organizational levels, Six Sigma focuses on strategic projects with quantifiable financial returns and precise metrics.

Fundamental Concepts of Total Quality Management

Total Quality Management (TQM) emphasizes continuous improvement, customer focus, and employee involvement to achieve long-term organizational success through quality enhancement. It integrates company-wide quality principles into every process and decision, promoting a culture of collaboration and prevention over detection. Core concepts include process-centered approaches, systematic problem-solving, and leadership commitment to quality at all levels.

Methodological Differences: Six Sigma vs TQM

Six Sigma employs a data-driven, statistical approach centered on reducing process variation and defects through DMAIC (Define, Measure, Analyze, Improve, Control) methodology, emphasizing measurable financial returns. Total Quality Management (TQM) focuses on continuous quality improvement involving all employees and stakeholders, promoting a cultural change and customer satisfaction without rigid statistical tools. Unlike TQM's broad, philosophy-based practices, Six Sigma provides a structured, project-oriented framework with quantifiable metrics and specific roles like Black Belts and Green Belts.

Tools and Techniques: Comparing Six Sigma and TQM

Six Sigma utilizes statistical analysis tools like DMAIC (Define, Measure, Analyze, Improve, Control), process mapping, and root cause analysis to reduce defects and variability. Total Quality Management (TQM) emphasizes qualitative tools such as PDCA (Plan, Do, Check, Act), employee involvement, and continuous improvement practices to enhance overall organizational quality. Both methodologies employ data-driven decision-making but differ in their approach, with Six Sigma focusing more on quantitative precision and TQM on comprehensive cultural change.

Implementation Strategies in Industrial Engineering

Six Sigma implementation in industrial engineering emphasizes data-driven methodologies, rigorous statistical analysis, and DMAIC (Define, Measure, Analyze, Improve, Control) phases to reduce process variation and defects. Total Quality Management (TQM) focuses on company-wide cultural change, continuous improvement, and employee involvement with tools like PDCA (Plan, Do, Check, Act) to enhance overall quality standards. Integrating Six Sigma's structured approach with TQM's holistic management philosophy often yields superior process optimization and operational excellence in industrial environments.

Impact on Process Improvement and Efficiency

Six Sigma drives process improvement through data-driven methodologies that reduce defects to 3.4 per million opportunities, significantly enhancing efficiency in manufacturing and service sectors. Total Quality Management (TQM) emphasizes a holistic, organization-wide culture of continuous improvement, fostering collaboration and employee involvement to optimize processes broadly. Both strategies improve quality, but Six Sigma delivers quantifiable, statistically measurable results, while TQM promotes sustainable, incremental efficiency gains through collective responsibility.

Roles of Leadership in Six Sigma and TQM

Leadership in Six Sigma drives data-driven decision-making by championing project selection and resource allocation, ensuring rigorous process improvements through defined roles such as Champions and Black Belts. In Total Quality Management (TQM), leadership fosters an organizational culture centered on continuous improvement and customer satisfaction, emphasizing employee involvement and collaborative problem-solving across all levels. Both frameworks require committed leaders who promote accountability and empower teams to sustain quality enhancements.

Real-World Case Studies: Successes and Challenges

Six Sigma has driven significant success in companies like General Electric by reducing defects and improving process efficiency, while Total Quality Management (TQM) has been effective at fostering a culture of continuous improvement in organizations such as Toyota. Real-world case studies reveal that Six Sigma excels in data-driven problem solving and measurable results, yet challenges include high implementation costs and complexity. In contrast, TQM emphasizes employee involvement and long-term cultural change but sometimes struggles with consistent metrics and slower impact on financial performance.

Choosing the Right Approach for Industrial Engineering

Choosing between Six Sigma and Total Quality Management (TQM) in industrial engineering hinges on specific organizational goals and process needs; Six Sigma emphasizes data-driven defect reduction and process variability control through DMAIC methodology, while TQM fosters a holistic culture of continuous improvement and employee involvement across all departments. Industrial engineers should assess factors such as the desired speed of implementation, scope of quality improvement, resource availability, and long-term sustainability when selecting the appropriate approach. Integrating metrics like defect rates, customer satisfaction indexes, and cost impact analysis helps determine which strategy delivers optimal operational efficiency and competitive advantage.

DMAIC (Define, Measure, Analyze, Improve, Control)

Six Sigma's DMAIC methodology provides a structured, data-driven approach to quality improvement, while Total Quality Management emphasizes continuous, organization-wide quality enhancement through employee involvement.

Process Capability Index (Cp, Cpk)

Six Sigma utilizes Process Capability Index (Cp, Cpk) metrics to statistically measure and improve process performance, whereas Total Quality Management (TQM) emphasizes overall organizational quality culture without primarily focusing on Cp and Cpk values.

Continuous Improvement (Kaizen)

Six Sigma emphasizes data-driven problem-solving and defect reduction through DMAIC cycles, while Total Quality Management integrates Continuous Improvement (Kaizen) as a cultural philosophy promoting incremental, organization-wide enhancements in quality and processes.

Statistical Process Control (SPC)

Six Sigma utilizes Statistical Process Control (SPC) to systematically reduce process variation and defects, whereas Total Quality Management (TQM) incorporates SPC as one of many tools for continuous quality improvement without a primary focus on statistical methods.

Defect per Million Opportunities (DPMO)

Six Sigma targets reducing Defects per Million Opportunities (DPMO) to 3.4, while Total Quality Management (TQM) emphasizes continuous quality improvement without a specific DPMO benchmark.

Voice of the Customer (VOC)

Six Sigma prioritizes Voice of the Customer (VOC) through data-driven analysis to reduce defects, while Total Quality Management (TQM) emphasizes continuous improvement and customer satisfaction by integrating VOC into organizational culture.

Root Cause Analysis (RCA)

Six Sigma uses structured Root Cause Analysis tools like DMAIC to systematically identify and eliminate defects, while Total Quality Management emphasizes continuous improvement and employee involvement in root cause identification.

Quality Circle

Quality Circles in Total Quality Management emphasize collaborative problem-solving and employee involvement, whereas Six Sigma focuses on data-driven process improvement and defect reduction.

Lean Manufacturing Integration

Six Sigma enhances Lean Manufacturing integration by using data-driven DMAIC methodology to reduce process variation, while Total Quality Management fosters continuous improvement through employee involvement and strategic quality culture alignment.

ISO 9001 Standard

Six Sigma and Total Quality Management (TQM) both aim to improve organizational processes, with Six Sigma emphasizing statistical analysis and defect reduction, while TQM focuses on continuous improvement and customer satisfaction, all aligned with the ISO 9001 standard's requirements for quality management systems and consistent process control.

Six Sigma vs Total Quality Management Infographic

njnir.com

njnir.com